Preparation method of Pinctada martensii Beta meat seasoning base material and product of Pinctada martensii Beta meat seasoning base material

A technology of mother-of-pearl shellfish and seasoning base material, which is applied in food science and other fields, can solve the problems of shellfish meat abandonment and waste of resources, and achieve the effect of simple processing method, rich essential amino acids, and improved product taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of Pinctada martensii shellfish seasoning base material, the steps are as follows:

[0036] 1. Add water to the fresh and clean Pinctada martensii meat at a ratio of 10:1 (W / V, g / mL), and grind it with a meat grinder to form a meat slurry;

[0037] 2. Add 80mL of citric acid aqueous solution with a mass concentration of 2‰ to 1g of meat slurry at a ratio of 10:1 (W / V, g / mL), and bathe in a water bath at 90°C for 20min;

[0038] 3. Place the meat slurry after the water bath in a centrifuge, centrifuge at a speed of 3000r / min and 4°C for 5 minutes, discard the centrifuged liquid, and collect the shellfish;

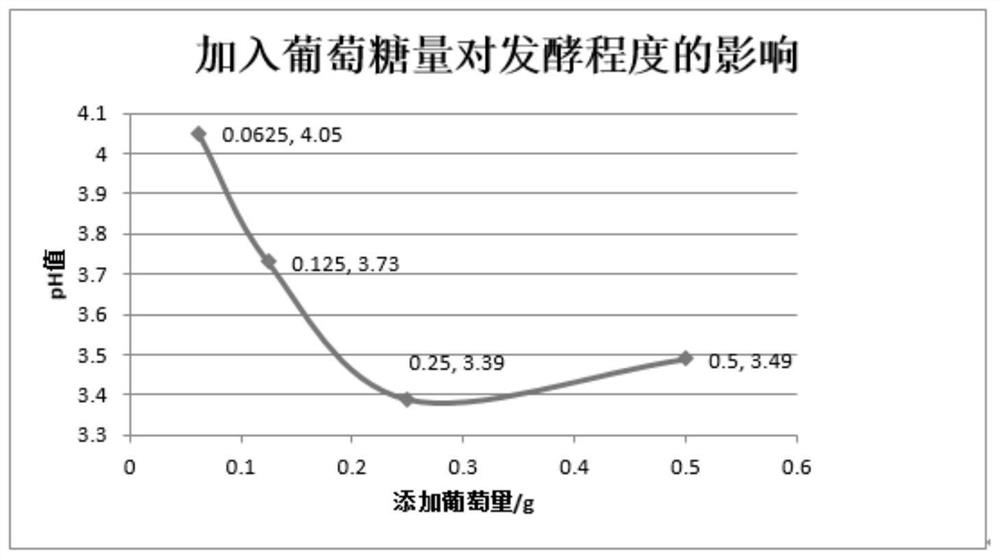

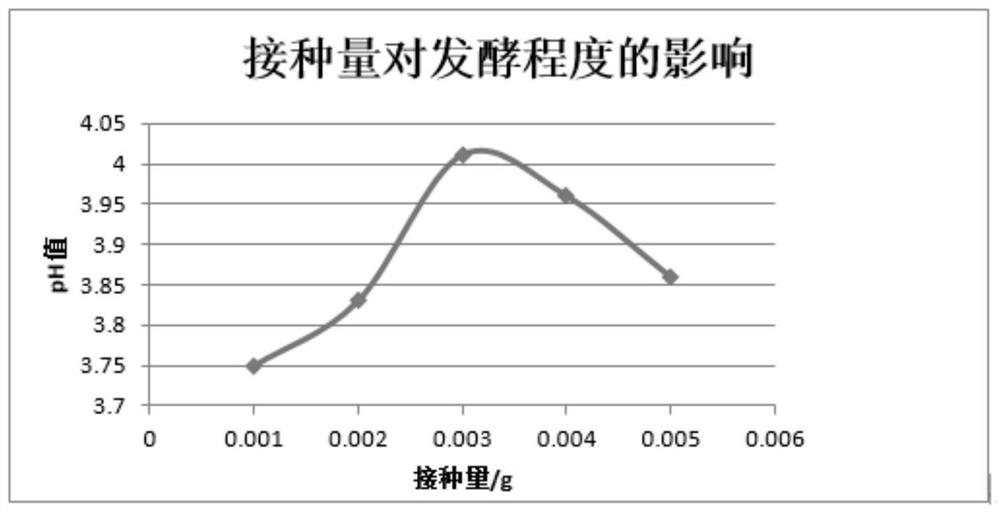

[0039] 4. Take 0.5g of centrifuged shellfish, add 5ml of water and 0.2g of glucose, inoculate lactic acid bacteria with 2‰ of centrifuged shellfish, and ferment in a biochemical incubator at 40°C for 28 hours. When the fermentation ends, the pH is 3.93;

[0040] 5. Freeze the fermented shellfish meat at -18°C for 12 hours, and then dry it into po...

Embodiment 2

[0042] 1. Add water to the fresh and clean Pinctada martensii meat at a ratio of 10:1 (W / V, g / mL), and grind it with a meat grinder to form a meat slurry;

[0043] 2. Add 80mL of acetic acid aqueous solution with a mass concentration of 2‰ to 1g of meat slurry at a ratio of 10:1 (W / V, g / mL), and bathe in a water bath at 90°C for 20min;

[0044] 3. Place the meat slurry after the water bath in a centrifuge, centrifuge at a speed of 3000r / min and 4°C for 5 minutes, discard the centrifuged liquid, and collect the shellfish;

[0045] 4. Take 0.5g of centrifuged shellfish, add 5ml of water and 0.2g of glucose, inoculate probiotics with 2‰ of centrifuged shellfish, and ferment in a biochemical incubator at 40°C for 28 hours. At the end of fermentation, pH=4.13;

[0046] 5. Freeze the fermented mussel meat at -18°C for 12 hours, and then dry it into powder in a vacuum freeze dryer at -50°C to obtain the Pinctada martensii with fishy smell, acetic acid smell and no meat fat smell. Me...

Embodiment 3

[0048] 1. Add water to the fresh and clean Pinctada martensii meat at a ratio of 10:1 (W / V, g / mL), and grind it with a meat grinder to form a meat slurry;

[0049] 2. Add 80mL of citric acid aqueous solution with a mass concentration of 2‰ to 1g of meat slurry at a ratio of 10:1 (W / V, g / mL), and bathe in a water bath at 90°C for 20min;

[0050] 3. Place the meat slurry after the water bath in a centrifuge, centrifuge at a speed of 3000r / min and 4°C for 5 minutes, discard the centrifuged liquid, and collect the shellfish;

[0051] 4. Take 0.5g of centrifuged shellfish, add 2ml of water, 0.15g of glucose, inoculate probiotics with 1.5‰ of centrifuged shellfish, and ferment in a biochemical incubator at 40°C for 24 hours. When the fermentation ends, pH=3.03;

[0052]5. Freeze the fermented shellfish meat at -18°C for 12 hours, and then dry it into powder in a vacuum freeze dryer at -50°C to obtain Marshmallow with no meat fat aroma, slight fishy smell, and obvious acetic acid sme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com