Intelligent novel dry-process cement production line and method thereof

A dry-process cement and production line technology, which is applied in the field of cement production, can solve the problems of uneven heating of raw materials, low drying efficiency of raw materials, chaotic movement of raw materials, etc., and achieve diversified mixing methods, good crushing effect, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

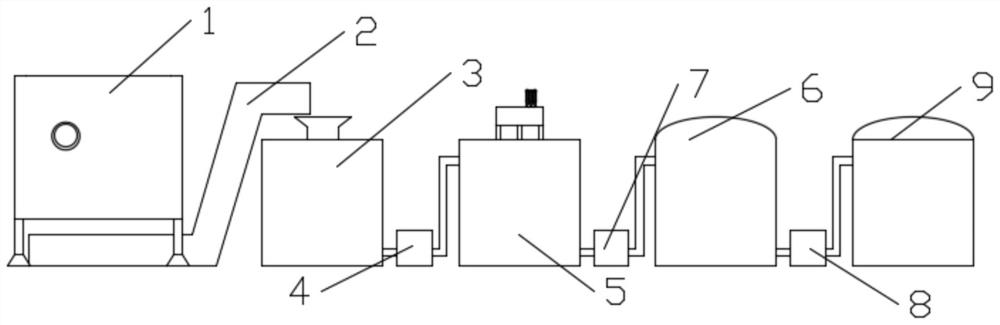

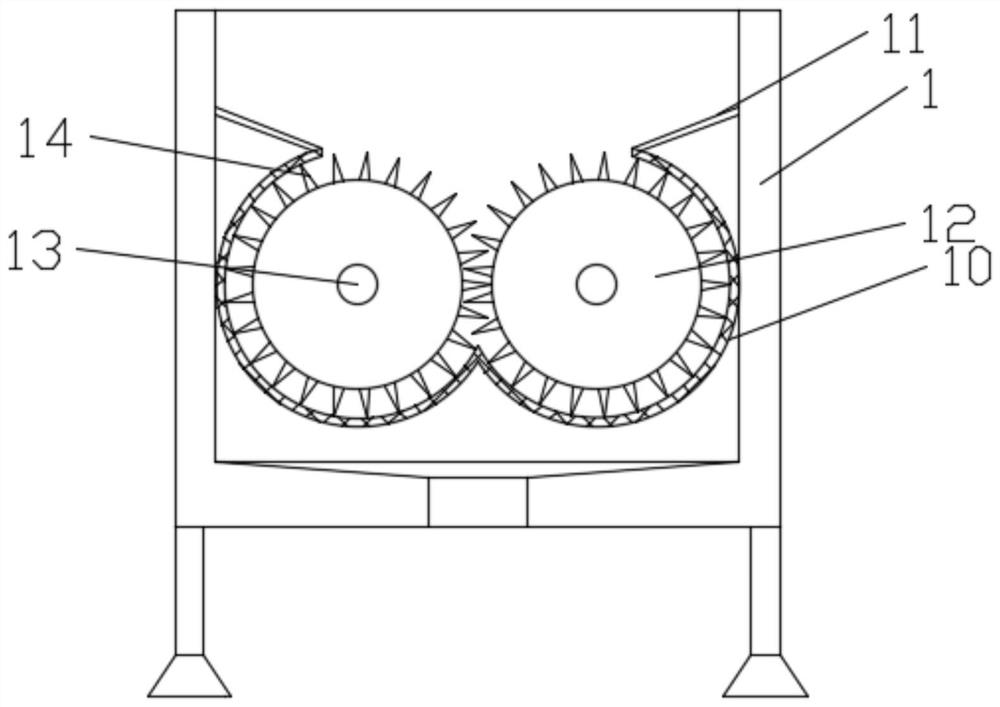

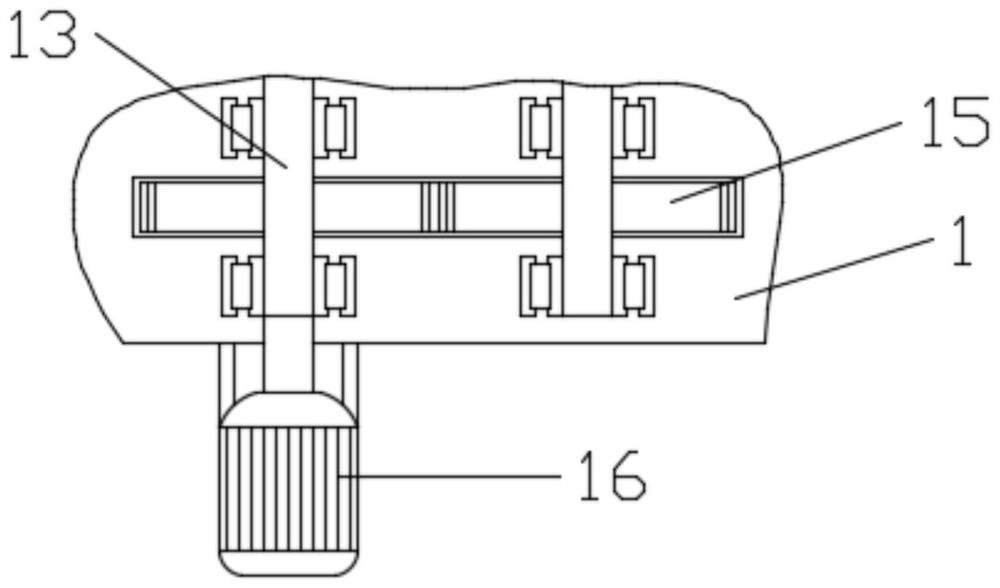

[0033] Refer to attached Figure 1-6 , the intelligent new dry-process cement production line provided by the present invention comprises a crushing box 1, a conveyor 2 and a pulverizer 3, the pulverizer 3 is connected with a drying box 5 through a first vacuum feeder 4, and the drying box 5 The air homogenization box 6 is connected through the second vacuum feeder 7, and the air homogenization box 6 is connected with the calcining kiln 9 through the third vacuum feeder 8, and also includes an installation block 28, a sieve material assembly, a crushing assembly, and a stirring mechanism And the drive assembly, the sieve material assembly and the crushing assembly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com