Pepper oil residue separation device

A technology of slag separation and pepper oil, which is applied in the field of pepper oil residue separation device, can solve the problems of pepper oil waste, pepper residue and pepper oil difficult to filter, and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

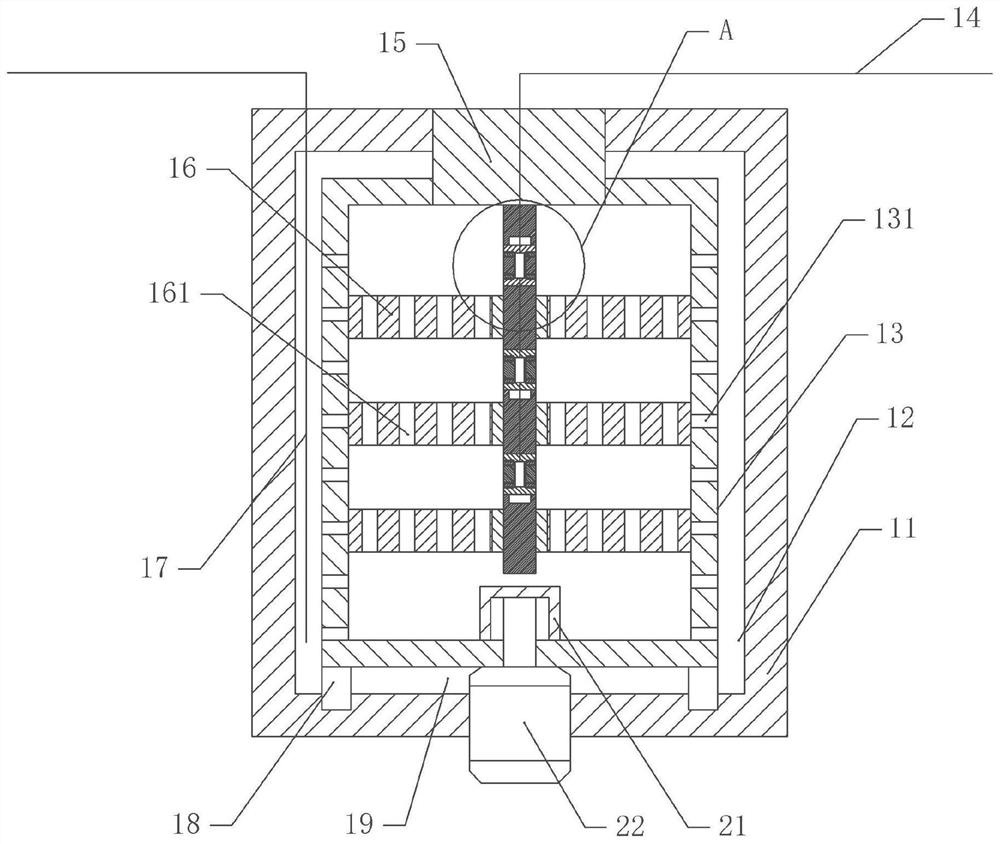

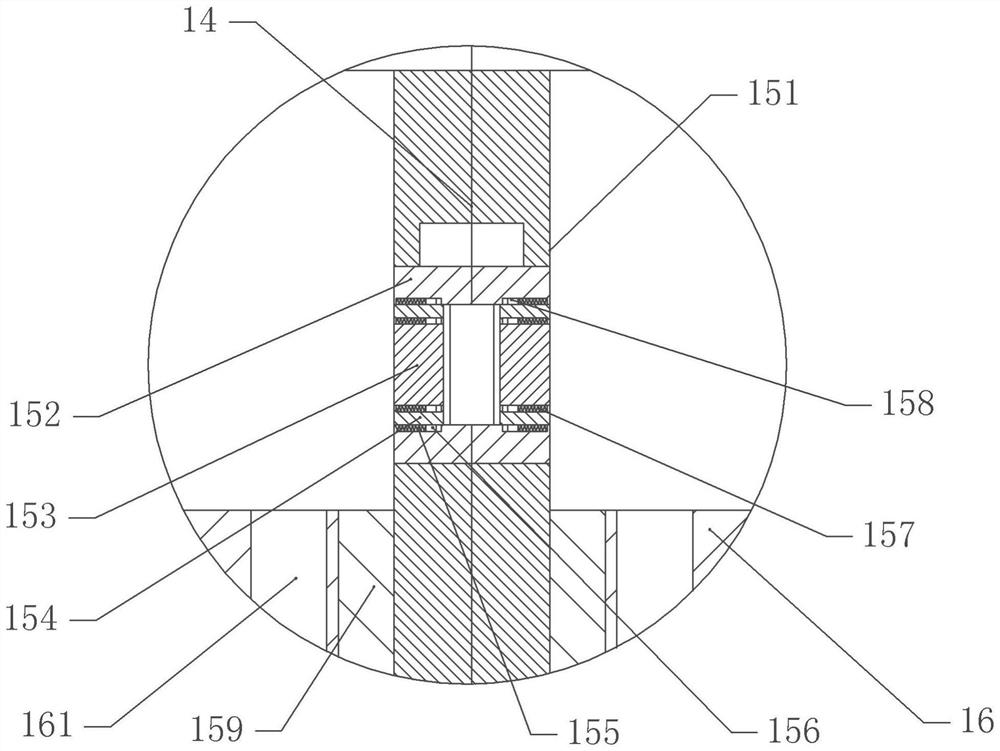

[0035] A kind of pepper oil residue separation device, such as attached figure 1 And attached figure 2 As shown, it includes a frame and an outer cylinder 11 fixed on the frame by bolts. An inner cylinder 13 is arranged in the outer cylinder 11. An oil chamber 12 is formed between the outer cylinder 11 and the inner cylinder 13. The outer cylinder 11 and the inner cylinder 13 The upper parts are all open, and the outer cylinder 11 is fixedly connected with a cover plate 15 by bolts, and the cover plate 15 is used to close the outer cylinder 11 and the inner cylinder 13 .

[0036] Bolts on the outer cylinder 11 are fixed with a driver, the driver is a motor 22, the output shaft of the motor 22 runs through the inner cylinder 13 and is fixedly connected with the inner cylinder 13 by bolts, the outer cylinder 11 is fixed with a cylindrical support plate 18, the outer cylinder 11 is rotatably connected to the inner cylinder 13 through the support plate 18, and the cavity 19 is f...

Embodiment 2

[0048] The difference between embodiment two and embodiment one is that, as attached image 3 As shown, it also includes a blower assembly located on one side of the outer cylinder 11, the blower assembly is a blower 32, and the blower 32 is communicated with a heater 31, and the heater 31 communicates with the lower part of the oil chamber 12, and the oil pipe 17 and the centrifugal pump are located in the outer cylinder On the other side of 11 , an air outlet 33 communicating with the oil chamber 12 is opened on the outer cylinder 11 .

[0049] In this embodiment, the blower 32 sends gas into the heater 31, and the gas is heated by the heater 31. For example, the temperature of the hot gas is about 50°C to send hot gas into the oil chamber 12. Of course, the hot gas will also pass through the oil hole 131 Into the inner cylinder 13, when the gas passes through the oil hole 131, the pepper residue on the oil hole 131 is blown into the inner cylinder 13, so as to prevent the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com