Scraping-amplitude-adjustable sludge cleaning device for water conservancy project and method thereof

A water conservancy project and cleaning device technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the inconvenience of sludge salvage and treatment, affect the effect of sludge cleaning, and the inconvenience of adjusting the width of the scraper, etc. To solve the problem, to achieve convenient and fast salvage and treatment, improve cleaning effect and cleaning efficiency, and achieve flexible and changeable salvage and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

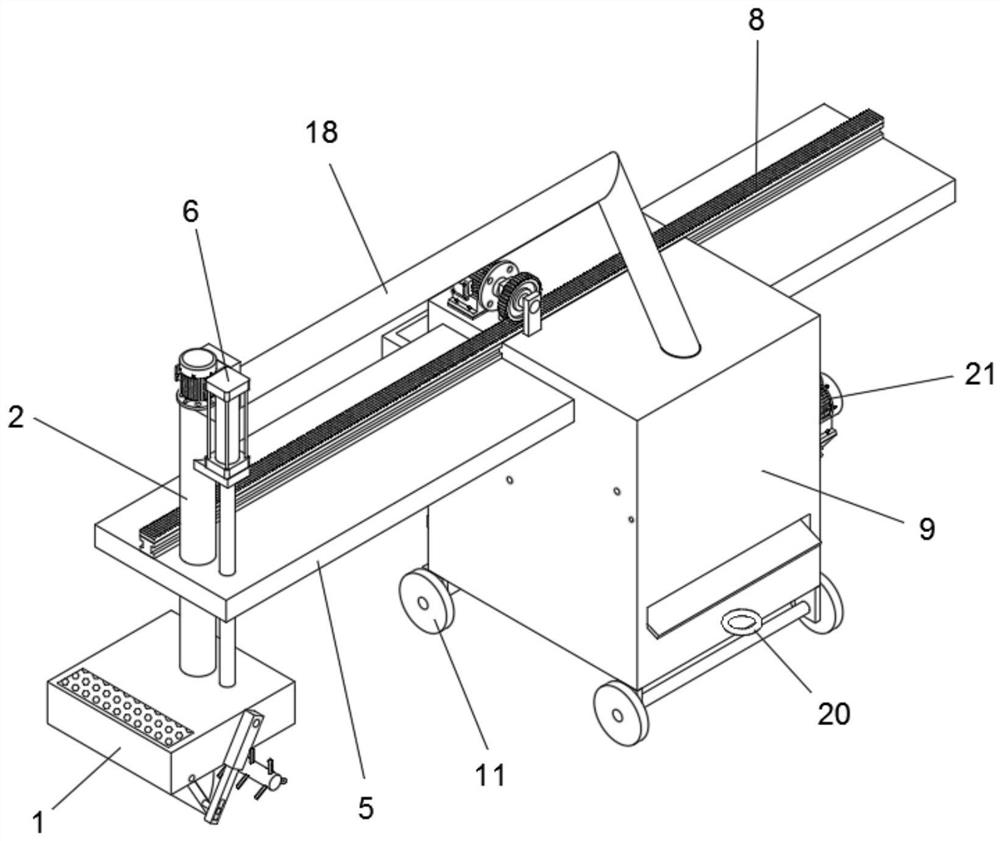

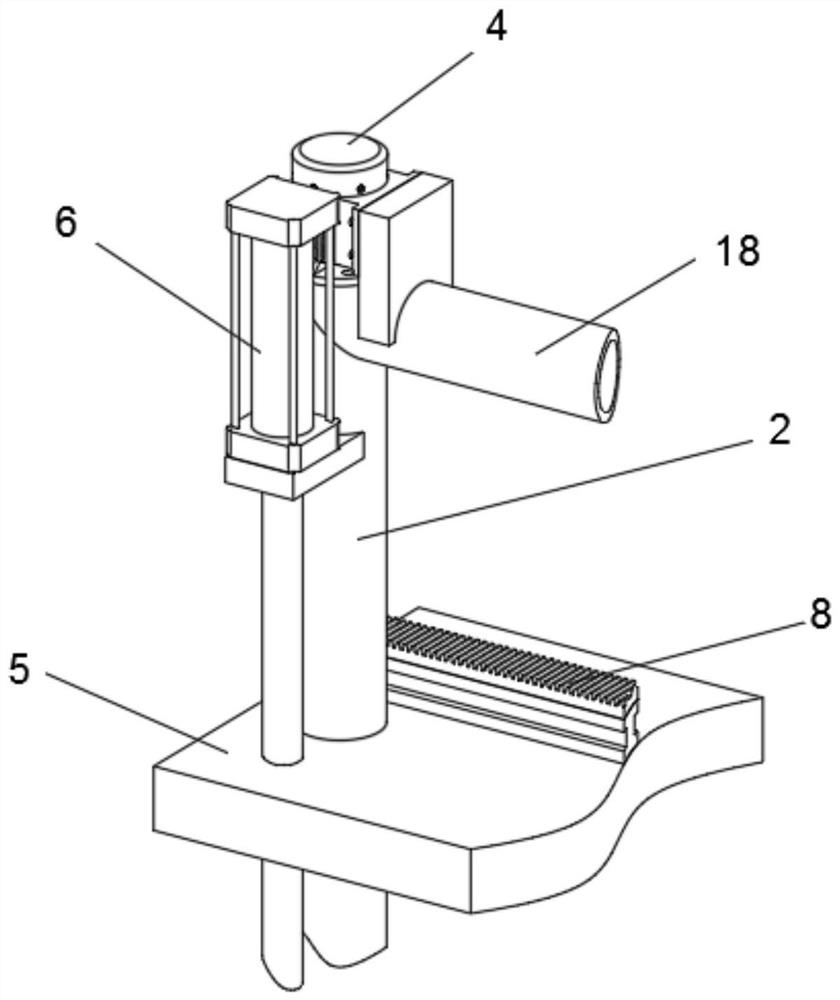

[0037] like Figure 1-4 As shown, a sludge cleaning device for water conservancy projects with adjustable scraping amplitude includes a scraping assembly 1, a conveying pipe 2 is fixed on the top surface of the scraping assembly 1, an auger 3 is arranged inside the conveying pipe 2, and a conveying pipe 2 The motor A4 is installed on the top surface through the mounting seat, the movable block 5 is set on the conveying pipe 2, the cylinder 6 is installed on the upper end of the front wall of the conveying pipe 2 through the mounting seat, the right end of the conveying pipe 2 is connected with a hose 18, and the top surface of the movable block 5 The rear end is fixedly provided with a fixed block 7, and the upper surface of the fixed block 7 is fixedly provided with a rack 8, and the right end of the movable block 5 is slidably connected with a box body 9, and the lower side of the box body 9 is provided with two round rods 10 in a front-back symmetrical structure. Two wheels...

Embodiment 2

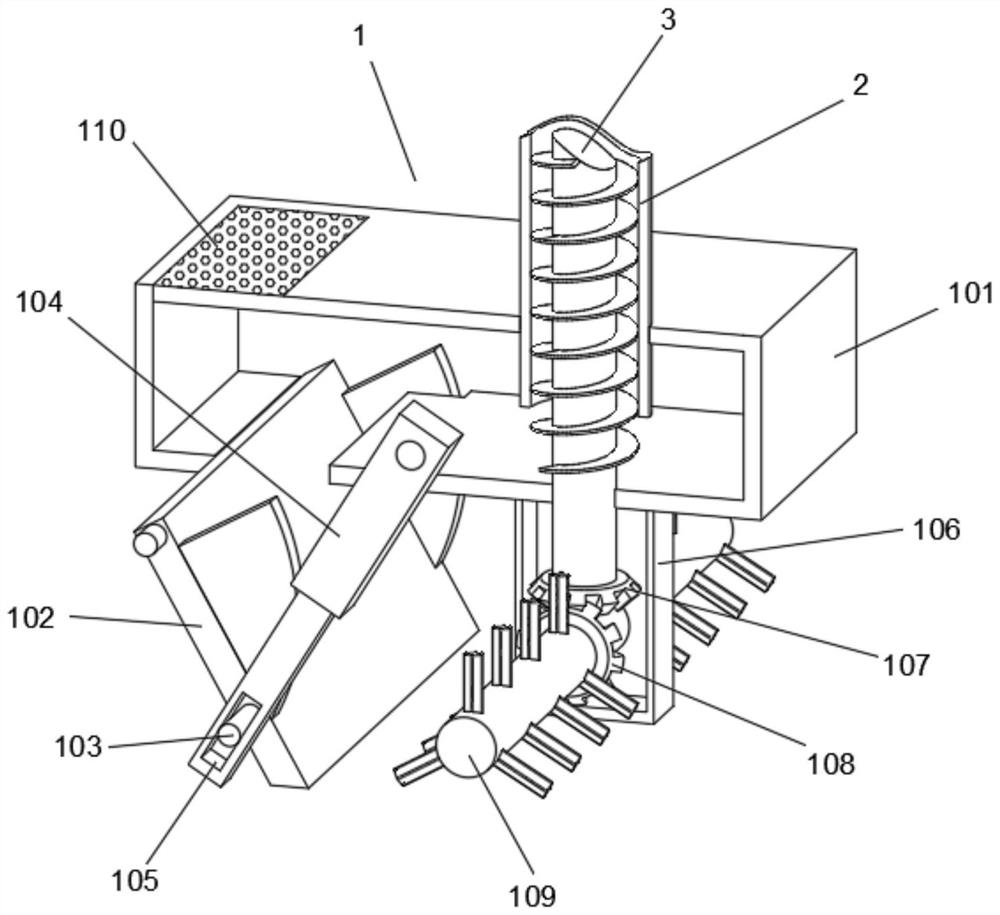

[0041] On the basis of Embodiment 1, the scraping assembly 1 includes a scraping box 101, the left end of the bottom surface of the scraping box 101 is rotatably connected to a scraper 102, the front surface of the scraper 102 is fixed with a rotating rod 103, and the front surface of the scraping box 101 rotates. Connected with an electric push rod 104, the front surface of the lower end of the electric push rod 104 is provided with a chute 105, the conveying pipe 2 extends through the outer wall of the scraping box 101 to the inside, and the middle part of the bottom surface of the scraping box 101 is fixed with a sealing box 106, and the auger 3 The lower end passes through the scraping box 101 and extends to the inside of the sealing box 106 and is fitted with a bevel gear A107. The lower end of the bevel gear A107 is meshed with a bevel gear B108, and the middle part of the bevel gear B108 is sleeved with a crushing roller 109. A water filter port 110 with a filter screen ...

Embodiment 3

[0044] like Figure 5-9 As shown, on the basis of Embodiment 2, a conveyor belt 901 is provided at the upper end of the box body 9, and a plurality of push blocks 902 are fixed on the conveyor belt 901 in an annular array structure. Teeth 903, the lower end of the conveyor belt 901 is provided with a screen 904, the lower end of the screen 904 is provided with an inclined block 905, and the upper end of the rear wall of the box body 9 is hung with a collecting tank 906.

[0045] The bottom surface of the push block 902 at the lower end is in frictional contact with the top surface of the screen cloth 904. The conveyor belt 901 and the screen cloth 904 are all inclined. The body 9 communicates with each other, the transmission gear 903 is rotationally connected with the casing 9, and the screen 904 and the inclined block 905 are connected and fixed with the inner wall of the casing 9.

[0046] The inner left end of the box body 9 is in a forward-backward symmetrical structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| void ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com