High-precision automatic seedling sowing device and method

A seed metering device and high-precision technology are applied in the field of high-precision automatic seedling metering devices and methods, and can solve the problems of low precision, low precision, and unqualified seeds for seeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

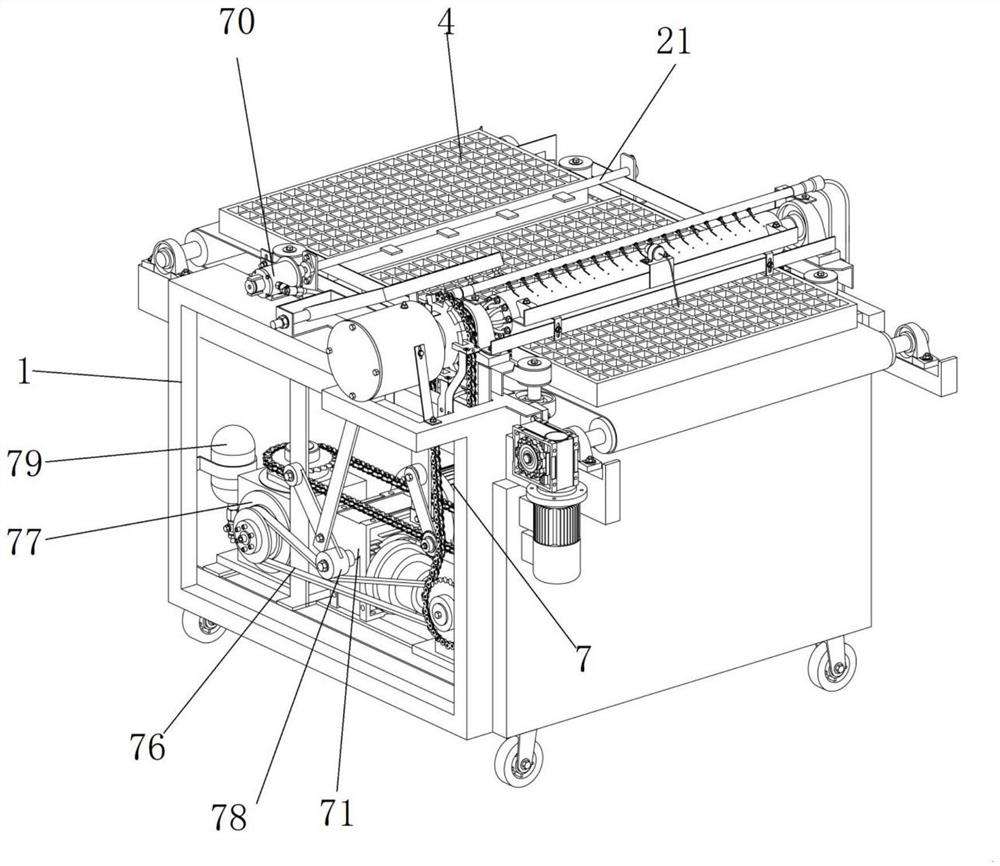

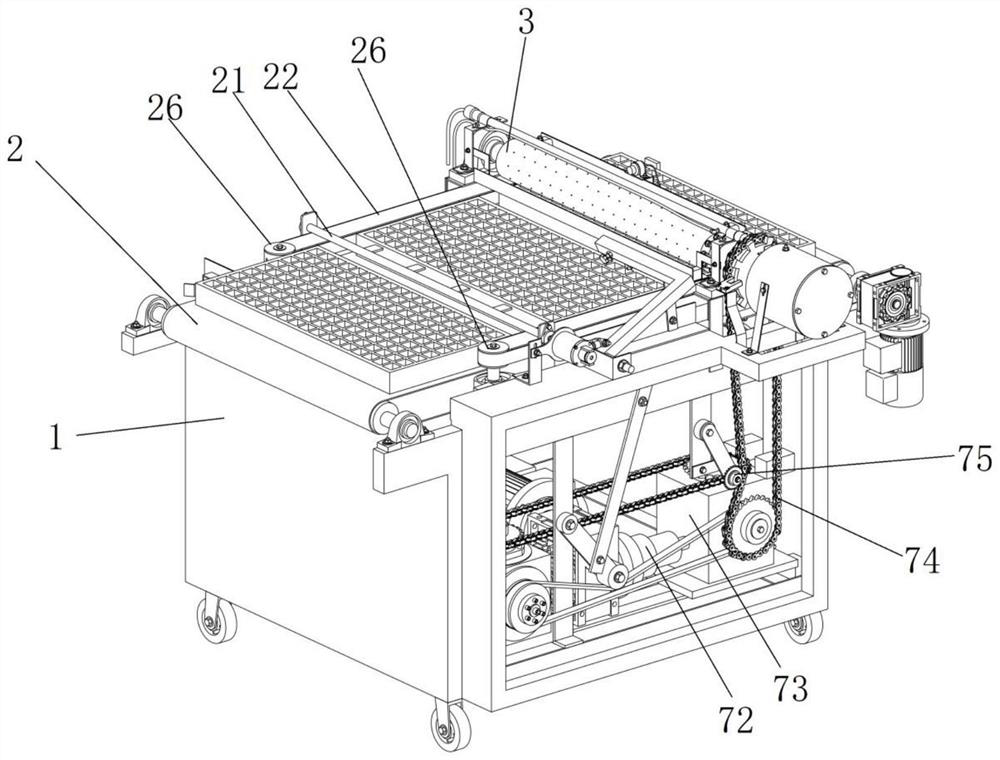

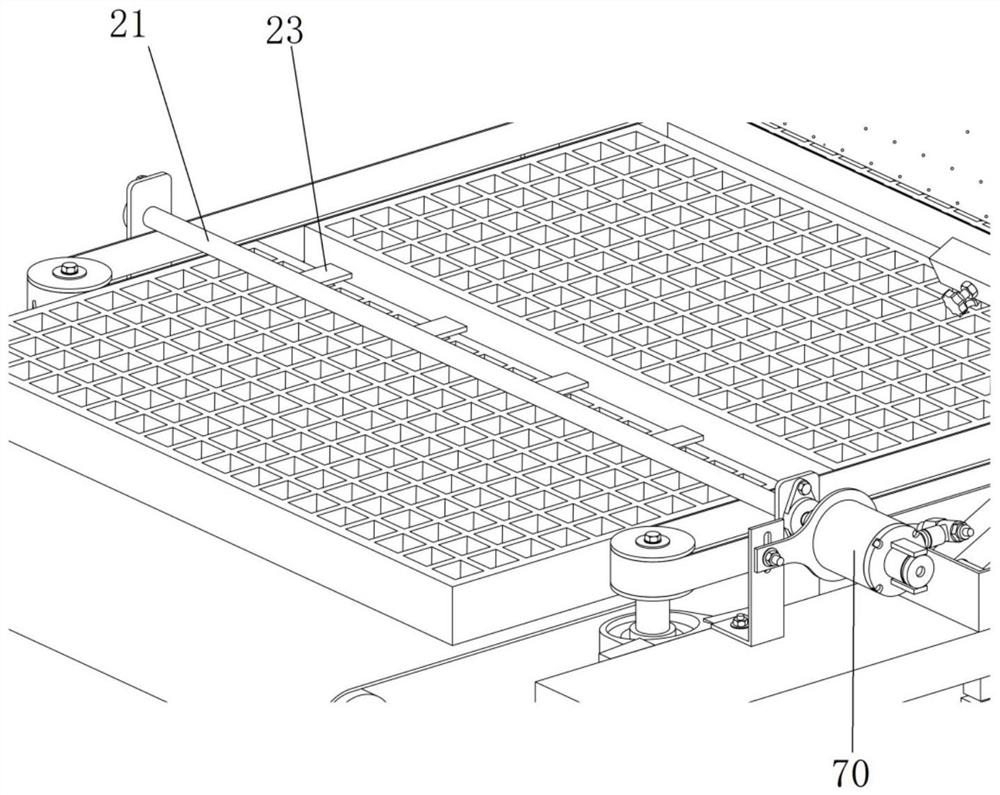

[0034] Embodiment 1: the power output mechanism, power transmission mechanism, pneumatic mechanism installed in the frame 1, the seedling raising tray advancing on the frame 1, the seedling raising tray 4 just above the direction of travel is provided with a pneumatic seeding roller 3, the seedling raising tray 4 Can pass under the pneumatic seeding drum 3, the pneumatic seeding drum 3 is provided with several rows of seeding holes 31 arranged along the length, the pneumatic seeding drum 3 can realize axial intermittent rotation through the power transmission mechanism, and seedling cultivation When the disc 4 passes through the bottom of the pneumatic seeding drum 3, it advances intermittently with the intermittent frequency of the pneumatic seeding drum 3 until the seedling raising disc 4 passes through the pneumatic seeding drum 3 and completes seeding in the seedling hole of the seedling raising disc. When the seedling tray 4 passes under the pneumatic seeding roller 3, it ...

Embodiment 2

[0037] Embodiment 2: The outer surface of the pneumatic seeding cylinder 3 connected to the power transmission mechanism of the present invention is arranged with several seeding holes 31 along the length direction, and each row of seeding holes 31 is radially distributed, and the pneumatic seeding cylinder 3 Each row of seeding holes 31 is in communication with a corresponding single air pipe 32, and the other end of the air pipe 32 is connected to the ventilation rotor, and the ventilation rotor is arranged at one end of the pneumatic seeding cylinder 3 and Located in a negative pressure chamber 324. The negative pressure box 324 is connected to the vacuum pump through a pipeline, so that the inside of the negative pressure box 324 is in a sealed negative pressure state, so that the air pipe 32 in the ventilation rotor is in a state of negative pressure when it is at an angle other than the seeding station. In the state of equal pressure, the negative pressure is connected t...

Embodiment 3

[0042] Embodiment 3: in combination with Figure 1-12Read this embodiment: a high-precision automatic seedling seeding device, including a frame 1, a power output mechanism installed in the frame 1, a power transmission mechanism, a pneumatic mechanism, and a seedling tray conveyor belt installed on the frame 1 2. The seedling tray conveyor belt 2 can move forward at a constant speed through the power transmission mechanism. A pneumatic seeding roller 3 is installed above the seedling tray conveyor belt 2. The pneumatic seeding roller 3 is provided with several rows of seeding holes arranged along the length 31: The pneumatic seeding drum 3 can realize axial intermittent rotation through the power transmission mechanism, and each rotation of the pneumatic mechanism can make the bottom seed 5 face the row of seedling holes 41 on the seedling tray 4 for seeding; The frame 1 is provided with a seedling tray 4 precise control mechanism, and the seedling tray 4 fine control mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com