Polishing pad, manufacturing method of polishing pad, and manufacturing method of semiconductor device

A manufacturing method and technology of polishing pads, which are applied in the field of polishing pads, can solve the problems such as the increase of concaves on the surface of semiconductor wafers, and achieve the effect of preventing defects and increasing the area of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0215] Manufacturing of Polishing Pads

[0216] Toluene diisocyanate (TDI), dicyclohexylmethane diisocyanate (H 12 MDI), polytetramethylene ether glycol (Polytetramethylene ether glycol) and diethylene glycol (Diethylene glycol) were put into a four-necked flask, and reacted at 80°C for 3 hours to prepare a preform with an NCO% of 8 to 12%. Polymer (Prepolymer).

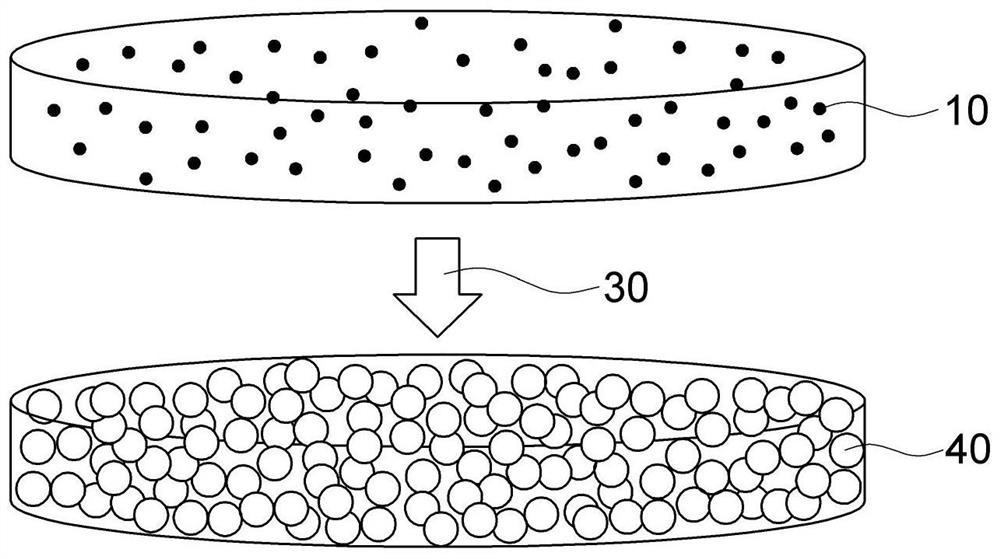

[0217] In order to manufacture the polishing layer (Top Pad), in the casting machine (Casting Machine) equipped with prepolymer (Prepolymer), curing agent, inert gas injection pipeline and liquid phase foaming agent injection pipeline, the prepared prepolymer (Prepolymer) is filled in the prepolymer tank (Prepolymer Tank), and the curing agent tank is filled with bis (4-amino-3-chlorophenyl) methane (Bis (4-amino-3-chlorophenyl) methane) (Ishihara (Ishihara) company), while preparing nitrogen (N 2 ) was used as an inert gas, and FC3283 (3M company) was prepared as a liquid-phase blowing agent. Unexpanded solid bl...

Embodiment 2

[0223] It was produced in the same manner as in Example 1, except that unexpanded 031DU40 from AkzoNobel was used as the solid-phase blowing agent. The shell (Shell) component of the solid phase foaming agent is polyvinylidene chloride (Polyvinylidene chloride) or acrylonitrile (Acrylonitrile).

Embodiment 3

[0233] Manufacturing of Polishing Pads

[0234] The TDI, H 12 After MDI, polytetramethylene ether glycol (Polytetramethylene ether glycol) and diethylene glycol (Diethylene glycol) were put into a four-necked flask, they were reacted at 80°C for 3 hours to prepare a prepolymer with an NCO% of 8 to 12%. Material (Prepolymer).

[0235] In order to manufacture the polishing layer (Top Pad), in the casting machine (Casting Machine) equipped with prepolymer, curing agent, inert gas injection pipeline and liquid phase foaming agent injection pipeline, fill the prepared prepolymer into the pre polymer tank, and fill bis(4-amino-3-chlorophenyl)methane (Bis(4-amino-3-chlorophenyl)methane) (Ishihara Company) in the curing agent tank, and prepare nitrogen (N 2 ) was used as an inert gas, and FC3283 (3M company) was prepared as a liquid-phase blowing agent.

[0236] The solid-phase blowing agent (AkzoNobel, 551DU40) and the silicon-based surfactant (Evonik) were mixed into the prepolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com