Metal element doped lead sulfide material, preparation method thereof and application of metal element doped lead sulfide material in metal element doped lead sulfide film

A metal element, lead sulfide technology, applied in lead sulfide, electrical components, semiconductor devices, etc., can solve problems such as doping in aqueous solution, achieve controllable doping concentration, good uniformity and photosensitive characteristics, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

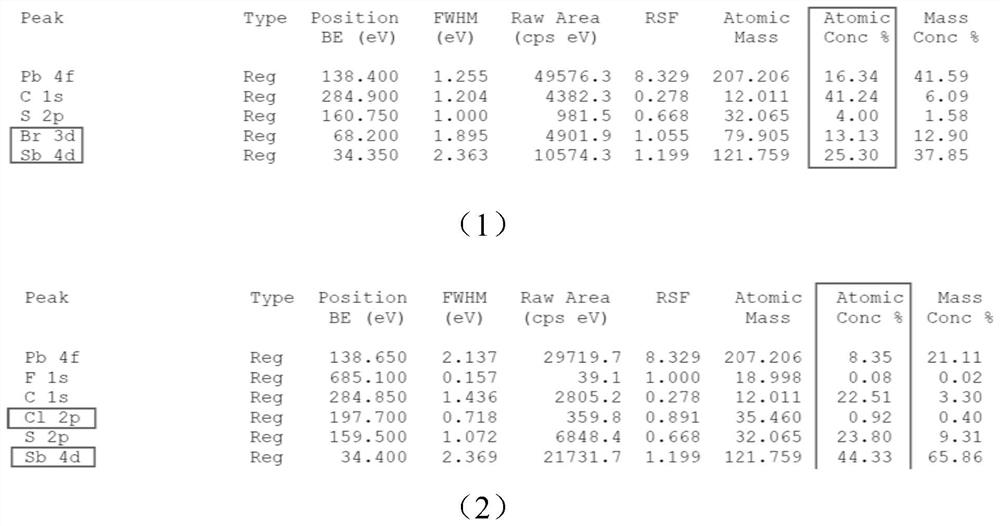

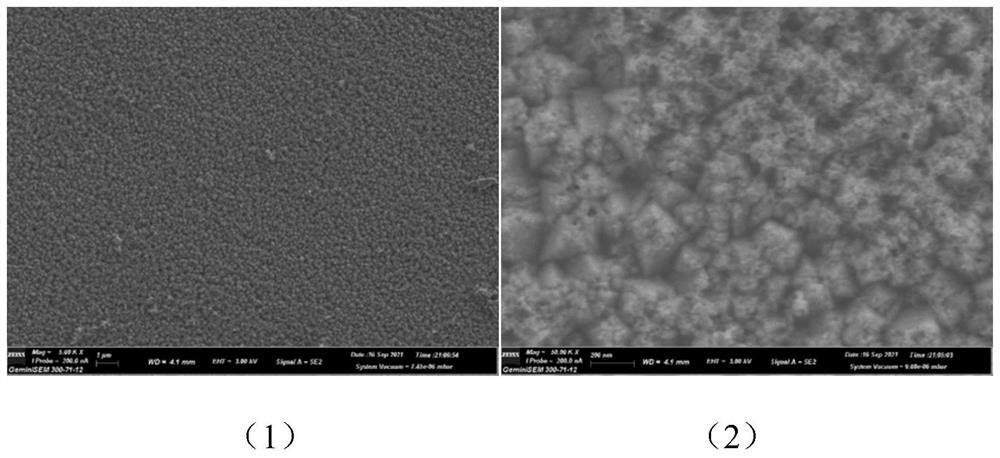

Embodiment 1

[0083] Step 1: Use sodium hydroxide deionized water to prepare a sodium hydroxide solution with a concentration of 0.01g / mL, and record it as solution G;

[0084] Step 2: Using lead nitrate (Pb(NO 3 ) 2 ) and deionized water preparation 18mmol / L lead nitrate solution, recorded as solution H;

[0085] Step 3: adopt thiourea and deionized water to prepare 1.5mol / L thiourea solution, denoted as solution I;

[0086] Step 4: Take a certain amount of solution G and add it to solution H to stabilize the pH value at 12.5, stir and then let it stand, and filter to obtain a clear solution J for later use.

[0087] Step 5: Ultrasonic clean the substrate with detergent, acetone, isopropanol, ethanol and deionized water for 15 minutes respectively, and after drying, place the substrate in a UV ozone or plasma cleaner for 5 minutes; Place the glass vertically or obliquely downwards in solution J, and store it at 25°C.

[0088] Step 6: Take solution I and slowly add it to the above solut...

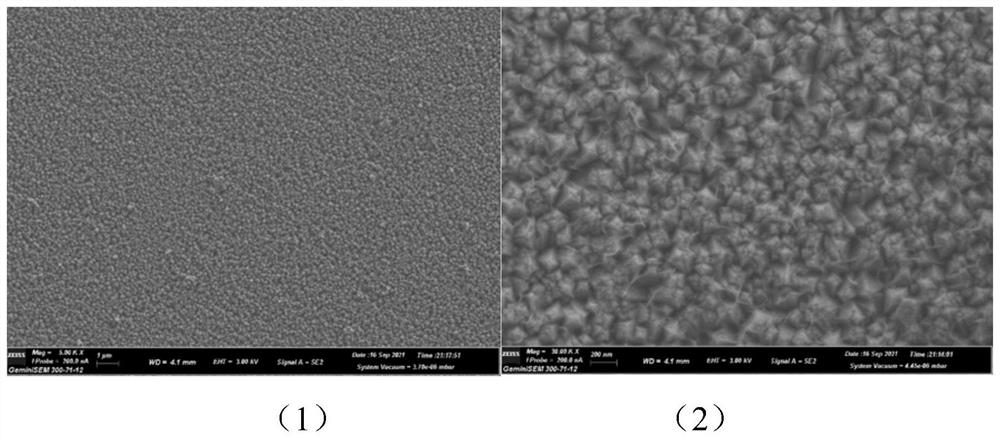

Embodiment 2

[0094] Step 1: Use sodium hydroxide deionized water to prepare a sodium hydroxide solution with a concentration of 0.01g / mL, and record it as solution G;

[0095] Step 2: Using lead nitrate (Pb(NO 3 ) 2 ) and deionized water preparation 18mmol / L lead nitrate solution, recorded as solution H;

[0096]Step 3: adopt thiourea and deionized water to prepare 1.5mol / L thiourea solution, denoted as solution I;

[0097] Step 4: Take a certain amount of solution G and add it to solution H to stabilize the pH value at 12.5, stir and then let it stand, and filter to obtain a clear solution J for later use.

[0098] Step 5: Ultrasonic clean the substrate with detergent, acetone, isopropanol, ethanol and deionized water for 15 minutes respectively, and after drying, place the substrate in a UV ozone or plasma cleaner for 5 minutes; Place the glass vertically or obliquely downwards in solution J, and store it at 25°C.

[0099] Step 6: Take solution I and slowly add it to the above soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com