Dry-type transformer with high safety performance

A dry-type transformer and safety performance technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of low safety performance, dry-type transformer damage, affecting the progress of power distribution, etc., to ensure continuous normal use and reduce the possibility of burnout , Conducive to the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

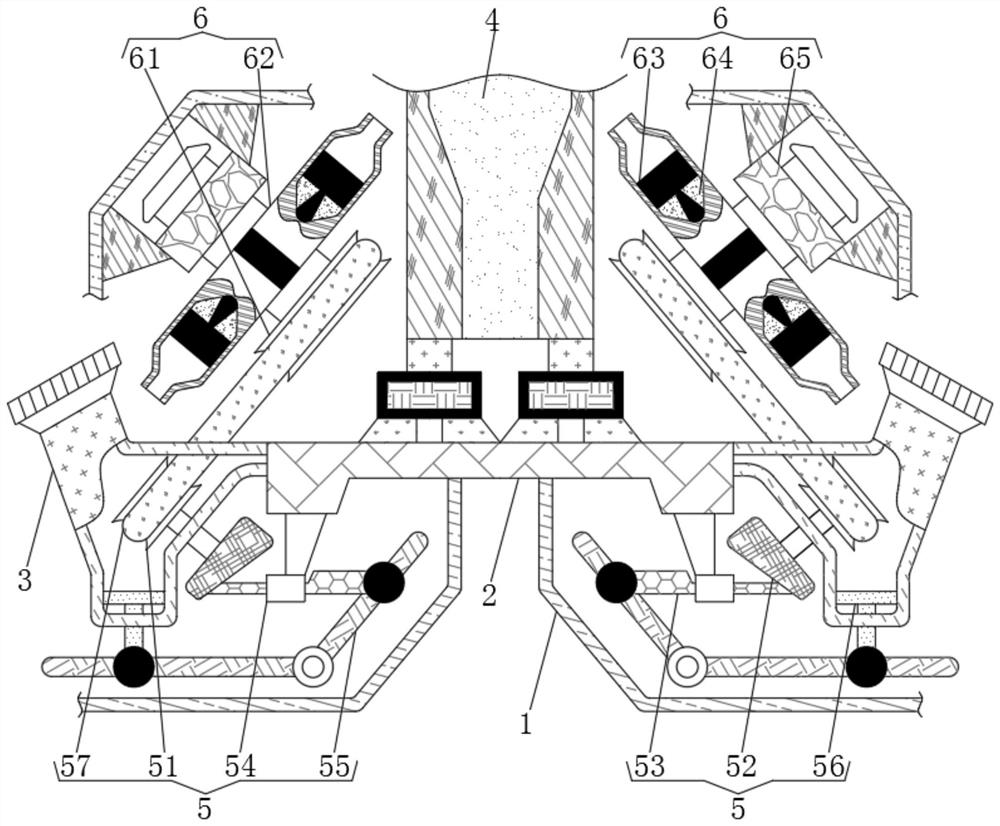

[0022] see Figure 1-3 , a dry-type transformer with high safety performance, including a casing 1, a support frame 2, an exhaust pipe 3, a main body 4, a cooling mechanism 5 and a heat transfer mechanism 6.

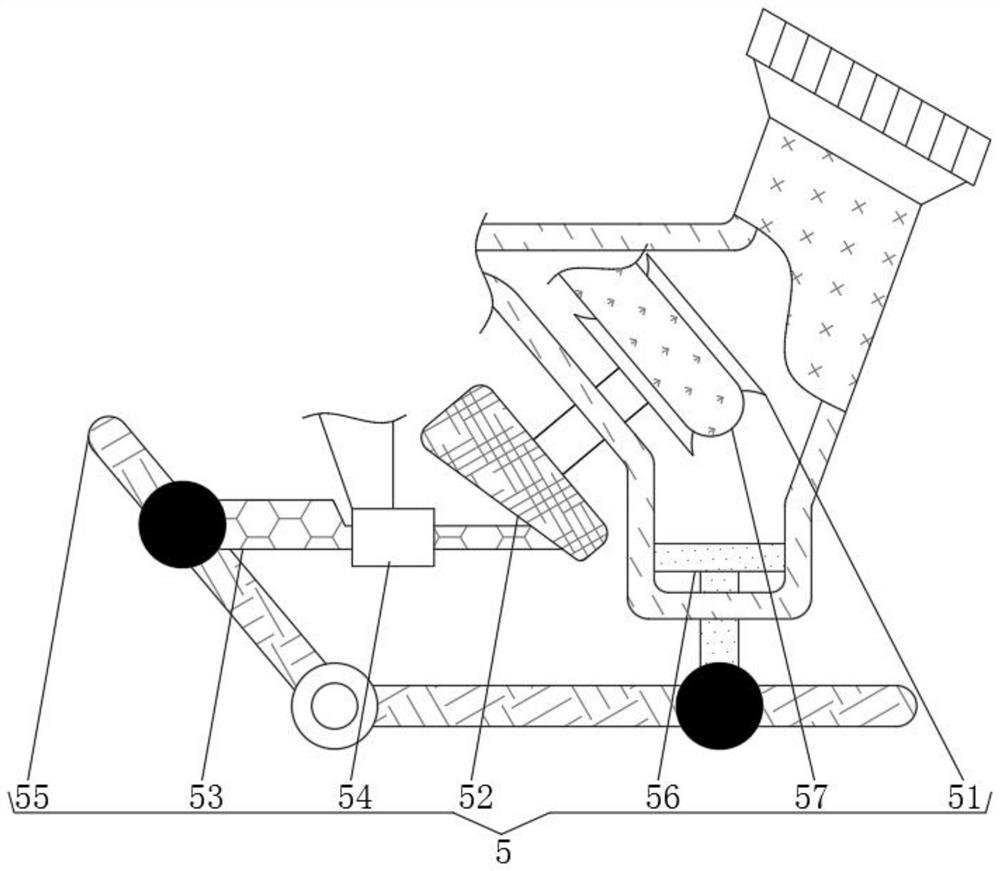

[0023] The cooling mechanism 5 includes a small turntable 51, a rotary column 52 is welded on the side of the small turntable 51, the outer side of the rotary column 52 is slidingly connected with a moving rod 53, the outer side of the moving rod 53 is sleeved with a limit tube 54, and the outer side of the moving rod 53 rotates A rotating rod group 55 is connected, the outer side of the rotating rod group 55 is slidably connected with a piston 56 , and the outer side of the small turntable 51 is rotatably connected with a heat absorption belt 57 .

[0024] There are two small turntables 51 with the same specifications. The two small turntables 51 are arranged in a figure-eight shape. The sides of the two small turntables 51 that are close to each other and below them ar...

Embodiment 2

[0027] see Figure 1-3 , a dry-type transformer with high safety performance, including a casing 1, a support frame 2, an exhaust pipe 3, a main body 4, a cooling mechanism 5 and a heat transfer mechanism 6.

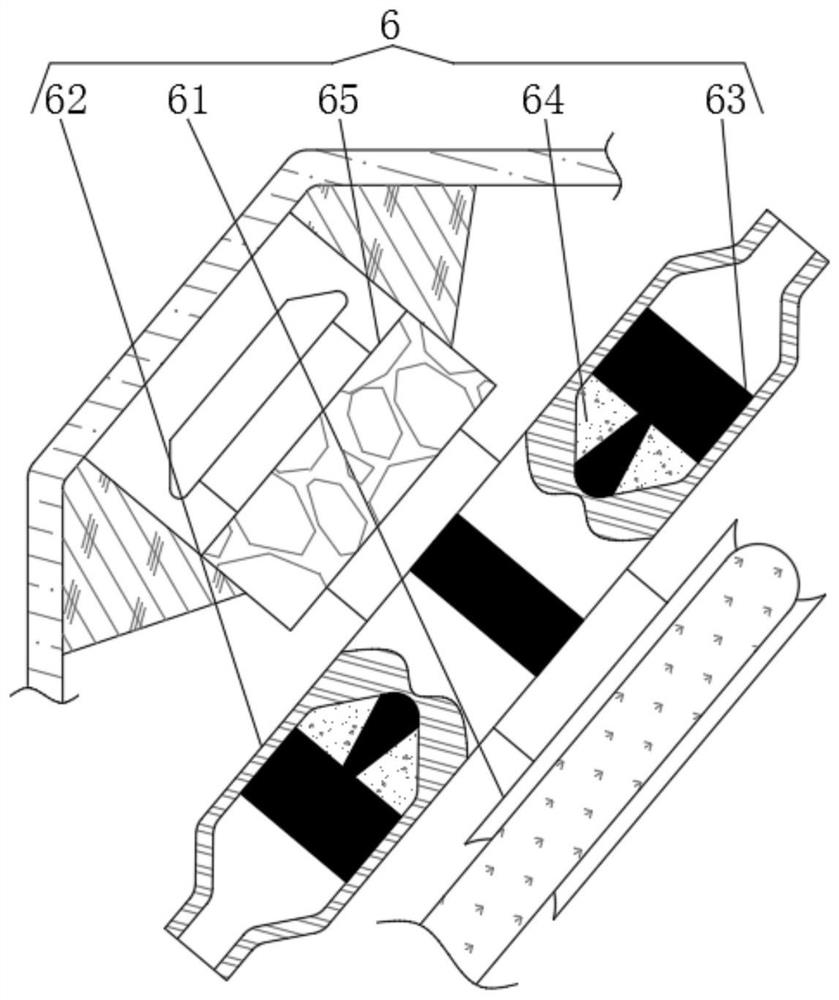

[0028] The heat transfer mechanism 6 includes a large turntable 61, a heat conduction block 62 is provided on the outside of the large turntable 61, and a counterweight 63 is slidably connected to the inside of the heat conduction block 62, and a low boiling point is provided on the outside of the counterweight 63 and inside the heat conduction block 62. The evaporating liquid 64 and the side of the heat conduction block 62 away from the large turntable 61 are provided with a fixing frame 65 .

[0029] There are two large turntables 61 with the same specifications. The two large turntables 61 are arranged in a figure-eight shape. The ends of the two large turntables 61 away from each other are provided with a rotating shaft. The outer side of the rotating shaft is sleeve...

Embodiment 3

[0032] see Figure 1-3 , a dry-type transformer with high safety performance, including a casing 1, a support frame 2, an exhaust pipe 3, a main body 4, a cooling mechanism 5 and a heat transfer mechanism 6.

[0033]The cooling mechanism 5 includes a small turntable 51, a rotary column 52 is welded on the side of the small turntable 51, the outer side of the rotary column 52 is slidingly connected with a moving rod 53, the outer side of the moving rod 53 is sleeved with a limit tube 54, and the outer side of the moving rod 53 rotates A rotating rod group 55 is connected, the outer side of the rotating rod group 55 is slidably connected with a piston 56 , and the outer side of the small turntable 51 is rotatably connected with a heat absorption belt 57 .

[0034] There are two small turntables 51 with the same specifications. The two small turntables 51 are arranged in a figure-eight shape. The sides of the two small turntables 51 that are close to each other and below them are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com