Method for separating particles of valuable minerals, precious metals, rare earth metals, gemstones and sub-gemstones from natural ores by adhesion in aqueous environment

A technology for natural ore and water environment, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as low efficiency and narrow application range, and achieve the effect of eliminating technical defects and simple and cheap processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Example I:

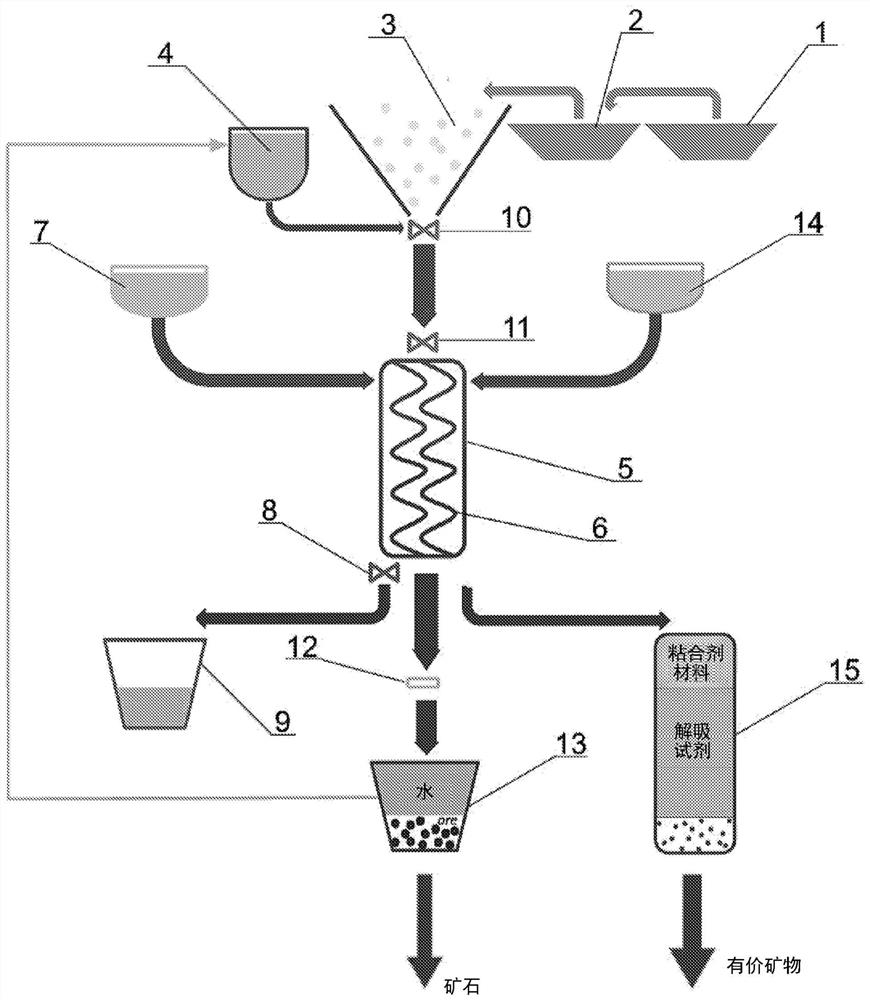

[0037] In the example of alluvial deposits located in Bulgaria, a method for separating particles of valuable minerals, precious metals, rare earth metals, precious and semi-precious stones from natural ores in an aqueous environment by adhesion phenomena in amounts of A ton of ore is about 2 grams of gold, in which the gold particles oscillate between a few micrometers and a few millimeters.

[0038] A portion of particles smaller than 3 mm was washed from the 100 kg of ore used for the test on the sieve. This fraction is magnetically separated in separator 2 to remove ferromagnetic particles. In other embodiments, the magnetic separation process may be omitted if the deposit does not contain ferromagnetic particles.

[0039] Subsequently, this purified ore portion is placed in pool 3, into which water from pool 4 is poured. In this way, 150 liters of suspension are formed in the tank 3 containing about 50 kg of an ore fraction with a particle size of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com