Distributing and conveying device for labeling of bottom covers of milk powder cans

A technology of conveying device and material distributing device, applied in conveyors, labeling machines, transportation and packaging, etc., can solve the problems of high equipment cost, long action cycle, uneven magnetization of iron cover, etc., and achieve accurate labeling position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

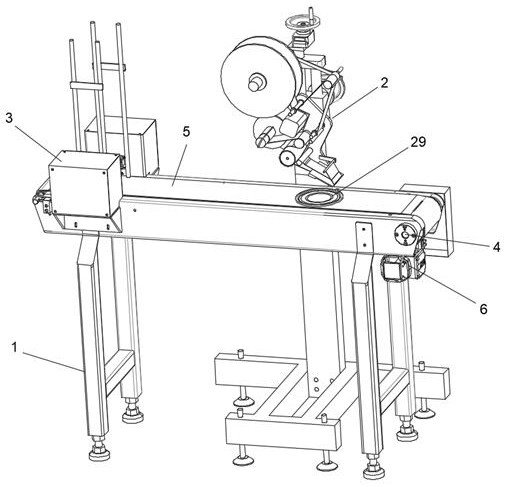

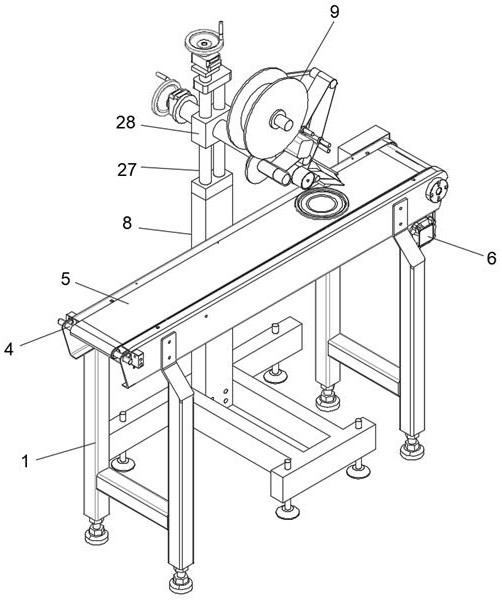

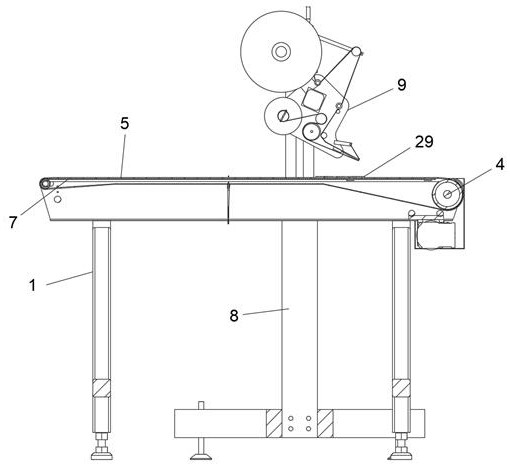

[0026] Embodiment one, such as Figure 1-6 As shown, a material distributing conveying device for labeling the bottom cover 29 of a milk powder tank includes a fixed bracket 1, a vertical labeling machine 2 and a material distributing device 3, and both ends of the fixed bracket 1 are movably connected with a conveying shaft 4, The surface of the conveying shaft 4 is sleeved with a conveyor belt 5, and one end of the fixed bracket 1 is fixedly installed with a transmission motor 6, and the driving end of the transmission motor 6 is rotationally connected with one of the conveying shafts 4 through gears, and the inner surface of the conveyor belt 5 is fixedly installed with a magnetic Material 7; the vertical labeling machine 2 includes a labeling machine support 8 and a labeling head 9, the labeling machine support 8 is arranged on one side of the fixed support 1, and the labeling head 9 is installed on the labeling machine support 8, and the labeling machine The labeling end ...

Embodiment 2

[0029] Embodiment two, such as Figure 3-6 As shown, as a further solution of Embodiment 1, the material distribution device 3 includes a support 10, and the support 10 is respectively fixedly installed on both sides of the feed end of the conveyor belt 5, and a bottom plate 11 is installed on the top of the support 10 by bolts, and on the bottom plate 11 The surface is fixedly installed with a first telescopic cylinder 12, and an upper plate 13 is arranged above the first telescopic cylinder 12. The upper plate 13 is fixedly connected with the bottom plate 11 through a vertical plate 14, and a second telescopic cylinder 15 is fixedly installed on the upper surface of the upper plate 13. The telescopic end of a telescopic cylinder 12 is fixedly equipped with a lower supporting plate 16, the telescopic end of the second telescopic cylinder 15 is fixedly equipped with an upper supporting plate 17, and a bottom of a milk powder tank is reserved between the lower supporting plate 1...

Embodiment 3

[0031] Embodiment 3, as a further solution of Embodiment 2, a fixed pressing block 19 is fixedly installed above the upper supporting plate 17 . After the extension of the upper supporting plate 17 is controlled by the second telescopic cylinder 15, the bottom cover 29 of the milk powder tank between the two distributing devices 3 can be compressed and fixed by the fixed pressing block 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com