Sulfide ore flame retardant method based on microorganism-inhibitor comprehensive effect

A technology of comprehensive action and chemical inhibitor, applied in mining equipment, earth-moving mining, dust prevention, etc., can solve the problems of ore partition inside sulfide ore pile, increase operating cost, short duration, etc. The effect of preventing and controlling the spontaneous combustion of sulfide ore and reducing the tendency of spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] Step 1. Cultivate acidophilic thermophilic Thiobacillus to obtain cultured bacterial liquid; the cultivation process is: use sterilized 9K medium to inoculate acidophilic Thermophilic Thiobacillus, and use elemental sulfur as the nutrient substance of bacteria , sealed after inoculation, and then put into a rotating speed of 175rpm, and the temperature was cultivated for 6 days in a constant temperature shaker at 43°C; the medium was Silverman's liquid medium; ), from the laboratory of the School of Resource Processing and Bioengineering, Central South University; address: School of Resource Processing and Bioengineering, No. 932, Lushan South Road, Yuelu District, Changsha City, Hunan Province;

[0030] Step 2, mix the sulfide ore and the cultured bacterial solution obtained in step 1 and then add the immersion aid to obtain the mixture, then put the obtained mixture into a sealed container and carry out desulfuriz...

Embodiment 2

[0066] This embodiment includes the following steps:

[0067] Step 1. Cultivate acidophilic thermophilic Thiobacillus to obtain cultured bacterial liquid; the cultivation process is: use sterilized 9K medium to inoculate acidophilic Thermophilic Thiobacillus, and use elemental sulfur as the nutrient substance of bacteria , sealed after inoculation, and then put into a rotating speed of 170rpm, and the temperature was cultivated in a constant temperature shaker at 40°C for 8 days; the medium was Silverman's liquid medium; ), from the laboratory of the School of Resource Processing and Bioengineering, Central South University; address: School of Resource Processing and Bioengineering, No. 932, Lushan South Road, Yuelu District, Changsha City, Hunan Province;

[0068] Step 2, mix the sulfide ore and the cultured bacterial solution obtained in step 1 and then add the immersion aid to obtain the mixture, then put the obtained mixture into a sealed container and carry out desulfuriz...

Embodiment 3

[0074] This embodiment includes the following steps:

[0075] Step 1. Cultivate acidophilic thermophilic Thiobacillus to obtain cultured bacterial liquid; the cultivation process is: use sterilized 9K medium to inoculate acidophilic Thermophilic Thiobacillus, and use elemental sulfur as the nutrient substance of bacteria , sealed after inoculation, and then put into a rotating speed of 173rpm, and the temperature was cultivated for 4 days in a constant temperature shaker at 45°C; the medium was Silverman's liquid medium; the Acidithiobacillus caldus ), from the laboratory of the School of Resource Processing and Bioengineering, Central South University; address: School of Resource Processing and Bioengineering, No. 932, Lushan South Road, Yuelu District, Changsha City, Hunan Province;

[0076] Step 2, mix the sulfide ore and the cultured bacterial solution obtained in step 1 and then add the immersion aid to obtain the mixture, then put the obtained mixture into a sealed conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

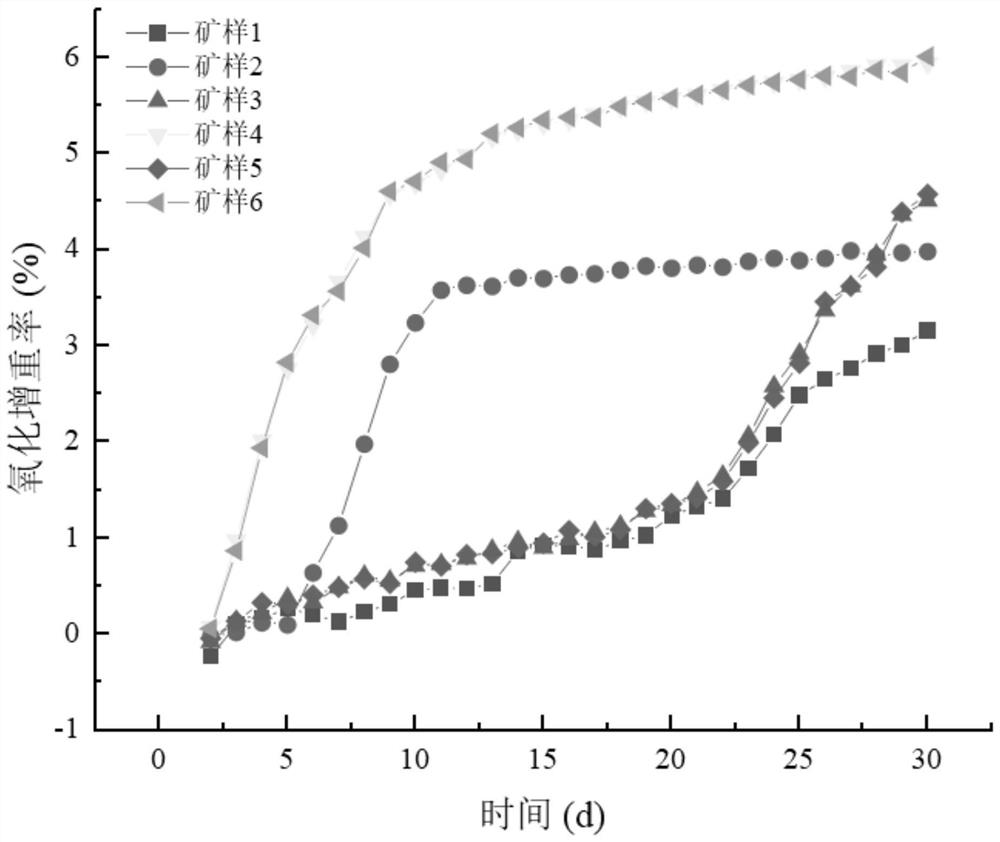

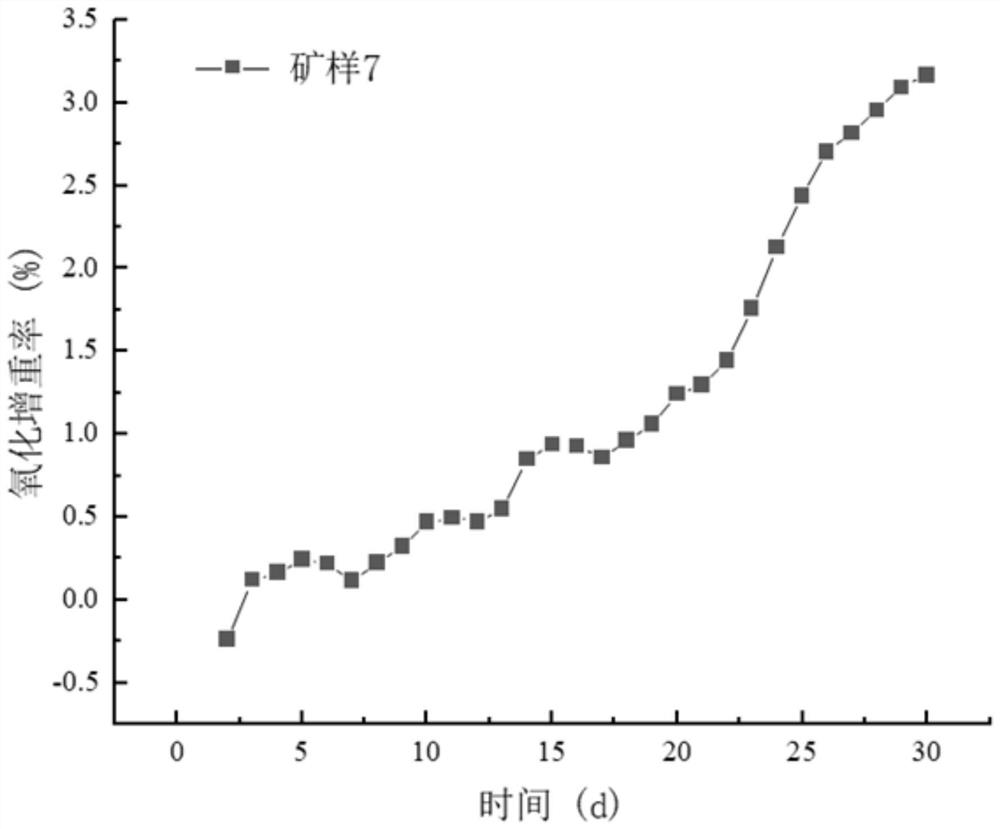

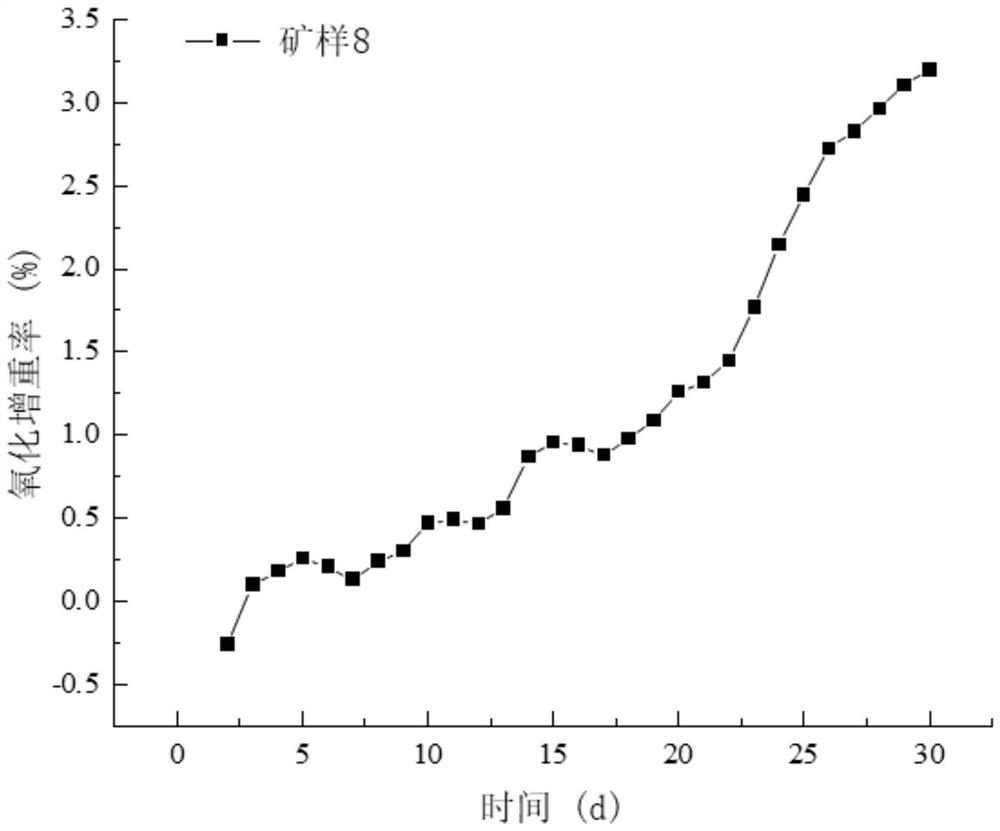

| oxidation rate | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com