Water stop device for preventing water leakage of through hole and processing method thereof

A technology of a water-stop device and a processing method, which is applied to vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of difficult to control the flow direction of the slurry, fracture of the water-stop ring weld, poor sealing effect, etc., and achieves simple installation. , not easy to dislocate, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

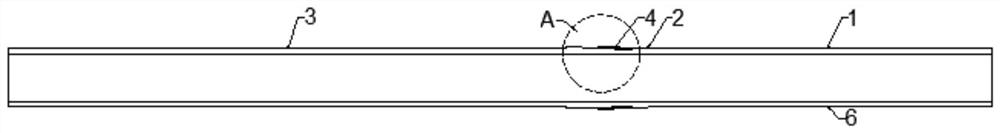

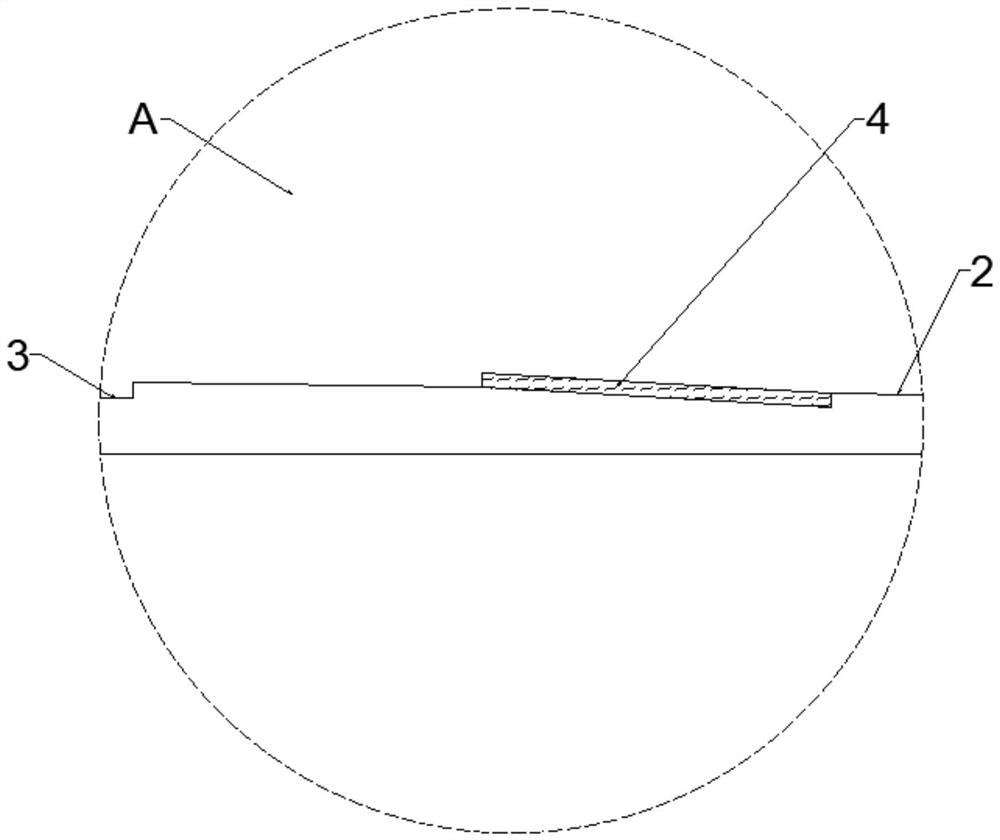

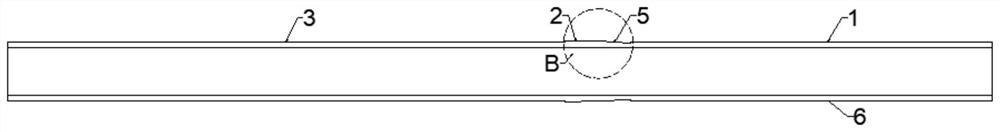

[0038]In this embodiment, the water stop device used to prevent water leakage through the through hole is as follows: figure 1 and figure 2 As shown, it includes a water-tight water-stop body 6 and a water-sealing rubber ring 4; One section; along the outer surface of the self-tightening water-stop section 2 of the water-leakage water-stop body 6, a card groove 5 is provided in the circumferential direction, and the water-sealing rubber ring 4 is set on the water-leakage water-stop body 6 through the card groove 5, and the water-leakage water-stop body 6 One end is detachably and fixedly connected with the drill bit, and the other end is detachably and hermetically fixedly connected with the freezing tube. The length of the water leakage and water stop body 6 is 1.5m, and the inner diameter is 73mm.

[0039] Such as Figure 5 As shown, the leakage and water-stop body 6 is composed of the drill bit connection section 1, the self-tightening water-stop section 2 and the freez...

Embodiment 2

[0044] The processing method of the water stop device for preventing through-hole water leakage in embodiment 1 comprises the following steps:

[0045] Step A: Take a 95*11mm seamless steel pipe with a length of 1.5m, and use a lathe to process the seamless steel pipe into a leaky waterstop body 6, so that the leaky waterstop body 6 is a self-tightening waterstop section with thick ends and thin ends. Seam steel pipe, that is, use a lathe to process the outer diameter of the seamless steel pipe at a distance of 0-0.5m from the first end to 89mm, and at the same time process the inner diameter according to the size of the check valve and the drill bit and turn the thread to complete the drill bit connection section 1 processing; then the outer diameter of the seamless steel pipe 0.5-0.65m from the first end is processed into a self-tightening water-stop section 2 with a diameter increasing from 89mm to 93.5mm; then the remaining part of the seamless steel pipe is The outer diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com