High-energy-density lithium iron phosphate and preparation method thereof

A high energy density, lithium iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, lithium batteries, etc., can solve problems such as unfavorable production expansion, large polarization cannot be maintained, and capacity loss aggravated, to facilitate automated production. , Controllable particle size gradation, and the effect of improving energy density

Active Publication Date: 2022-04-12

常州锂源新能源科技有限公司

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007]

In view of the above-mentioned related technologies, the inventor believes that the lithium iron phosphate battery is charged and discharged at a high rate, the capacity loss is aggravated, and the polarization is large and cannot maintain a high energy density.

In order to improve the gram capacity of the material, the manufacturer reduces the particle size of the sand mill, resulting in excessive viscosity of the slurry during the fine grinding process, resulting in tank blockage, which is not conducive to production expansion, and the decrease in the compaction density of the material when the particle size of the sand mill becomes larger also causes loss of energy density

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example 1

[0042] Get 400kg graphene as carbon source 1.

preparation example 2

[0044] Take 100kg of glucose as carbon source 2.

preparation example 3

[0046] Take 50kg graphene and 50kg glucose and mix them as carbon source 3.

[0047] It is worth noting that the carbon source includes, but is not limited to, any one or a combination of graphene, carbon nanotubes, glucose, sucrose, starch, maltose, and polyethylene glycol.

[0048] Preparation of doping elements

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

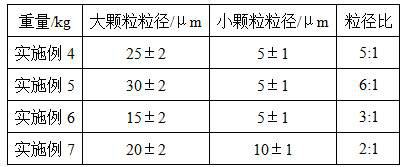

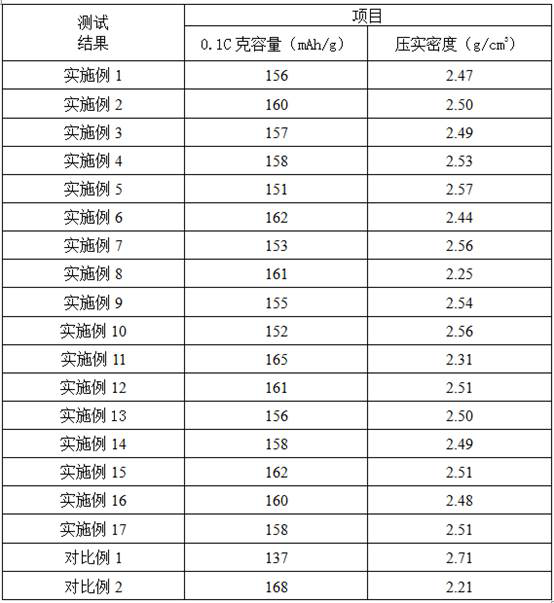

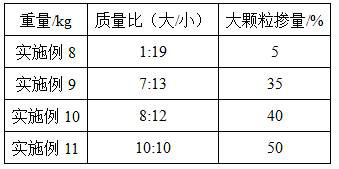

The invention relates to the technical field of lithium batteries, and particularly discloses high-energy-density lithium iron phosphate and a preparation method thereof. The high-energy-density lithium iron phosphate comprises at least one large-particle lithium iron phosphate and at least one small-particle lithium iron phosphate, the mass ratio of the large-particle lithium iron phosphate to the small-particle lithium iron phosphate is (1-10): (10-19), and the particle size ratio of the large-particle lithium iron phosphate to the small-particle lithium iron phosphate is (2-6): 1. The invention discloses a preparation method of high-energy-density lithium iron phosphate. The preparation method comprises the following steps: S1, preparing lithium iron phosphate slurry; s2, preparing a lithium iron phosphate precursor; and S3, preparing the lithium iron phosphate. The high-energy-density lithium iron phosphate disclosed by the invention has relatively high energy density and high compaction density; and the preparation method disclosed by the invention has the characteristics of simple synthesis process, controllable particle size grading, uniform material mixing and the like.

Description

technical field [0001] The application relates to the technical field of lithium batteries, and specifically discloses a high-energy-density lithium iron phosphate and a preparation method thereof. Background technique [0002] The market demand for lithium iron phosphate mainly lies in the field of power batteries and energy storage. In recent years, the proportion of lithium iron phosphate power batteries in new energy vehicles has increased year by year and has remained stable at more than 90%. With continuous improvement, the research and development of lithium iron phosphate materials with high energy density has become an inevitable choice for enterprise development. [0003] At present, the technological development trend of global lithium iron phosphate research and development is relatively obvious, mainly divided into the following three directions: [0004] ① Improve compaction density: Improve the compaction density of lithium iron phosphate materials by refinin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B25/45H01M4/36H01M4/58H01M10/052

CPCY02E60/10

Inventor 孙丽媛袁超石俊峰

Owner 常州锂源新能源科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com