Tunnel noise reduction system and preparation method thereof

A noise reduction system and noise reduction technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as noise expansion, high management costs, and noise formation, and achieve the goals of accelerating noise consumption, improving visual environment, and improving use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

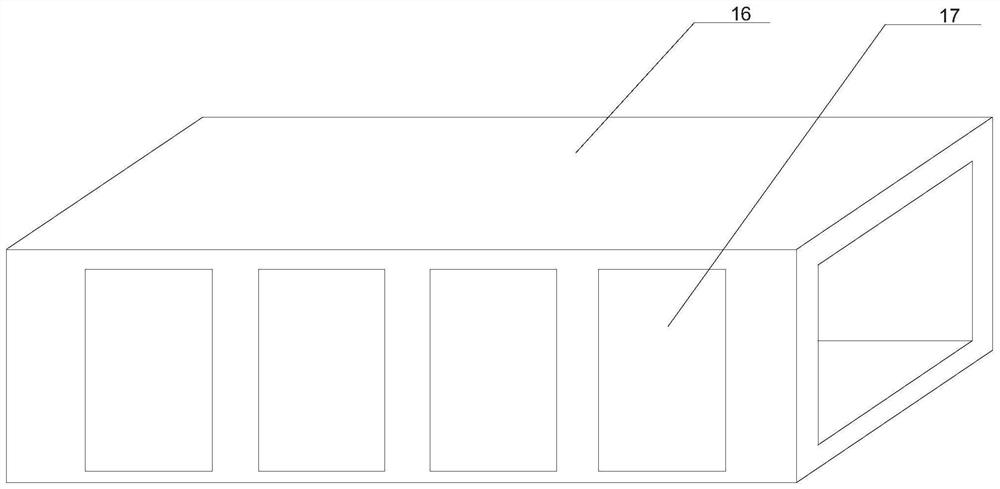

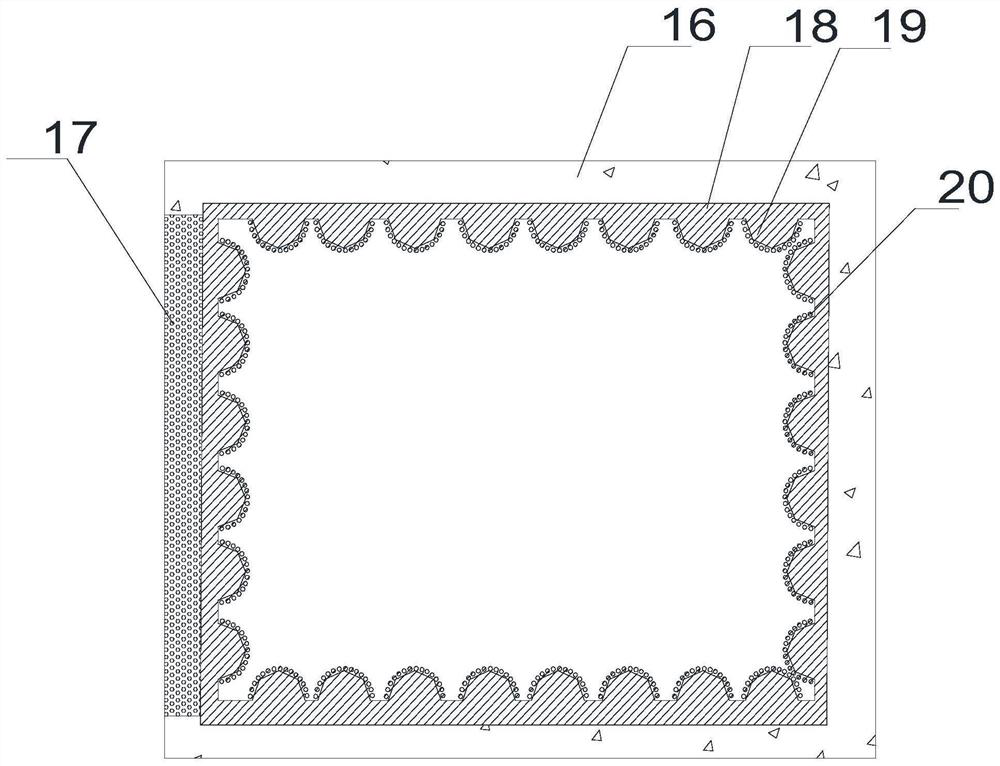

[0033] Such as figure 1 As shown, the system includes a muffler box body 16 with a cavity inside, and a sound-absorbing panel 18 is arranged on one side of the muffler box body 16, as figure 2 As shown, a cavity rubber layer 18 and a number of rubber projections 19 arranged on the cavity rubber layer 18 are provided on the inner surface of the sound-absorbing box body 16 , and a sound-absorbing layer 20 is provided on the rubber projections 19 . In this embodiment, the material of the sound-absorbing board 18 is volcanic rock. The sound-absorbing layer 20 includes volcanic rock particles.

[0034] In this embodiment, several openings are provided on one side of the muffler box body 16, and the openings communicate with the inside of the muffler box body 16, and the sound-absorbing panels are arranged on several openings on the sides of the muffler box body 16. In this embodiment, , first put the steel frame in the mold of the sound-absorbing box body, add C15 concrete, etc....

Embodiment 2

[0037] On the basis of Example 1, such as figure 1 As shown, the left and right ends of the sound-absorbing box body 16 are open. In this embodiment, several sound-absorbing sound box bodies 16 are included, and the left and right ends of the sound-absorbing sound box body 16 are connected sequentially. After the sound-absorbing board, the cavity rubber layer 18, the rubber protrusion 19 and the sound-absorbing layer are arranged on the sound-absorbing box body 16, the sound-absorbing and noise-reducing box is obtained, and the left and right ends of several sound-absorbing and noise-reducing boxes are connected in sequence, and the sound-absorbing and noise-reducing boxes after connection are connected. The box is placed on the tunnel curb with the acoustic panel 18 facing the road of travel, resulting in a noise reduction system. In this embodiment, several noise reduction and noise reduction boxes in the noise reduction system are arranged along the curb in the tunnel, so t...

Embodiment 3

[0039] On the basis of Embodiment 2, a sound-absorbing panel 18 is provided on one side of the sound-absorbing box 16, such as figure 2 As shown, a cavity rubber layer 18 and a number of rubber projections 19 arranged on the cavity rubber layer 18 are provided on the inner surface of the sound-absorbing box body 16 , and a sound-absorbing layer 20 is provided on the rubber projections 19 . In this embodiment, the material of the sound-absorbing board 18 is volcanic rock. The sound-absorbing layer 20 includes volcanic rock particles, and the diameter of the rubber protrusions 19 is 5 cm. The ratio of the diameter of the rubber protrusion 19 to the diameter of the volcanic rock particles is 5:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com