Multifunctional ski socks

A ski socks, multi-functional technology, applied in socks, pantyhose, clothing, etc., can solve the problems of single shape and structure, no special structural support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

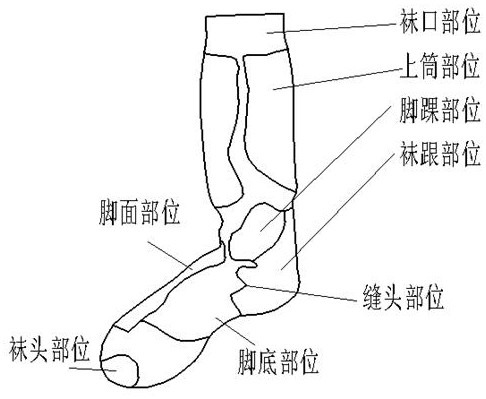

[0051] A multi-functional ski sock, the ski sock includes a sock opening, upper tube, ankle, heel, instep, sole, toe and seam; the needle type of the ski socks is 168N, The seam method adopts the eye.

[0052] in:

[0053] The sock opening is made of 1205050 Lycra high-resilience elastic and merino wool; it is designed with a pearl mesh structure, and the sock opening is designed with no bottom yarn; the sock opening has good wrapping properties and is not easy to slip off the leg; and it has excellent elasticity, Do not strangle the legs;

[0054] The knitting method of the sock mouth is as follows: the sock collar is threaded at a height of 7 cm and a width of 9.8 cm, and the No. 7 shuttle, No. 1 shuttle and elastic shuttle in the main shuttle enter the thread at the same time, and the weaving is completed in the same direction for 80 turns; The structure of 1205050 Lycra double-wrapped spandex in the circle is in 168 stitches 360 degrees; the first stitch of the first cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com