Sandwich plate fused deposition printing supporting structure generation method and system

A support structure and sandwich board technology, applied in the field of additive manufacturing, can solve the problems of less research on support design, no consideration of impact, and increased printing costs, so as to improve the redundancy of support points and make up for more supports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

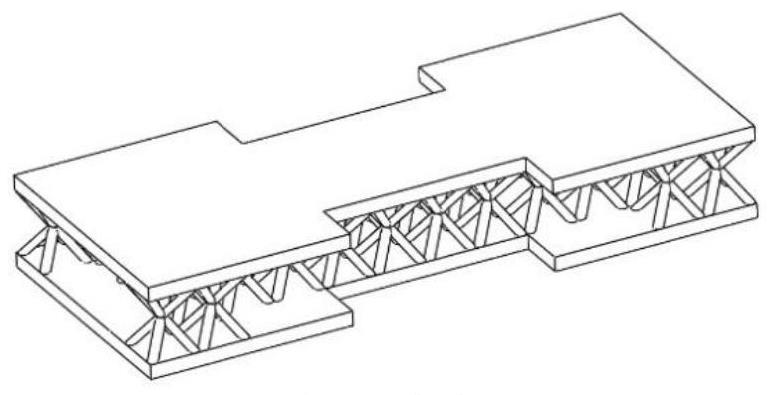

[0042] This embodiment provides a method for generating a sandwich plate fused deposition printing support structure, including:

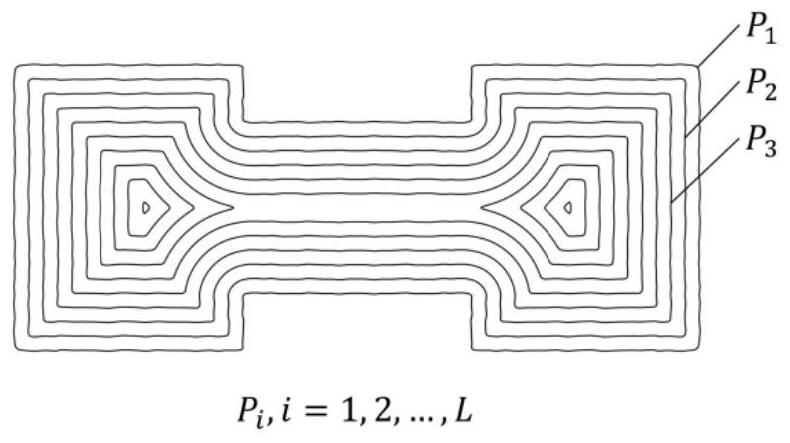

[0043] Obtain multiple sets of equidistant path profile information on the target part surface, and calculate the discrete curvature of the path profile;

[0044] Based on the corresponding relationship between the discrete curvature of the path profile and the maximum support distance, the discrete support points of the outermost path are obtained through segmental processing;

[0045] By shrinking the discrete support points of the outermost path to the inner path along the gradient direction, the set of support points of the entire target part surface is obtained;

[0046] According to the set of support points, the STL model of the support structure is generated by using the level set method.

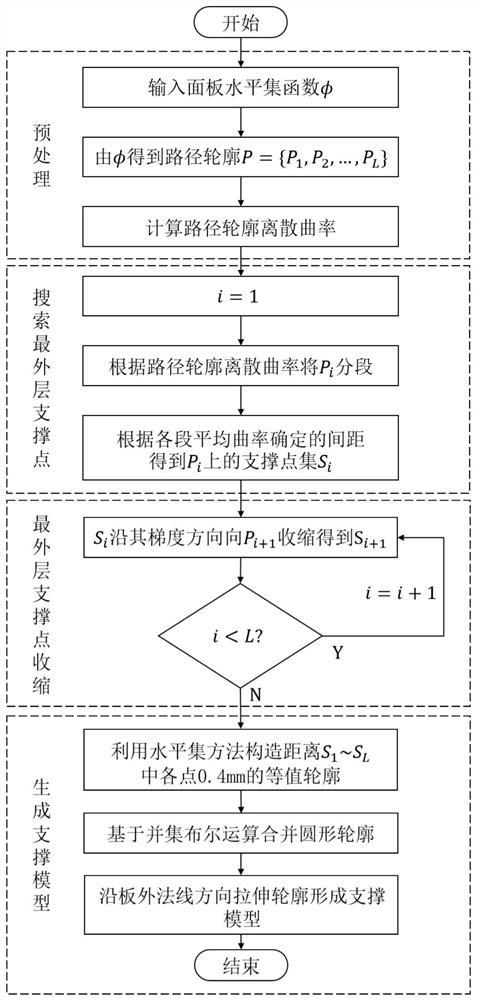

[0047] Specifically, such as figure 1 As shown, it mainly includes four parts: target part preprocessing, searching for the outermost support point, s...

Embodiment 2

[0072] This embodiment provides a sandwich plate fused deposition printing support structure generation system, including:

[0073] The path profile discrete curvature calculation module is used to obtain multiple sets of equidistant path profile information on the surface of the target part, and calculate the path profile discrete curvature;

[0074] The discrete support point acquisition module is used to obtain the discrete support points of the outermost path through segment processing based on the corresponding relationship between the discrete curvature of the path profile and the maximum support distance;

[0075] The support point set acquisition module is used for shrinking the discrete support points of the outermost path to the inner path along the gradient direction to obtain the support point set of the entire target part board;

[0076] The support structure STL model generation module is used for generating the support structure STL model by using the level set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com