Ocean sump oil separation treatment device for environmental protection engineering

A technology of separation treatment and environmental protection engineering, applied in seawater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of oil solidification and stability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

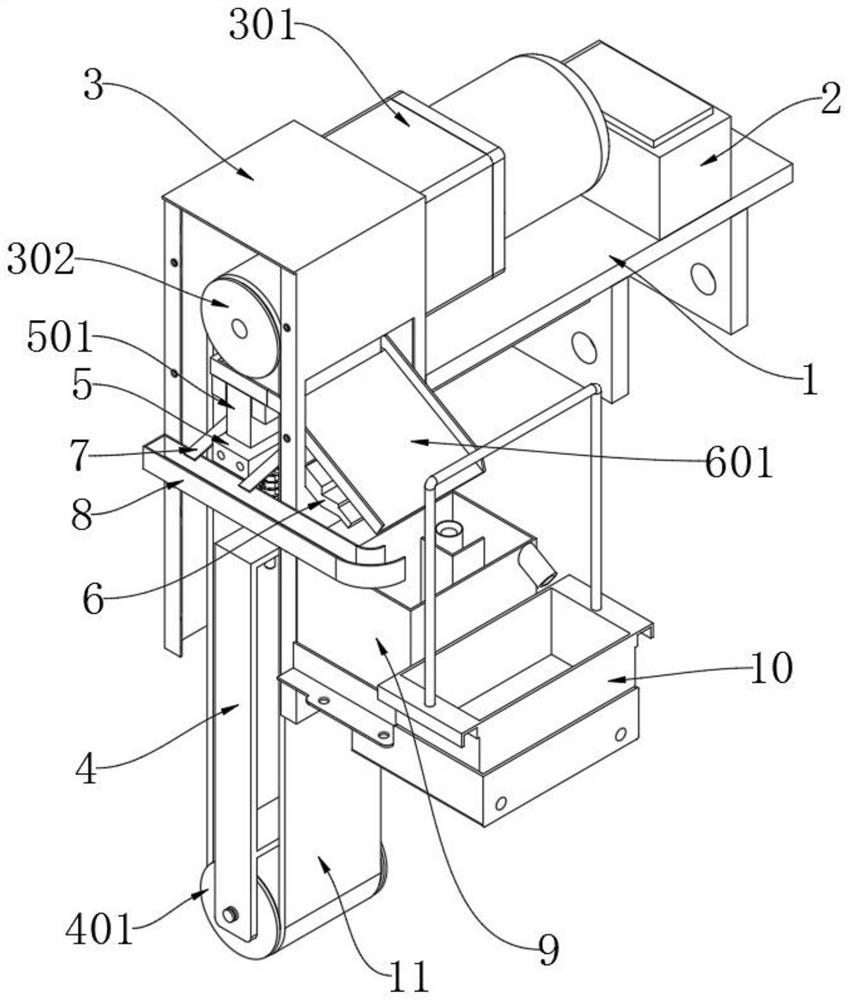

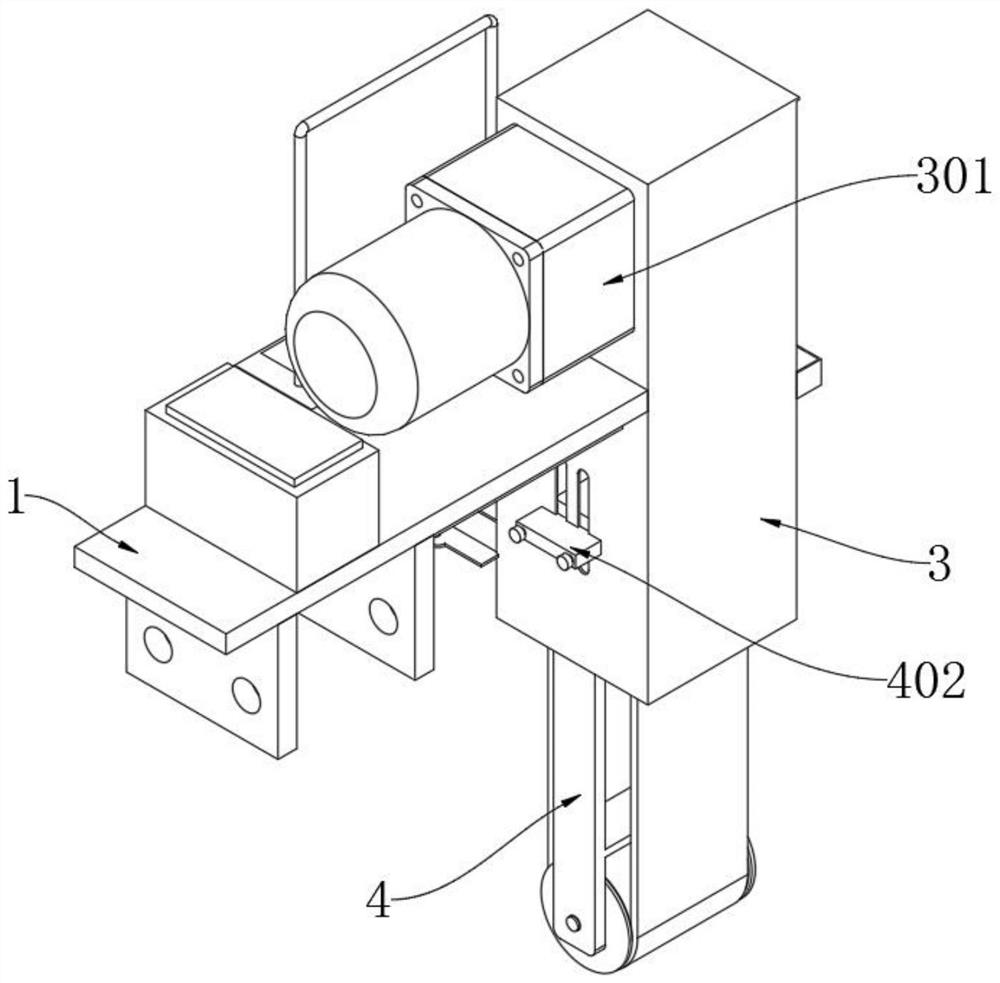

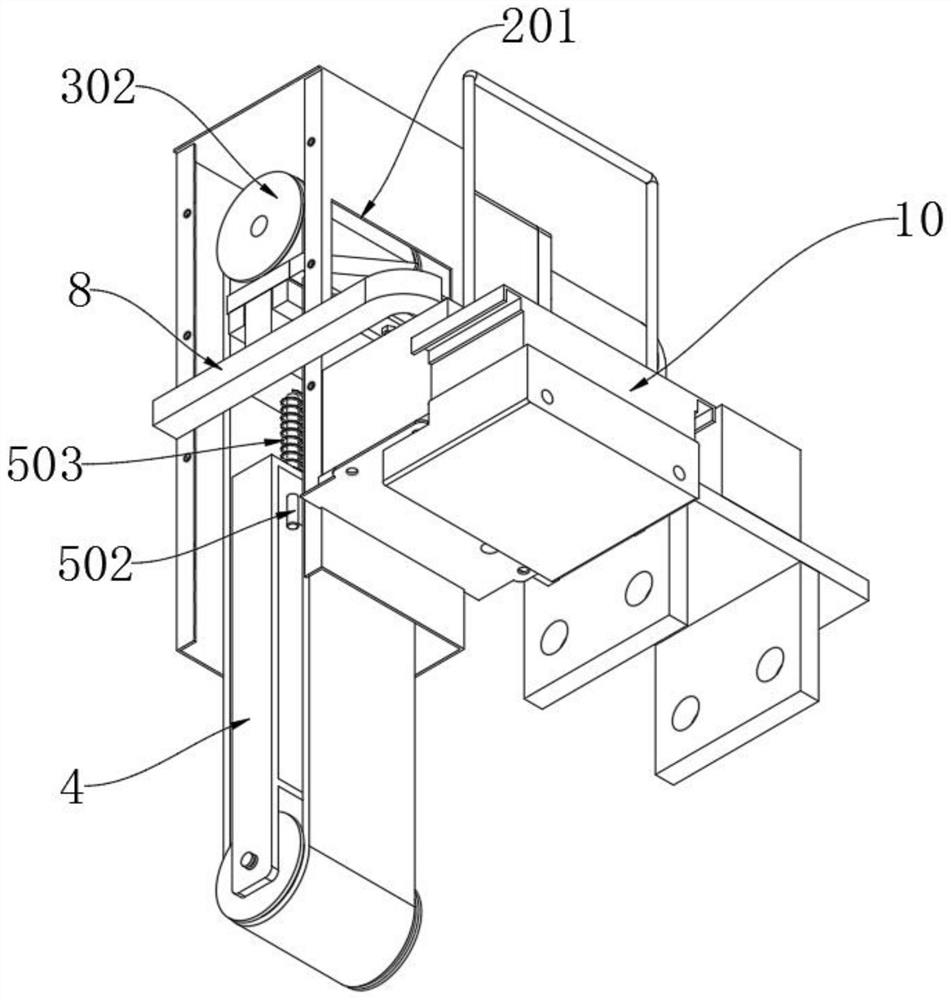

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a marine sewage oil separation treatment device for environmental protection engineering, comprising a mounting hanger 1; two clamping plates at the lower end of the mounting hanger 1 are installed in the hull; The upper end; the salvage frame 3 is vertically fixedly installed on the outer end of the hanger 1; the rear end side plate of the salvage frame 3 is equipped with a motor 301, and the rotating shaft of the motor 301 passes through the salvage frame 3 rear end side plate and is fixed with the drive roller 302 The lower end of the fishing frame 3 is vertically fixedly equipped with a driven bracket 4; the lower end of the driven bracket 4 is longitudinally rotatably equipped with a driven roller 401; connection; the upper end of the driven support 4 is vertically slidably equipped with a heating buffer frame 5; the scraper frame 6 is fixedly installed at the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com