Carbon-supported iridium-molybdenum-tungsten intermetallic compound and preparation method and application thereof

A technology of intermetallic compounds, molybdenum and tungsten, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of lower reaction rate than acidic environment, slow kinetics, limited reserves, etc., and achieve good electrocatalytic activity and stability, The effect of improving utilization rate and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

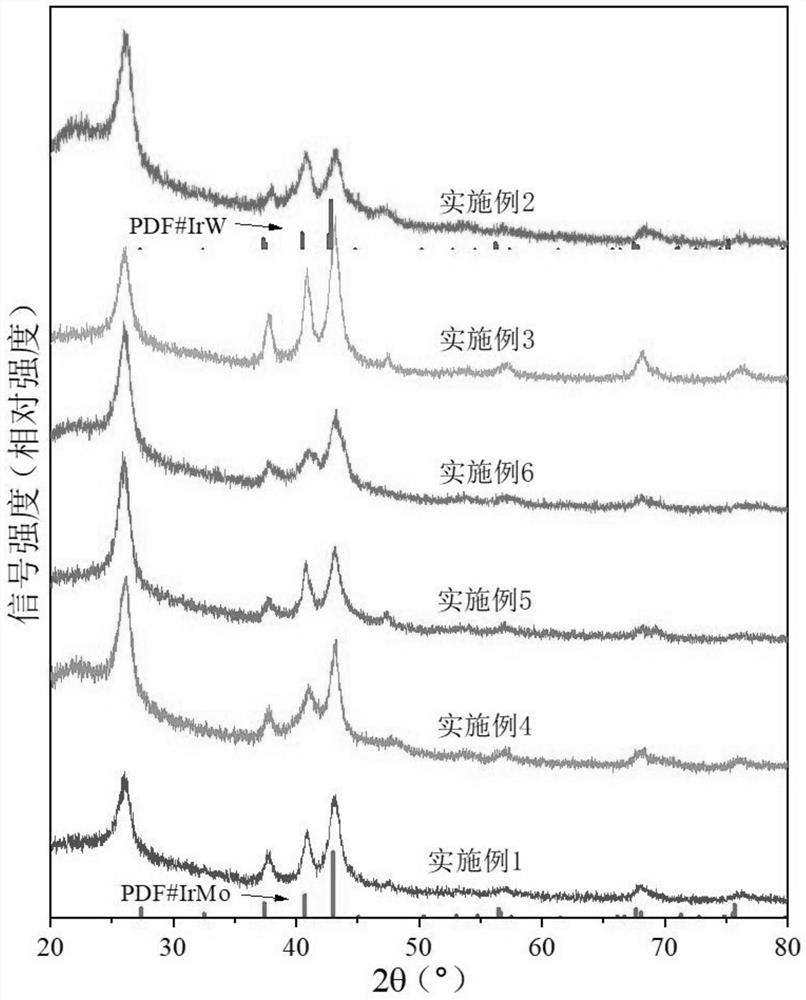

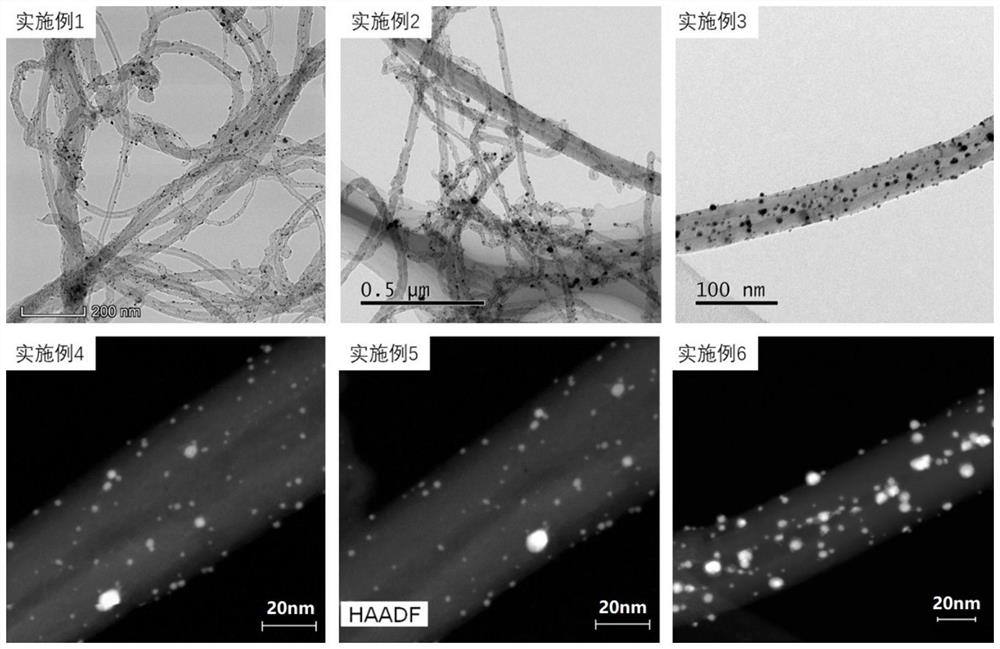

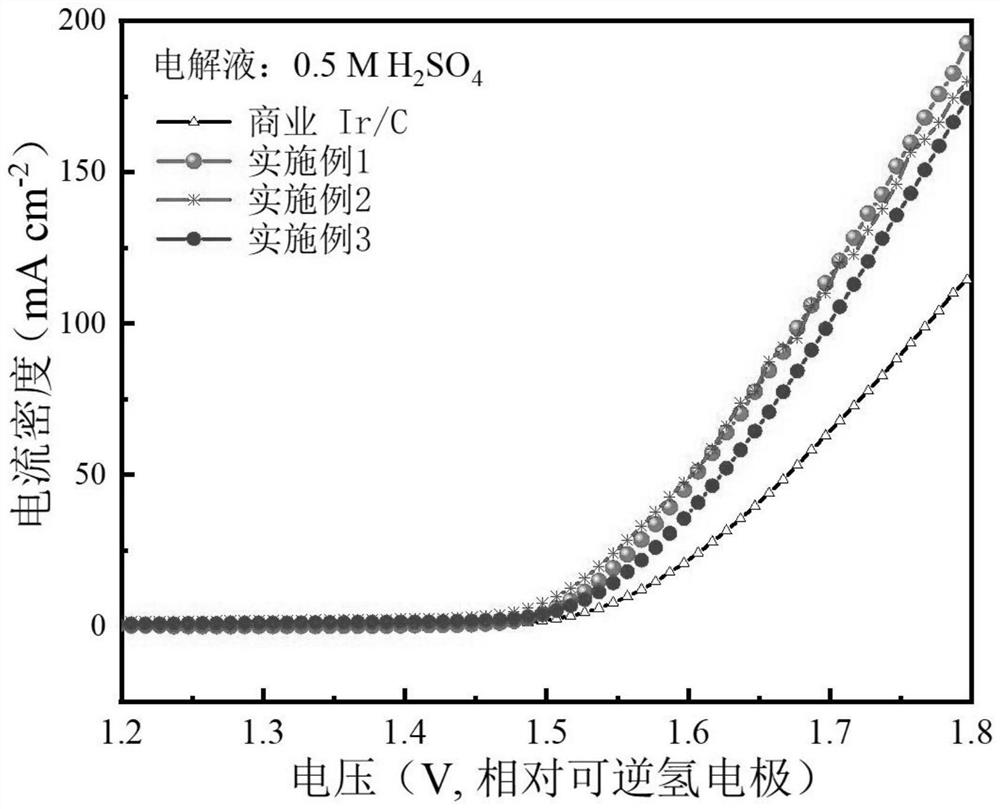

Embodiment 1

[0046] A carbon-supported iridium-molybdenum-tungsten intermetallic compound, the preparation method of which comprises the following steps:

[0047] 1) Add 4g of commercial carbon nanotubes to 400g of 10% nitric acid aqueous solution by mass fraction, then stir for 12h at 160°C and 300r / min, filter, wash the filtered solid 3 times, and then transfer to vacuum drying Dry in an oven at 100°C for 6 hours to obtain hydrophilic modified carbon nanotubes;

[0048] 2) the trihydrate iridium chloride solution of concentration 0.055mol / L, the tetrahydrate ammonium molybdate solution of concentration 0.055mol / L and the carbon nanotube of 80mg hydrophilic modification are mixed, make the total mass of iridium element and molybdenum element and The mass ratio of hydrophilic modified carbon nanotubes is 1:4, the molar ratio of iridium element and molybdenum element is 1:1, ultrasonication is performed for 3.5 hours, and the mixture obtained by ultrasonication is added to a freeze-drying d...

Embodiment 2

[0050] A carbon-supported iridium-molybdenum-tungsten intermetallic compound, the preparation method of which comprises the following steps:

[0051] 1) Add 4 g of commercial carbon nanotubes to 220 g of aqueous nitric acid solution with a mass fraction of 40%, then stir for 7 h at 110° C. and a rotation speed of 750 r / min, filter, wash the filtered solid with water for 3 times, and then transfer to vacuum drying Dry in an oven at 100°C for 6 hours to obtain hydrophilic modified carbon nanotubes;

[0052] 2) Mix the iridium chloride trihydrate solution with a concentration of 0.005mol / L, the ammonium tungstate tetrahydrate solution with a concentration of 0.005mol / L and 80mg of hydrophilic modified carbon nanotubes, so that the total mass of iridium and tungsten elements is equal to The mass ratio of hydrophilic modified carbon nanotubes is 1:9, the molar ratio of iridium element and tungsten element is 1:1, sonication for 0.5h, the mixture obtained by sonication is added to a...

Embodiment 3

[0054] A carbon-supported iridium-molybdenum-tungsten intermetallic compound, the preparation method of which comprises the following steps:

[0055] 1) Add 4g of commercial carbon nanotubes to 40g of aqueous nitric acid solution with a mass fraction of 70%, then stir for 2 hours at 60°C and a rotation speed of 1200r / min, filter, wash the filtered solid with water for 3 times, and then transfer to vacuum drying Dry in an oven at 100°C for 6 hours to obtain hydrophilic modified carbon nanotubes;

[0056] 2) The iridium chloride trihydrate solution with a concentration of 0.0225mol / L, the ammonium molybdate tetrahydrate solution with a concentration of 0.01125mol / L, the ammonium tungstate tetrahydrate solution with a concentration of 0.01125mol / L and 80mg of hydrophilic modified carbon nano The tubes are mixed so that the mass ratio of the total mass of iridium, molybdenum and tungsten to the hydrophilic modified carbon nanotube is 3:7, and the molar ratio of iridium, molybdenum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com