Acoustic micro-fluidic system for cell fusion as well as preparation method and application of acoustic micro-fluidic system

A microfluidic system and cell fusion technology, applied in the field of acoustic microfluidic system for cell fusion and its preparation, can solve the problems of limiting wide application, increasing cell damage, low fusion efficiency, etc., achieving simple operation and high repeatability , the effect of low heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

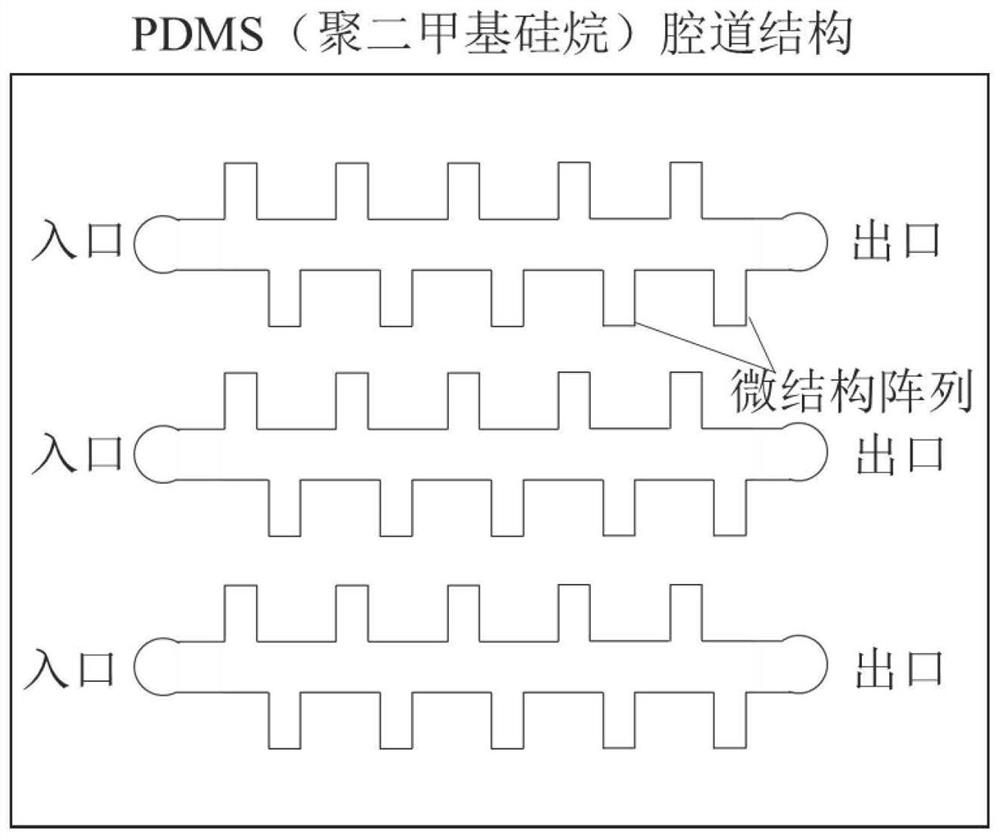

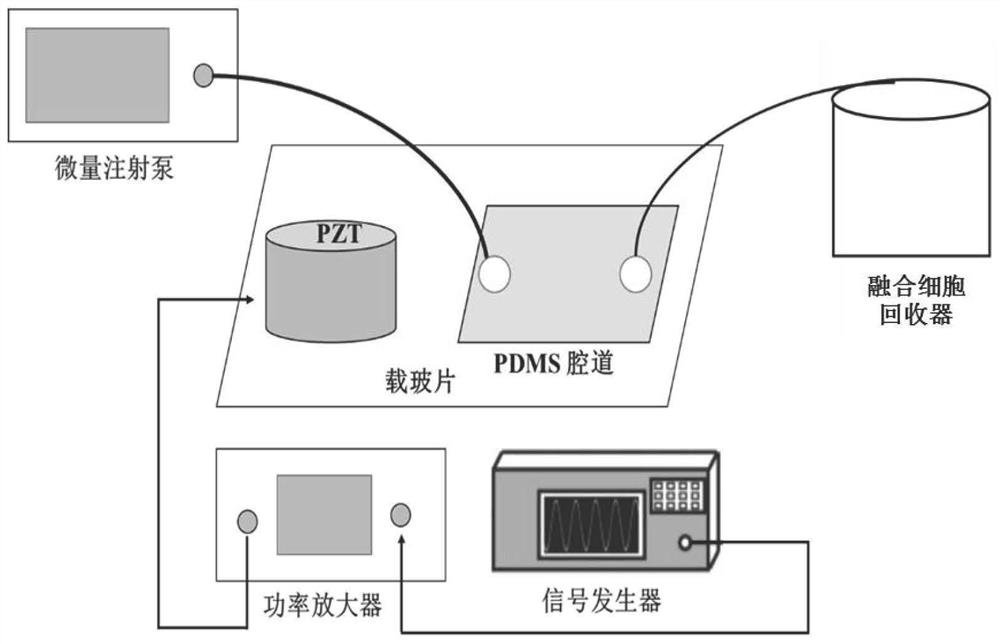

[0048] 1. PDMS cavity preparation and bonding

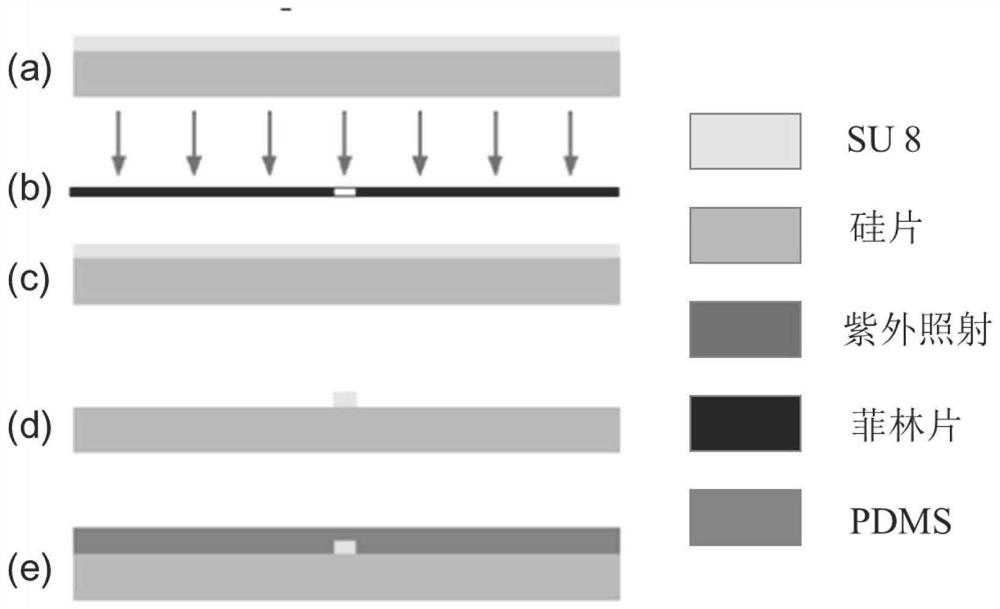

[0049] figure 1 (a-e) shows the fabrication process of PDMS.

[0050] (1) Pretreatment: Remove residual impurities on the surface of the silicon substrate, such as dust and organic adsorbents, by pickling, alcohol washing, and water washing, and finally place the silicon wafer in a clean place to dry.

[0051] (2) Coating and pre-baking: use a coating machine to spin-coat SU-8(50) negative photoresist, 3000rpm, 30s, the thickness of SU-8(50) is about 50μm. After coating, the silicon wafer was placed horizontally on a heating plate at 90°C for 1 hour to allow the solvent in the photoresist to evaporate, so as to enhance the adhesion between the photoresist and the silicon wafer, and obtain figure 1 The graph in (a).

[0052] (3) Exposure and development: take the film that has already made graphics such as figure 1 (b) placed in figure 1 In (a), the photoresist is exposed through an exposure machine, and the exposure dose is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com