Method for preparing ITO (Indium Tin Oxide) film based on magnetron sputtering and etching treatment

A magnetron sputtering and thin film technology, applied in the field of preparing ITO thin films based on magnetron sputtering and etching treatment, to achieve the effects of reducing environmental pollution, stable sputtering environment and single phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

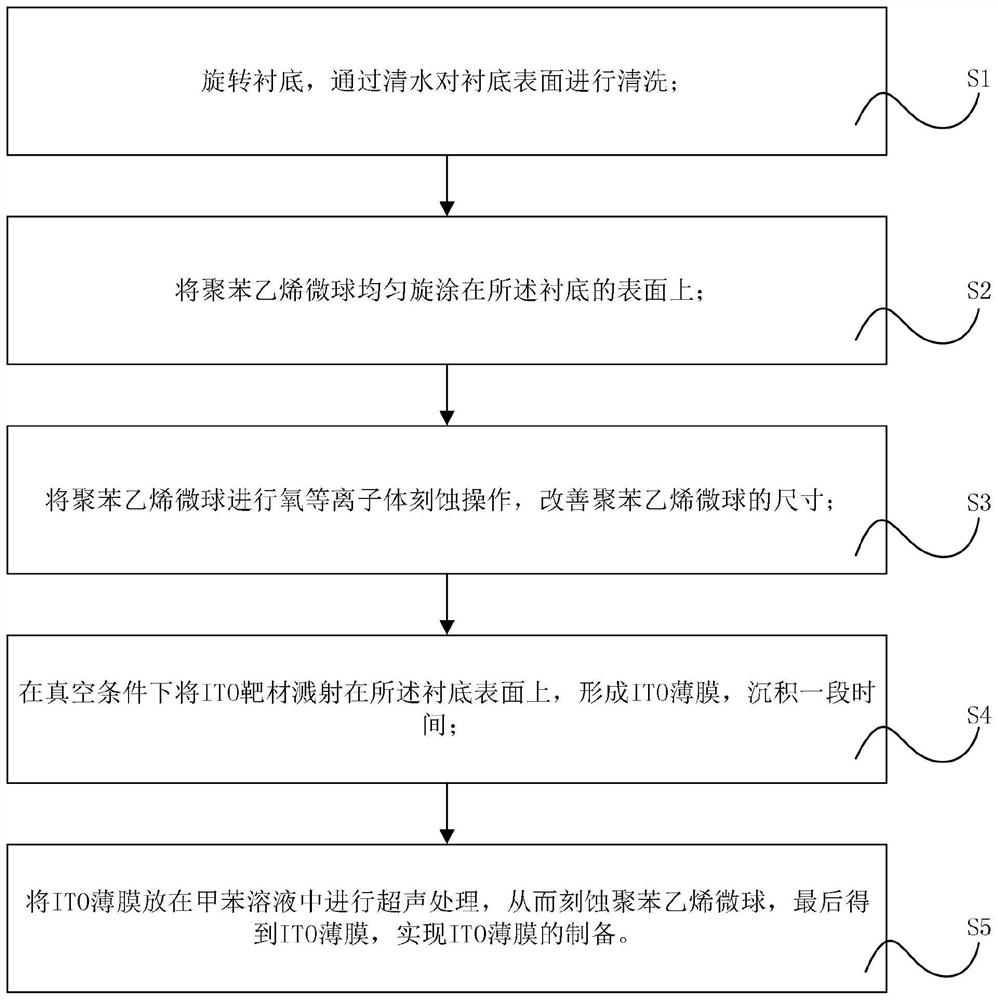

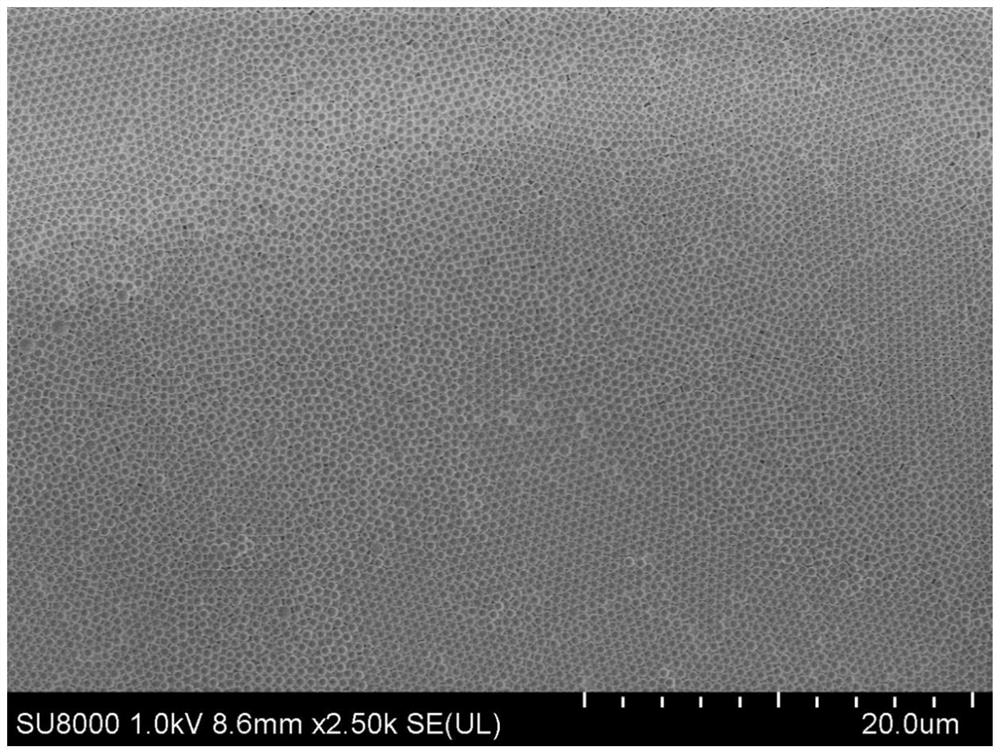

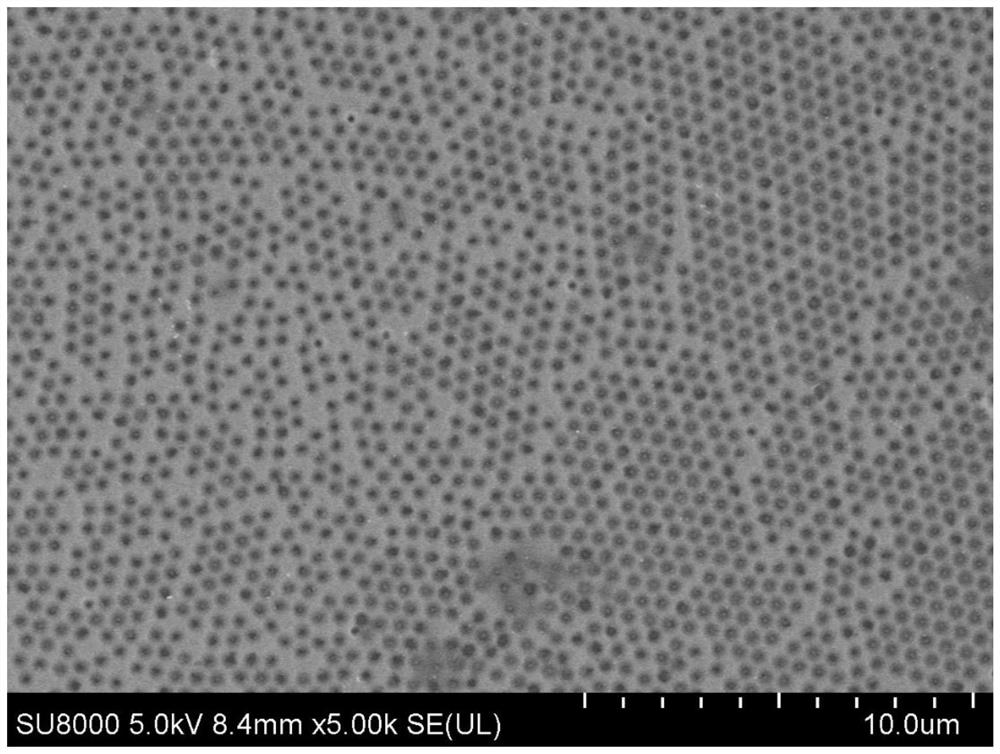

[0039] Example 1 (see figure 2 shown)

[0040] 1. Clean the glass substrate first: immerse the glass substrate in detergent, deionized water, ethanol, and acetone solution in sequence, then clean it in a plasma cleaner, and dry it with nitrogen;

[0041] 2. Place the cleaned glass substrate on a spin coater, and spin coat PS pellets with a mass fraction of 10ωt% on the glass substrate at 2500r / min for 15s;

[0042] 3. Place the above-mentioned substrate spin-coated with a layer of PS spheres in a plasma etching device, and etch for 2 minutes with a power of 60w;

[0043] 4. Place the processed substrate in the magnetron sputtering studio, use the magnetron sputtering coating system, and pump the background vacuum of the sputtering system to less than 5.0pa;

[0044] 5. Sputtering gas Ar bombards the target through the magnetron sputtering coating machine,

[0045] The sputtering gas uses argon with a purity of 99.9%;

[0046] The target material is an ITO target with a pu...

Embodiment 2

[0052] 1. Clean the glass substrate first: immerse the glass substrate in detergent, deionized water, ethanol, and acetone solution in sequence, then clean it in a plasma cleaner, and dry it with nitrogen;

[0053] 2. Place the cleaned glass substrate on a spin coater, and spin coat PS pellets with a mass fraction of 10ωt% on the glass substrate at 2500r / min for 15s;

[0054] 3. Place the above-mentioned substrate spin-coated with a layer of PS spheres in a plasma etching device, and etch for 1 min with a power of 60w;

[0055] 4. Place the processed substrate in the magnetron sputtering studio, use the magnetron sputtering coating system, and pump the background vacuum of the sputtering system to less than 5.0pa;

[0056] 5. Sputtering gas Ar bombards the target through the magnetron sputtering coating machine,

[0057] The sputtering gas uses argon with a purity of 99.9%;

[0058] The target material is an ITO target with a purity of 99.8%;

[0059] The working air pressu...

Embodiment 3

[0063] 1. Clean the glass substrate first: immerse the glass substrate in detergent, deionized water, ethanol, and acetone solution in sequence, then clean it in a plasma cleaner, and dry it with nitrogen;

[0064] 2. Place the cleaned glass substrate on a spin coater, and spin coat PS pellets with a mass fraction of 10ωt% on the glass substrate at 2500r / min for 15s;

[0065] 3. Place the above-mentioned substrate spin-coated with a layer of PS beads in the plasma etching equipment, and etch for 3 minutes with a power of 60w;

[0066] 4. Place the processed substrate in the magnetron sputtering studio, use the magnetron sputtering coating system, and pump the background vacuum of the sputtering system to less than 5.0pa;

[0067] 5. Sputtering gas Ar bombards the target through the magnetron sputtering coating machine,

[0068] The sputtering gas uses argon with a purity of 99.9%;

[0069] The target material is an ITO target with a purity of 99.8%;

[0070] The working air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com