A kind of etching method for single-sided germanium wafer

A wafer, single-sided technology, applied in the field of germanium wafer processing, can solve the problems of germanium wafer surface damage, germanium wafer grinding and thinning processing efficiency, increase the surface roughness of germanium wafers, etc., to achieve increased stability, good cleaning effect, The effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

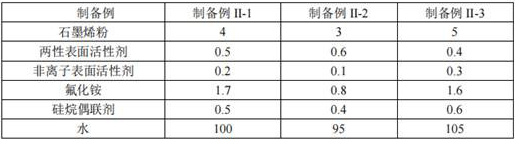

Examples

preparation example I-1

[0051] An acid etching solution, the acid-resistant cationic surfactant is octadecyltrimethylammonium chloride; the mass fraction of concentrated hydrofluoric acid is 35%, the mass fraction of concentrated nitric acid is 60%; the mass fraction of glacial acetic acid is 99% %.

[0052] The acid etching solution is prepared by the following methods:

[0053] Add 90kg of concentrated hydrofluoric acid and 10kg of glacial acetic acid to 10kg of concentrated nitric acid, stir for 3min, then add 40kg of water, continue to stir for 5min, cool down to 25°C, then add 0.5kg of acid-resistant cationic surfactant, and continue to stir for 10min, It was left to stand for 20 minutes to obtain an acid etching solution.

preparation example I-2

[0055] An acid etching solution, which is different from Preparation Example I-1 in that the raw materials of the acid-resistant cationic surfactant are different, and the rest are the same. And, the acid-resistant cationic surfactant is a mixture of octadecyltrimethylammonium chloride and octadecylamine acetate, and octadecyltrimethylammonium chloride, octadecylamine acetate The weight ratio is 1:1.

preparation example I-3

[0057] An acid etching solution, which is different from Preparation Example I-1 in that the raw materials of the acid-resistant cationic surfactant are different, and the rest are the same. And, the acid-resistant cationic surfactant is a mixture of octadecyltrimethylammonium chloride, dioctadecyldimethylammonium chloride, octadecylamine acetate, and octadecyltrimethylammonium chloride. The weight ratio of ammonium chloride, dioctadecyldimethylammonium chloride and octadecylamine acetate is 1.5:3:1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com