Automatic cutting machine for net film

A cutting machine, automatic technology, applied in the direction of cleaning method using gas flow, winding strips, sending objects, etc., can solve the problems of difficult cutting dust, uncut, film pushing, etc., to reduce manpower input and speed up Improvement of process time and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

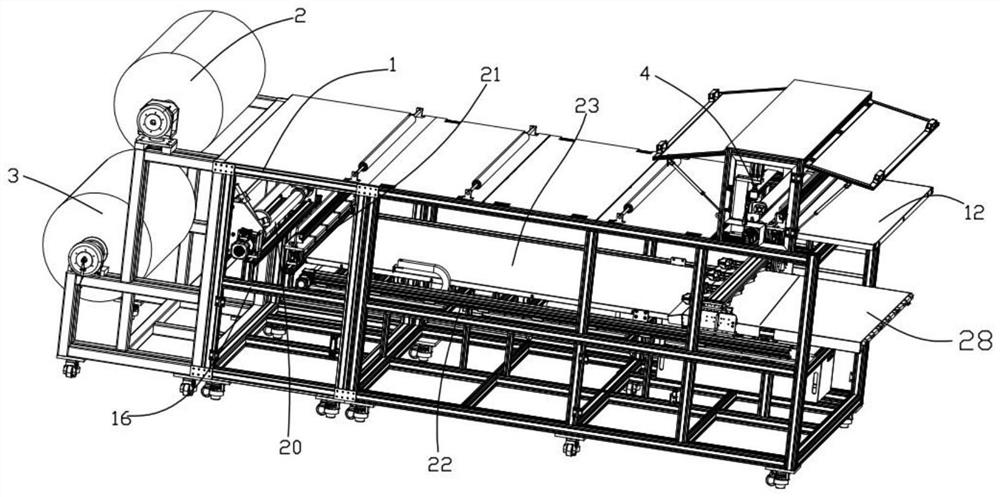

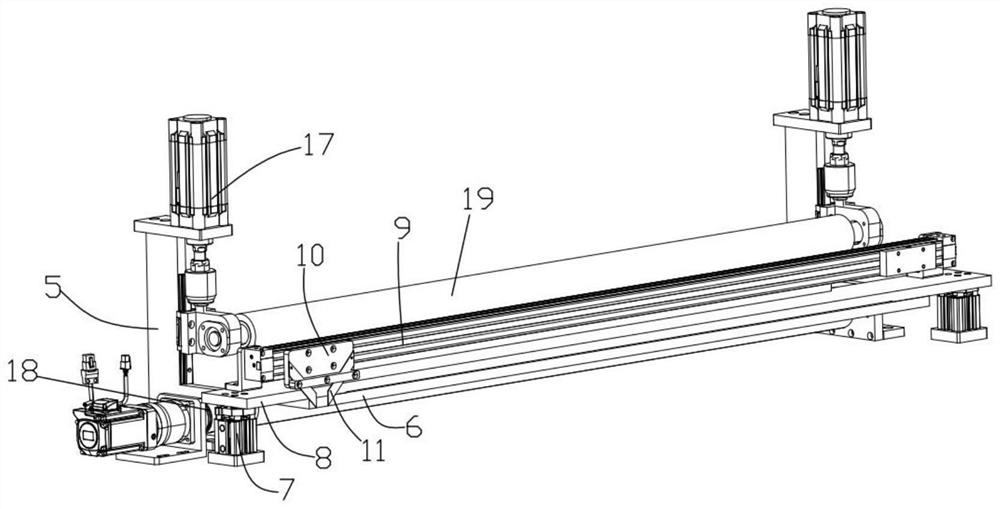

[0026] Such as figure 1 As shown, the present invention proposes a retinal automatic cutting machine including upper brackets 1 and a lower bracket 16, and the upper bracket 1 is provided with a first film roller 2 and a pulling a weapon assembly 4, such as figure 2 As shown, the pulled cutting assembly 4 includes a first rack 5, and a pull film mechanism is provided on one side of the pulled membrane mechanism, a first film roller. 2 Used to place the ST film, the second membrane roller 3 of the lower bracket 16 is used to place the retina, the first film roller 2 and the second film roller 3 are respectively provided with a counter, for calculating the first film roller 2 and The length of the material discharged from the second film roller 3;

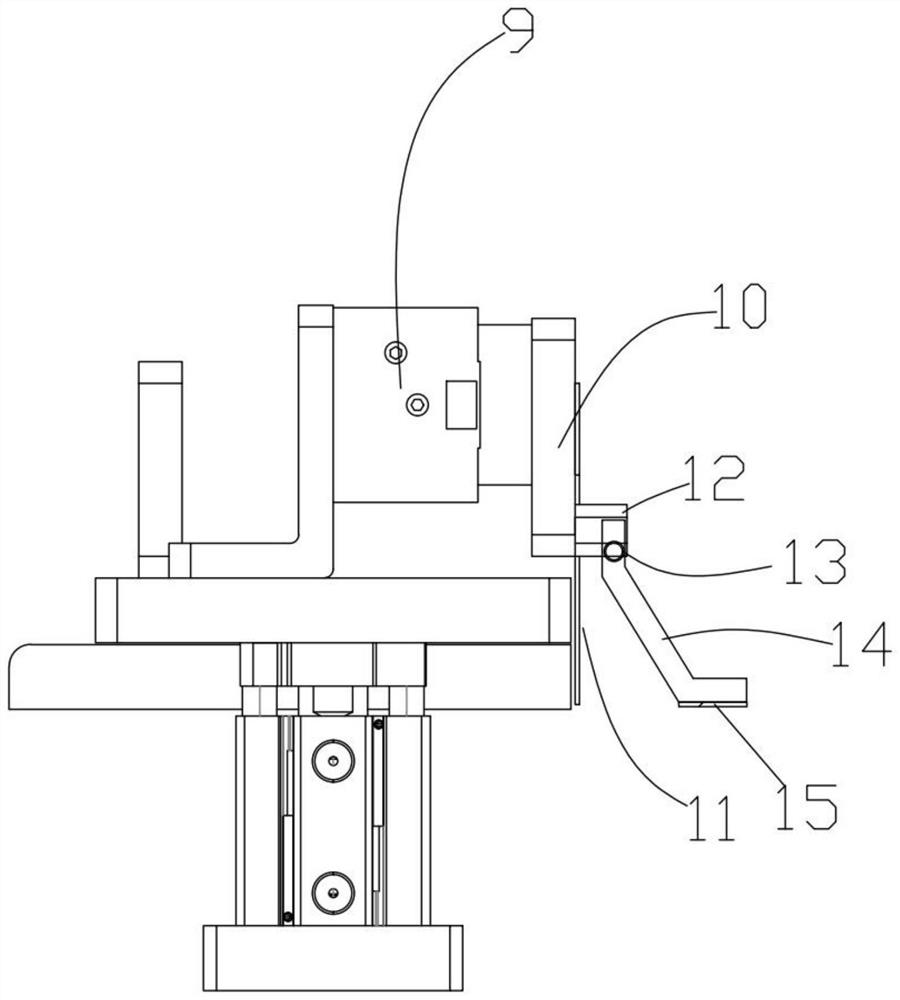

[0027] The first cutting mechanism includes a carrier plate 6, and the carrier pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com