Biological flocculant as well as preparation method and application thereof

A technology of biological flocculants and uses, applied in the aforementioned biological flocculants and their preparation methods and uses, in the field of biological flocculants, to achieve the effect of good application effect and high flocculation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

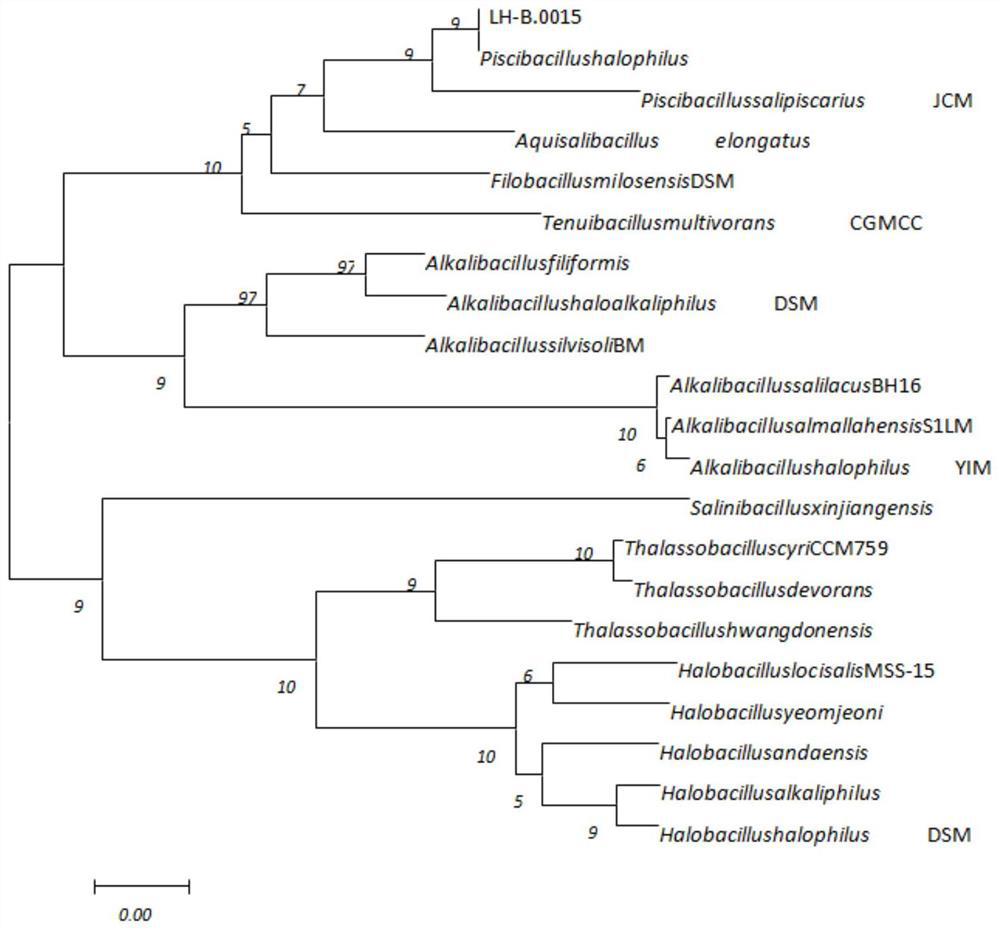

[0046] Example 1, Isolation and Preservation of Bacillus halophilus LH-B.0015

[0047] Bacillus halophilus LH-B.0015 was isolated from sea bottom mud.

[0048]Prepare LB liquid medium with a NaCl concentration of 20%, add 250 mg / L glycerol, 250 mg / L grape, and 50 mg / L methanol, and enrich the samples for 48 hours at 30°C. The strains in the enriched culture medium were isolated by using YL solid medium. 1L medium contains the following components: glucose: 0.6g, trisodium citrate 0.5g, glycerol 2mL, phenol 0.1g, aniline 0.05g, peptone 1.6g, dipotassium hydrogen phosphate 0.35g, potassium dihydrogen phosphate 0.1g, Ammonium sulfate 0.25g, ammonium chloride 0.25g, MgSO40.5g, CaCl2 0.1g, NaCl 180g; trace element solution 10mL, pH7.0-7.2; agar 2.5%.

[0049] Trace element solution (1000mL): MnCl 2 ·7H 2 O 0.03g, H 3 BO 3 0.03g, CoCl 2 ·6H 2 O 0.20g, CuCl 2 ·6H 2 O, NiCl 2 ·6H 2 O 0.02g, Na 2 Mo 4 2H 2 O 0.03g

[0050] The strain LH-B.0015 was deposited in the Gene...

Embodiment 2

[0051] Example 2, preparation of fermentation product of Bacillus halophilus LH-B.0015

[0052] (1) Culture medium: glucose 250mg / L, sucrose 500mg / L, glyceraldehyde 200mg / L, sodium chloride 100-250g / L, cellulose 100mg / L, starch 250mg / L, sodium acetate 250mg / L, ammonium sulfate 500mg / L, a small amount of trace elements, pH 7.0-9.0. The liquid medium is sterilized while controlling water evaporation.

[0053] (2) Put the above medium into a 1L Erlenmeyer flask, inoculate Bacillus halophilus LH-B.0015 and ferment at a temperature of 35°C and a salt concentration of 1%, 10%, 15%, 20%, and 25%. Cultivate, supplement the loss of water during the cultivation process, and prevent the change of salt concentration. After 48 hours of culture, the OD600 value was measured under the conditions of 1%, 10%, 15%, 20%, and 25% salt concentration, and the culture was transferred twice, and each transfer was cultured for 48 hours.

[0054] (3) Inoculate the culture solution in the 1L Erlenmey...

Embodiment 3

[0056] Embodiment 3, the preparation of biological flocculant

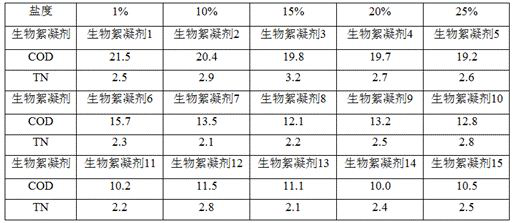

[0057] Get 70 parts of fermentation supernatants of 1%, 10%, 15%, 20%, 25% salinity Bacillus halophilus LH-B.0015 obtained in Example 2, add 15 parts of bentonite, diatomaceous earth 5 parts, ferrous sulfate 3 parts, magnesium carbonate 2 parts, calcium chloride 5 parts. After stirring and mixing, after spraying and drying at a temperature of 45-55° C., bioflocculant 1, bioflocculant 2, bioflocculant 3, bioflocculant 4, and bioflocculant 5 are obtained.

[0058] Get 80 parts of the fermentation supernatant of the 1%, 10%, 15%, 20%, 25% salinity Bacillus halophilus LH-B.0015 that embodiment 2 makes, add 10 parts of bentonite, diatomaceous earth 3 parts, 3 parts ferrous sulfate, 2 parts magnesium carbonate, 2 parts calcium chloride. After stirring and mixing, after spraying and drying at a temperature of 45-55° C., bioflocculant 6, bioflocculant 7, bioflocculant 8, bioflocculant 9, and bioflocculant 10 are obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com