Ton bag production method

A production method and technology for ton bags, which are applied in the directions of stretch spinning, weaving, containers, etc., can solve the problems of poor flatness, insufficient tensile strength, and poor drop performance of ton bags, so as to reduce manpower and improve tensile strength. And the effect of flatness and strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

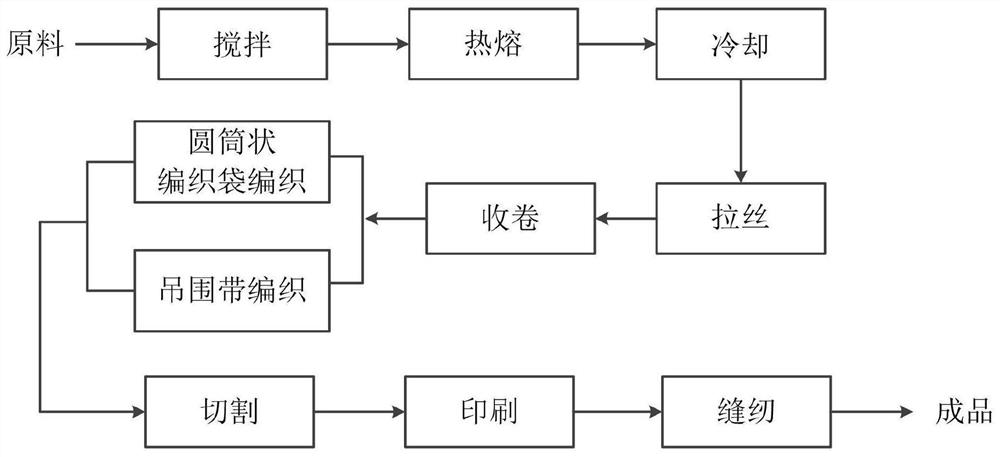

Method used

Image

Examples

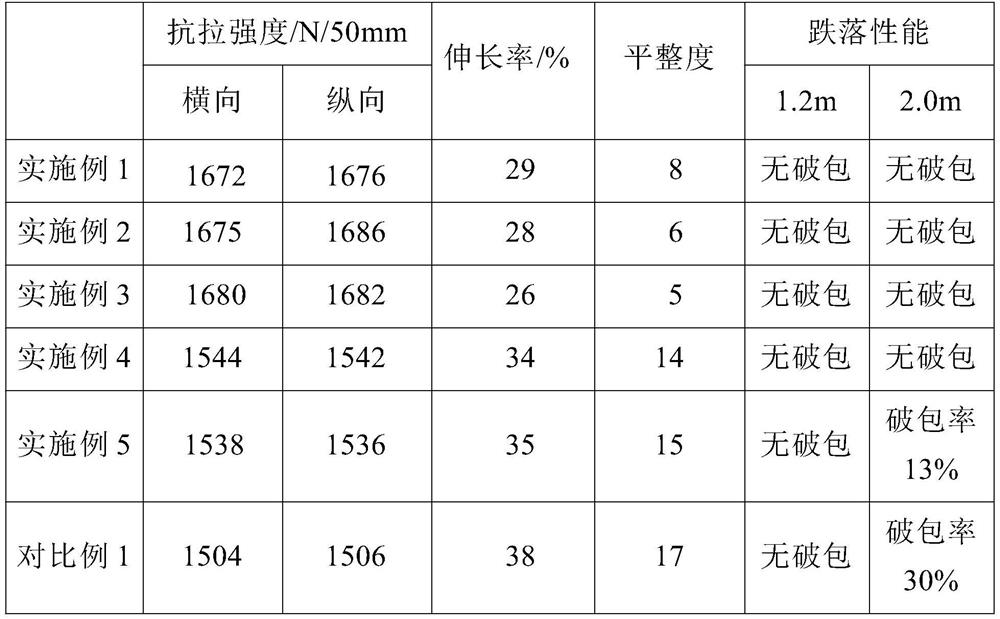

Embodiment 1

[0070] The production method of the big bag in the present embodiment is carried out according to the following steps:

[0071] (1) Stirring: mix the raw material and the filler masterbatch according to the weight ratio of 9:1, and stir evenly to obtain the mixed raw material. The filler masterbatch includes the following components:

[0072] 80 parts by weight of calcium carbonate;

[0073] 5 parts by weight of dispersant, dispersant is made up of paraffin wax and fatty acid polyethylene glycol ester with the ratio of weight ratio 1:0.5;

[0074] 6 parts by weight of plasticizer, plasticizer is made up of dioctyl phthalate and glycol fatty acid ester with the ratio of 1:2 by weight;

[0075] 2 parts by weight of masterbatch;

[0076] 3 parts by weight of the reinforcing agent, the reinforcing agent is composed of cyanoethyl cellulose and ethopabate in a weight ratio of 1:1.

[0077] (2) Hot-melt: heat the mixed raw materials to 220°C for hot-melt to a viscous fluid state,...

Embodiment 2

[0086] The production method of the big bag in the present embodiment is carried out according to the following steps:

[0087] The only difference from Example 1 is:

[0088](1) Stirring: mix the raw material and the filler masterbatch according to the weight ratio of 15:1, and stir evenly to obtain the mixed raw material. The filler masterbatch includes the following components:

[0089] 85 parts by weight of calcium carbonate;

[0090] 6 parts by weight of dispersant, dispersant is made up of paraffin wax and fatty acid polyethylene glycol ester with the ratio of 1:1 by weight;

[0091] 7 parts by weight of plasticizer, plasticizer is made up of dioctyl phthalate and glycol fatty acid ester with the ratio of 1:1 by weight;

[0092] 4 parts by weight of masterbatch;

[0093] 5 parts by weight of the reinforcing agent, the reinforcing agent is composed of cyanoethyl cellulose and ethopabate with a weight ratio of 1:2.

[0094] (2) Hot melt: heat the mixed raw materials t...

Embodiment 3

[0099] The production method of the big bag in the present embodiment is carried out according to the following steps:

[0100] The only difference from Example 1 is:

[0101] (1) Stirring: mix the raw material and the filler masterbatch according to the weight ratio of 19:1, and stir evenly to obtain the mixed raw material. The filler masterbatch includes the following components:

[0102] 90 parts by weight of calcium carbonate;

[0103] 7 parts by weight of dispersing agent, dispersing agent is made up of paraffin wax and fatty acid polyethylene glycol ester with the ratio of weight ratio 1:1.5;

[0104] 7 parts by weight of plasticizer, plasticizer is made up of dioctyl phthalate and glycol fatty acid ester with the ratio of 2:1 by weight;

[0105] 5 parts by weight of masterbatch;

[0106] 6 parts by weight of the reinforcing agent, the reinforcing agent is composed of cyanoethyl cellulose and ethopabate with a weight ratio of 1:0.5.

[0107] (2) Hot-melt: Heat the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com