Method and system for recovering CO in DMC synthesis tail gas through membrane separation

A synthesis tail gas and membrane separation technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of failure to take effective recovery methods, waste of effective gas CO, etc., and achieve no secondary pollution and CO recovery rate High, scalable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

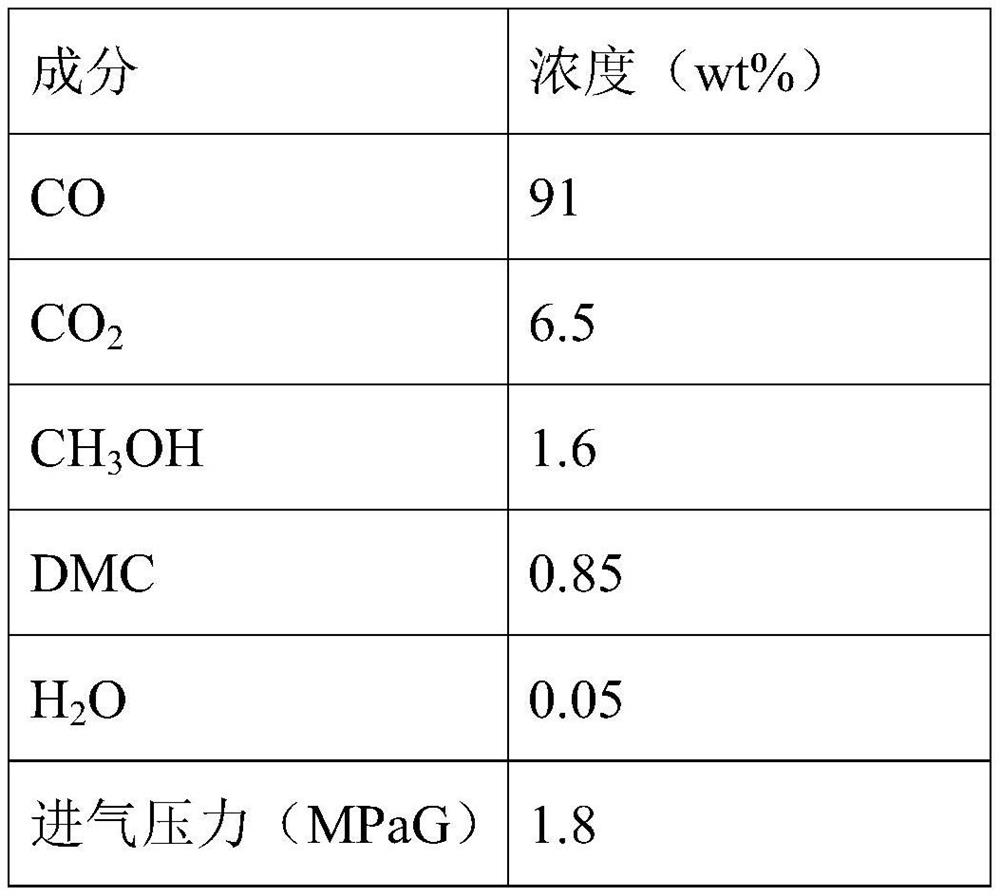

[0032] The composition and intake conditions of the DMC synthesis tail gas in this embodiment are shown in Table 1.

[0033] Table 1

[0034]

[0035]

[0036] This embodiment also discloses a method for membrane separation and recovery of CO in DMC synthesis tail gas. In this embodiment, the membrane module adopts a single-stage multi-module parallel connection method, including the following steps:

[0037] S1, the DMC synthesis tail gas in Table 1 is washed with water through a water washing tower, and methanol and DMC are removed therein to obtain a crude gas separation;

[0038] S2. After the crude separation gas is separated from the entrained water by the separator, it enters the air-gas heat exchanger and the low-temperature coarse separation gas at the outlet of the cold dryer for gas-gas heat exchange, reducing the temperature of the rough separation gas entering the cold dryer;

[0039] S3. After the gas-gas heat exchange, the crude fraction gas is cooled to ...

Embodiment 2

[0045] The composition and intake conditions of the DMC synthesis tail gas in this embodiment are shown in Table 2.

[0046] Table 2

[0047] Element Concentration (wt%) CO 91 CO 2

6.5 CH 3 Oh

1.6 DMC 0.85 h 2 o

0.05 Intake pressure (MPaG) 1.8 Intake temperature (°C) 50 Intake volume (Nm 3 / h)

1000

[0048] This embodiment also discloses a method for membrane separation and recovery of CO in DMC synthesis tail gas. In this embodiment, the membrane module adopts a two-stage multi-module series connection method, including the following steps:

[0049] S1, the DMC synthesis tail gas in table 2 is washed with water through a water washing tower, and methanol and DMC are removed therein to obtain a crude gas separation;

[0050] S2. After the crude separation gas is separated from the entrained water by the separator, it enters the air-gas heat exchanger and the low-temperature coarse separation gas a...

Embodiment 3

[0058] The composition and intake conditions of the DMC synthesis tail gas in this embodiment are shown in Table 3.

[0059] table 3

[0060] Element Concentration (wt%) CO 91 CO 2

6.5 CH 3 Oh

1.6 DMC 0.85 h 2 o

0.05 Intake pressure (MPaG) 2.4 Intake temperature (°C) 50 Intake volume (Nm 3 / h)

1000

[0061] This embodiment also discloses a method for membrane separation and recovery of CO in DMC synthesis tail gas. In this embodiment, the membrane module adopts a two-stage multi-module series connection method, including the following steps:

[0062] S1, the DMC synthesis tail gas in the table 3 is washed with water through a water washing tower, and methanol and DMC are removed therein to obtain a crude gas separation;

[0063] S2. After the crude separation gas is separated from the entrained water by the separator, it enters the air-gas heat exchanger and the low-temperature coarse separation g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com