Bamboo green and yellow separation equipment and separation method thereof

A technology for separating equipment and bamboo bodies, which is applied in mechanical equipment, sugarcane machining, forming/shaping machines, etc., can solve the problems of difficult separation of bamboo green and bamboo yellow, low bamboo utilization rate, and poor separation accuracy, and achieve The effect of high adjustment efficiency, improved utilization rate and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

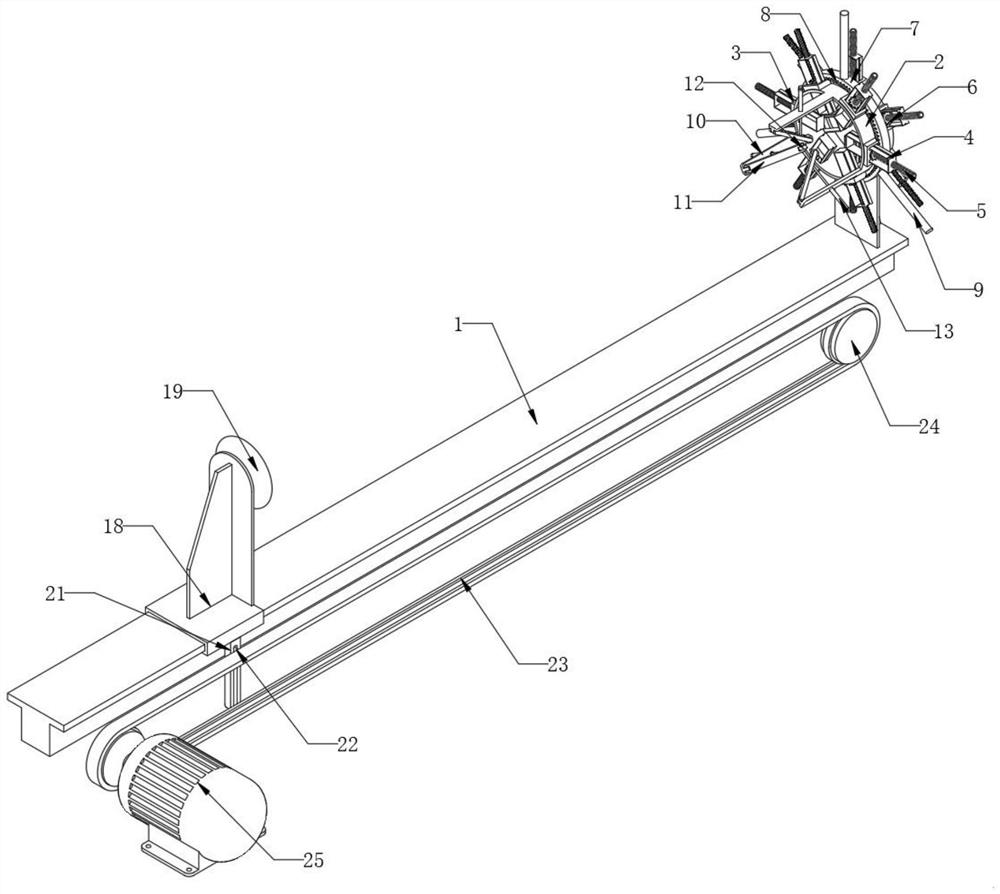

[0038] see Figure 1-7 Shown, a kind of bamboo green and yellow separation equipment comprises guide rail 1, and the edge place of guide rail 1 upper side is fixedly connected with annular holder 2, and ring holder 2 is provided with a plurality of cutting blades 4, and one of cutting blades 4 The side is a knife edge, and a knife adjustment mechanism is also provided on the annular fixed frame 2 to adjust the positions of a plurality of cutting blades 4;

[0039] At this time, when the bamboo moves towards the direction close to the cutting blade 4, the cutting blade 4 will cut the green bamboo outside the bamboo.

[0040] Among them, see figure 1 with Figure 4-5 As shown, in order to allow the cutting blades 4 to cut bamboos of different sizes and avoid gaps between two adjacent cutting blades 4, the plurality of cutting blades 4 are divided into two groups, and the two groups of cutting blades 4 are all annular In the array, at the same time, two sets of cutting blades ...

Embodiment 2

[0056] Disclose a kind of bamboo green yellow separation method on the basis of embodiment 1, be the using method of a kind of bamboo green yellow separation equipment, method comprises the following steps:

[0057] The first step: Turn the toggle lever 9 to drive the transmission ring 7 to rotate on the outside of the ring holder 2. When the transmission ring 7 rotates, it will drive the bevel gear 6 to rotate together through the transmission bevel gear ring 8. When the bevel gear 6 rotates, it will Drive the threaded rod 5 to rotate together, because the threaded rod 5 is threadedly connected with the cutting blade 4, the cutting blade 4 can be driven to move by rotating the threaded rod 5, and the length of the cutting blade 4 stretched into the ring holder 2 can be adjusted, so that different sizes bamboo for cutting;

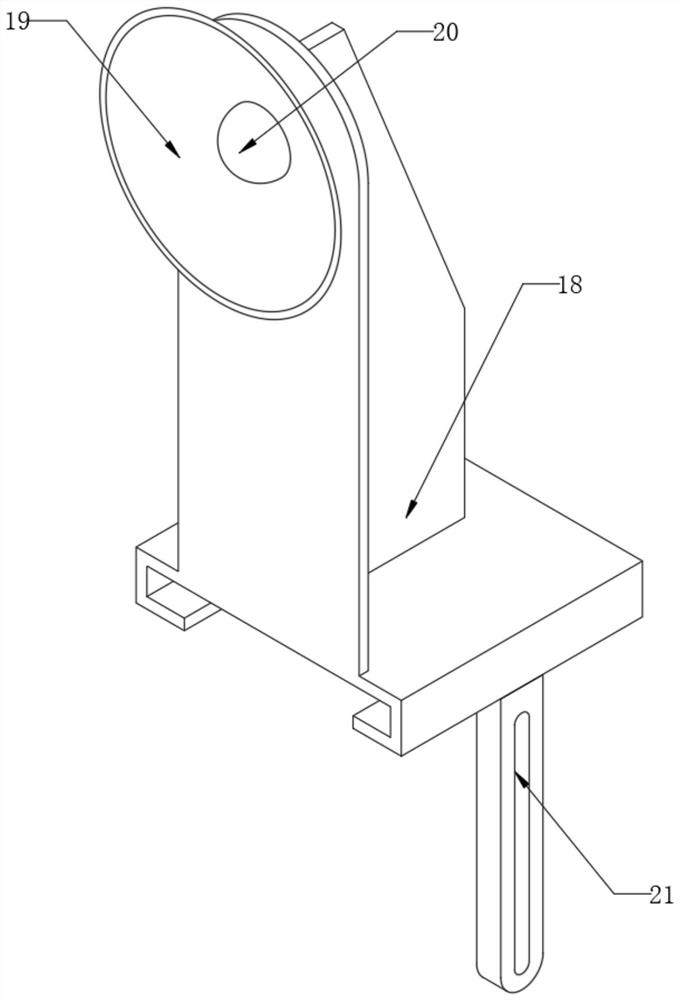

[0058] Second step: the bamboo is placed between the bamboo body transmission mechanism and the ring fixing frame 2, and the two ends of the bamboo are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com