Electrospray ion source and ionization method based on electrospray technology

An electrospray ion source and ionization technology, which is applied in the field of ion sources, can solve the problems of low ion collection rate, low ionization efficiency, and low desolventization efficiency, and achieve improved ion transmission effect, good ion transmission effect, and easy desolvation. The effect of solvation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

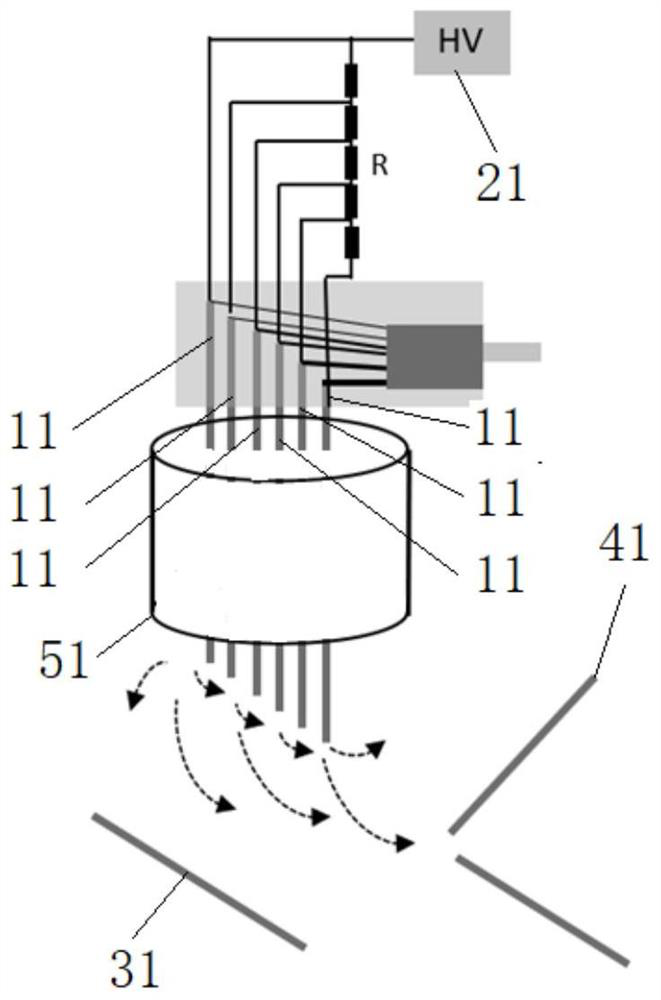

[0030] figure 1 A schematic structural view of the electrospray ion source of the embodiment of the present invention is given, as figure 1 As shown, the electrospray ion source includes:

[0031] A plurality of capillaries 11, the plurality of capillaries 11 arranged vertically are arranged in multiple rows, and from left to right, the height of the bottom end of each row of capillaries 11 gradually becomes lower;

[0032] A power supply 31 , the power supply 31 applies voltage to the capillary tubes 11 , the voltage of each column of capillary tubes 11 is the same, and the voltage of each column of capillary tubes 11 gradually decreases from left to right.

[0033] In order to improve the desolvation effect, further, the electrospray ion source also includes:

[0034] A gas conduit 51 surrounding the plurality of capillaries 11 .

[0035] In order to adapt to the liquids to be tested with different flow rates, furthermore, from left to right, the inner diameter of each ro...

Embodiment 2

[0049] An application example of the electrospray ion source and the ionization method based on electrospray technology according to Embodiment 1 of the present invention.

[0050] In this application example, if figure 1 As shown, a plurality of capillary tubes 11 are vertically arranged and arranged in multiple rows, and the height of the bottom end of each row of capillary tubes 11 is the same, and from left to right, the height of the bottom end of each row of capillary tubes 11 gradually becomes lower; each row of capillary tubes 11 The inner diameters of the capillaries are the same, and from left to right, the inner diameters of each row of capillary tubes 11 gradually become larger;

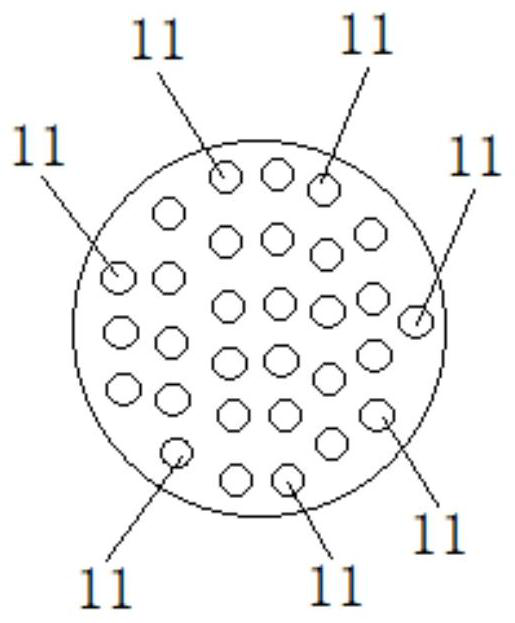

[0051] Such as figure 2 As shown, all capillary tubes 11 are in the same circle, and from left to right, the number of capillary tubes 11 in each column becomes larger and then smaller;

[0052] The power supply 21 applies a voltage to the capillary 11, the voltage of each column of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com