A post-labeling and positioning device for socks paper cards

A positioning device and paper card technology, applied in the directions of labeling, labeling machines, labels, etc., can solve the problems of difficulty in accurate labeling, and the labeling cannot be applied to both sides at one time, and achieves reasonable design, reduced labor costs, and improved labeling. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

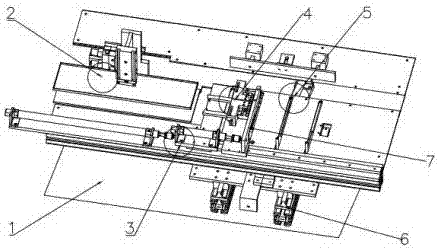

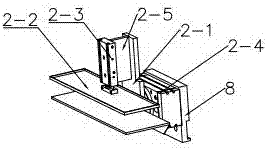

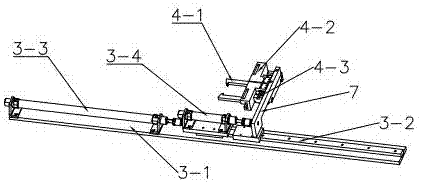

[0016] Such as Figure 1-4 As shown, a labeling and positioning device for sock paper cards includes a bracket 1 on which a rotating sock assembly 2, a cylinder transmission assembly 3, a sock clip positioning assembly 4 and a paper card positioning transmission assembly 5 are arranged. The paper card positioning transmission assembly 5 is slidably connected to the bracket 1 through the linear guide rail 6, the air cylinder transmission assembly 3 is fixedly connected to the paper card positioning transmission assembly 5, and the sock positioning assembly 4 is connected to the air cylinder transmission assembly 3 through the connecting plate 7 Slidingly connected, the sock clip positioning assembly 4 is arranged above the paper card positioning transmission assembly 5, the rotating sock assembly 2 is matched with the sock clip positioning assembly 4, and the rotating sock assembly 2 is fixed on the bracket 1 through a fixing member 8, The rotating sock assembly 2 includes a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com