Method for improving surface quality of large-thickness steel plate produced by roller type quenching furnace

A technology of surface quality and quenching furnace, which is applied in the field of iron and steel metallurgy, can solve problems affecting the surface quality of steel plates, steel plate roll marks, and steel sheet single weight, etc., to achieve the effect of reducing roll mark defects, reducing surface corrosion, and reducing single weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

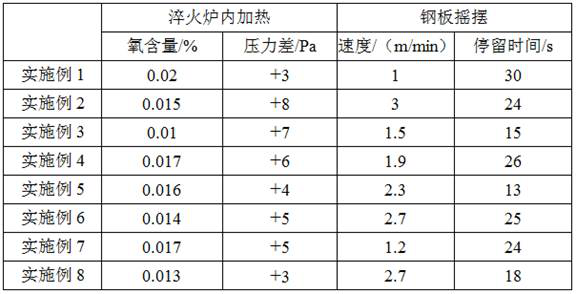

[0016] In Examples 1-8, before the steel plate enters the roller quenching furnace, the lower surface of the steel plate is mechanically ground and both sides of the steel plate are cut, the oxygen content in the quenching furnace is reduced and the slight positive pressure in the furnace is ensured, and the swing speed of the steel plate is strictly controlled during the swinging process in the furnace And reduce the swing residence time, when the steel plate goes in and out for quenching, the steel plate is blown with high-pressure air.

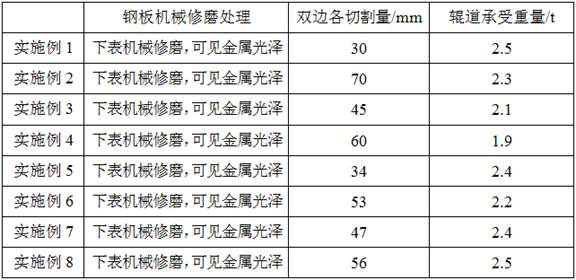

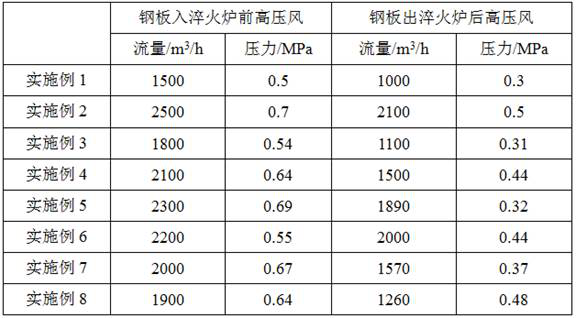

[0017] See Table 1 for the surface treatment of the steel plate before entering the furnace, the cutting sides and the bearing weight of the roller table. During the heating process of the steel plate quenching furnace, see Table 2 for the furnace atmosphere, pressure, steel plate swing speed and swing residence time. Before the steel plate enters the quenching machine and quenching See Table 3 for the flow rate and pressure of the high-pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com