Foaming sheet material for packaging

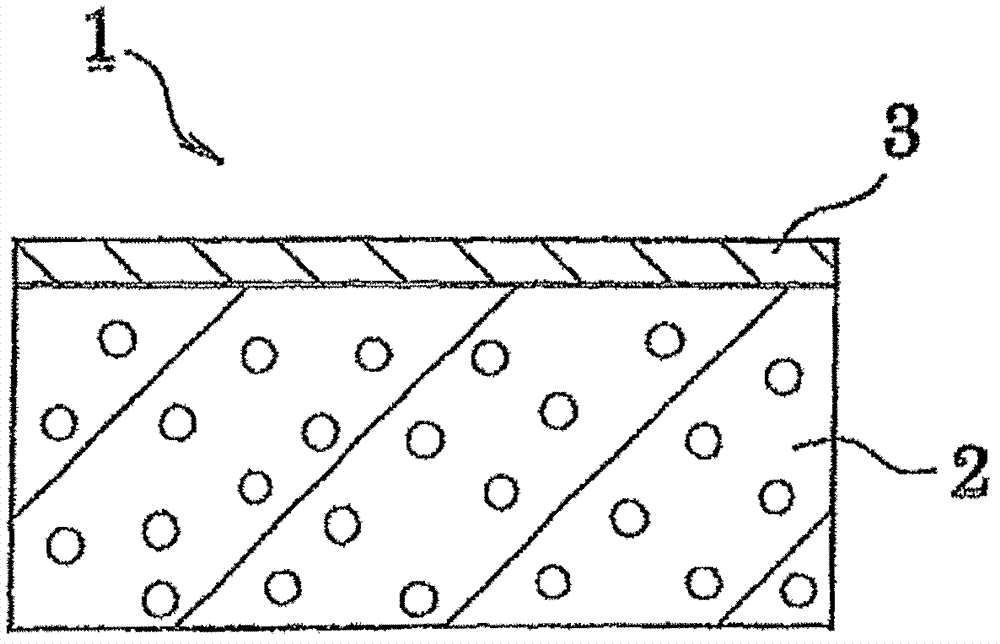

A technology for foam sheet and packaging, which is applied in the field of foam sheet for packaging, and can solve problems such as poor appearance, bad packaging materials, packing materials, damage to the appearance of packaged items, etc., and achieve excellent softness and cushioning , to prevent the effect of bad surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

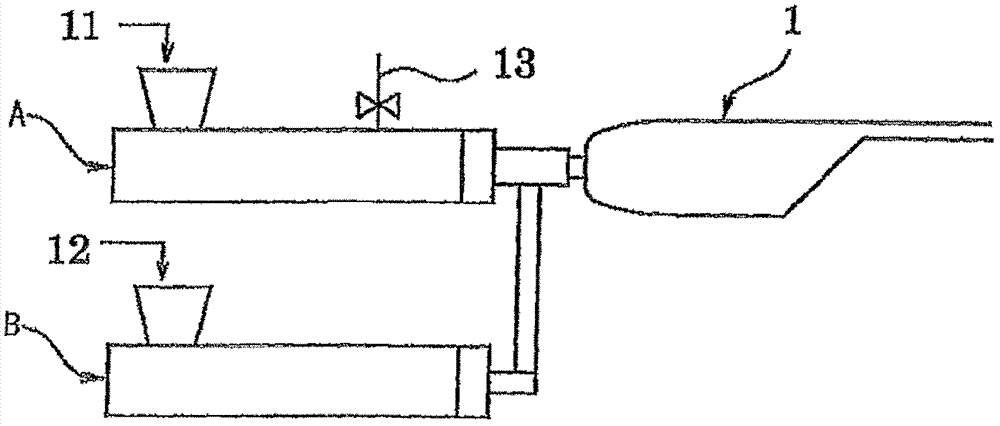

[0070] As the first extruder for forming the polyolefin-based resin foam layer, a tandem extruder in which an extruder with a diameter of 90 mm and an extruder with a diameter of 120 mm were connected to each other was used as As the second extruder for forming the polyolefin-based resin layer, an extruder having a diameter of 50 mm and L / D=46 (L is length and D is diameter) was used. In addition, at the extruder outlets of the first extruder and the second extruder, an annular die with a diameter of 94 mm was used for coextrusion of the foamed sheet.

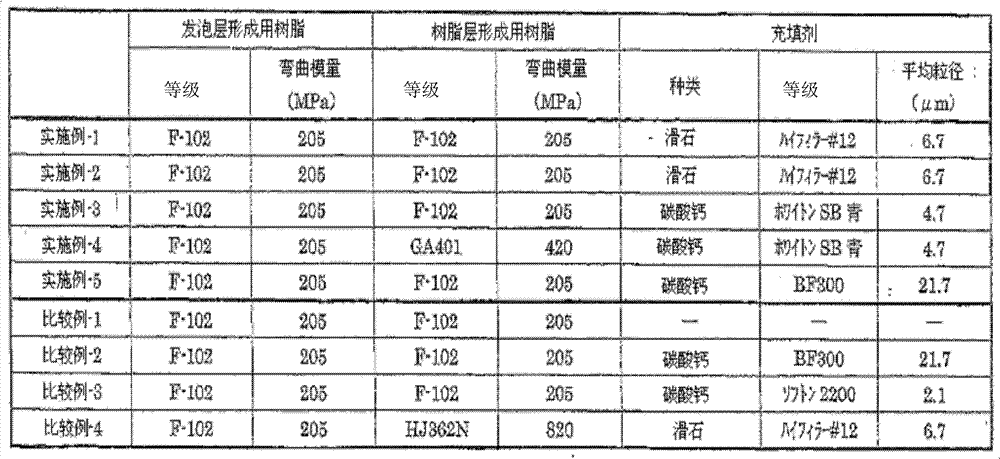

[0071] To form a polyolefin-based resin foam layer, compared to low-density polyethylene (flexural modulus: 205MPa, MFR (melt flow rate) = 0.4g / 10min, manufactured by Sumitomo Chemical: trade name "Sumikasen F-102") 100 parts by weight of 3 parts by weight of the cell regulator masterbatch was mixed, supplied to the raw material inlet of an extruder with a diameter of 90 mm, and heated and kneaded to prepare a molten resin mixt...

Embodiment 2

[0090] The thickness of the foamed sheet for packaging in Example 1 is set to 1.02 mm, and the basis weight of the resin layer is set to 0.9 g / m 2 , except that it was the same as in Example 1, thereby obtaining the foamed sheet for packaging of the present invention.

[0091] The apparent density of this packing foam sheet, thickness, the flexural modulus of the substrate resin of resin layer, the average particle diameter D of filler, basis weight B, average thickness, D / B are as shown in table 1 and table 2 Show.

Embodiment 3

[0093] The thickness of the foamed sheet for packaging in Example 1 was set to 1.08 mm, and calcium carbonate was used as a filler instead of talc (manufactured by Shiraishi Calcium Co., Ltd.: trade name "Howaiton SB Blue"; average particle size 4.7 μm) , set the basis weight of the resin layer to 0.9g / m 2 , except that it was the same as in Example 1, thereby obtaining the foamed sheet for packaging of the present invention.

[0094] The apparent density of this packing foam sheet, thickness, the flexural modulus of the substrate resin of resin layer, the average particle diameter D of filler, basis weight B, average thickness, D / B are as shown in table 1 and table 2 Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com