Injection-blow molding intramode labeling technology

An in-mold labeling and injection blow molding technology, which is applied in the field of injection blow molding in-mold labeling technology, can solve the problems of low labeling position accuracy, high production cost, and poor anti-counterfeiting performance, so as to avoid secondary pollution , production cost reduction, good anti-counterfeiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a further detailed description of an injection blow molding in-mold labeling process according to the present invention through specific examples.

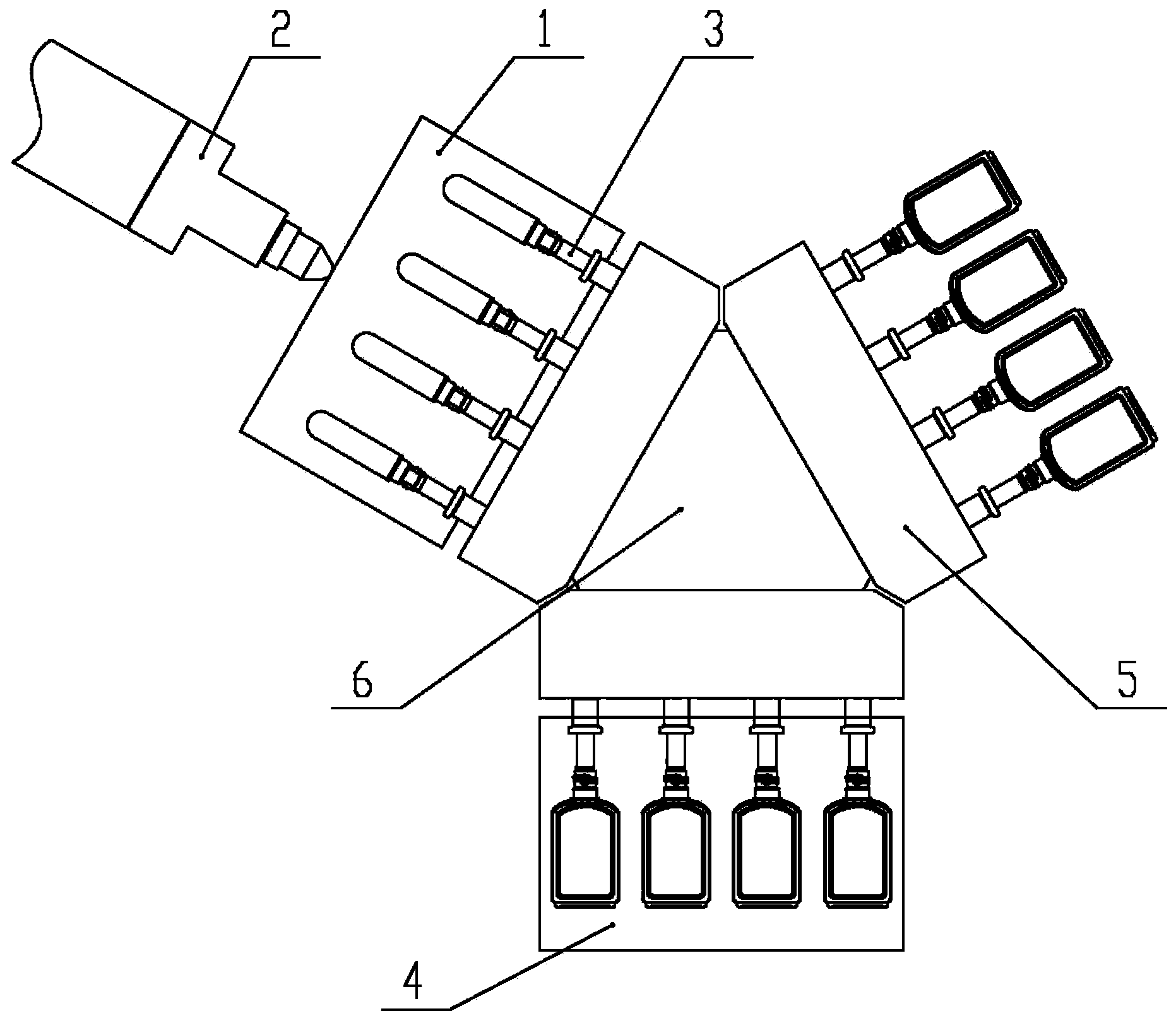

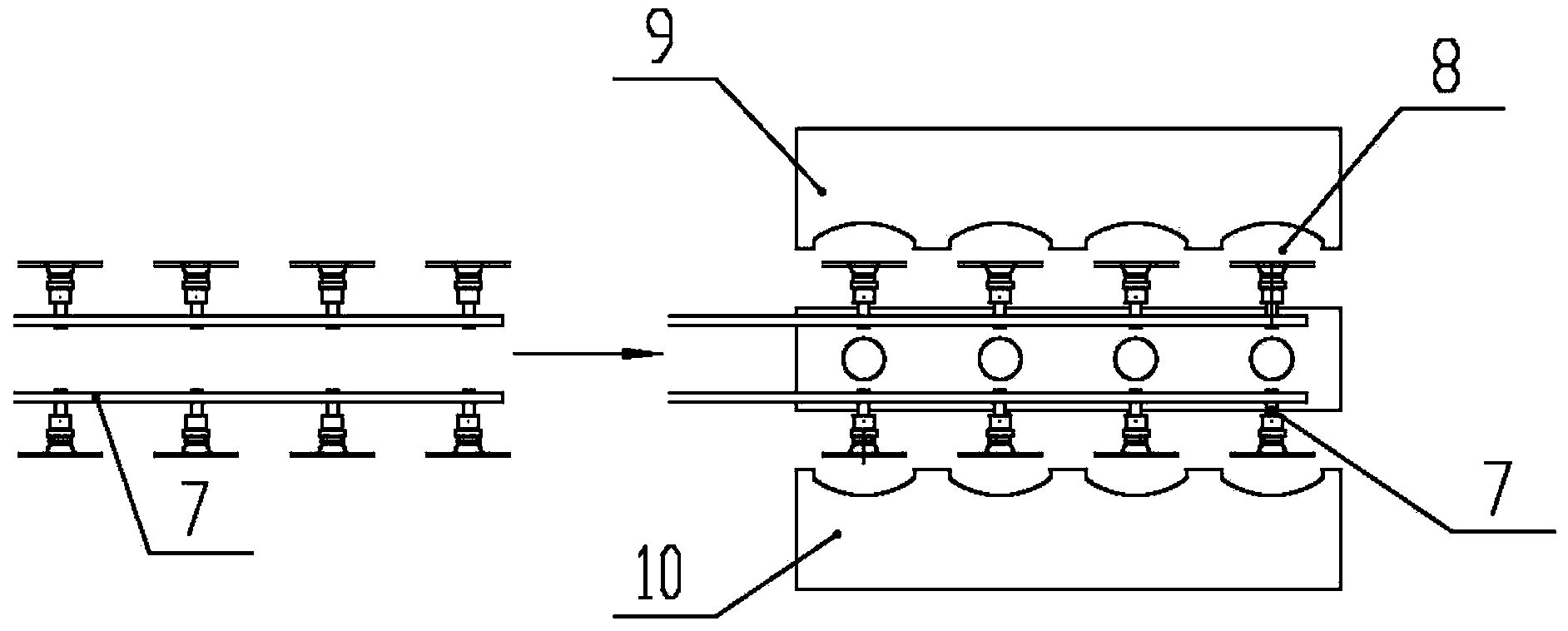

[0023] Such as figure 1 with figure 2 As shown, an injection-blow molding in-mold labeling process is generally realized on an injection-blow molding machine. The injection-blow molding machine includes three stations of injection molding, blow molding and demoulding with a distance of 120°, and a rotary lifting Components, three sets of mandrels are set on the rotary lifting component, which correspond to the positions of the three stations respectively. The process includes the following steps:

[0024] (1) On the injection molding station 1, the molten material part 2 is stored and injected, and the parison is formed on the mandrel 3. At the same time, the step (10) is carried out on the blow molding station 4, and the step (10) is carried out on the demoulding station 5. 13);

[0025] (2) Injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com