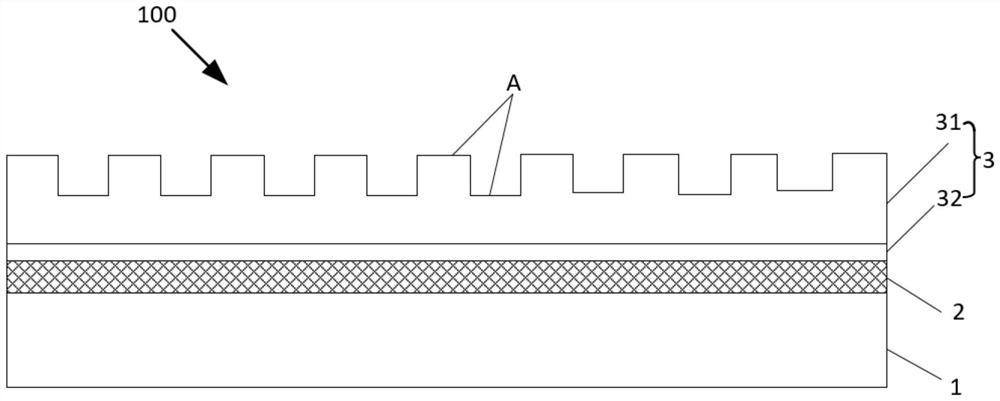

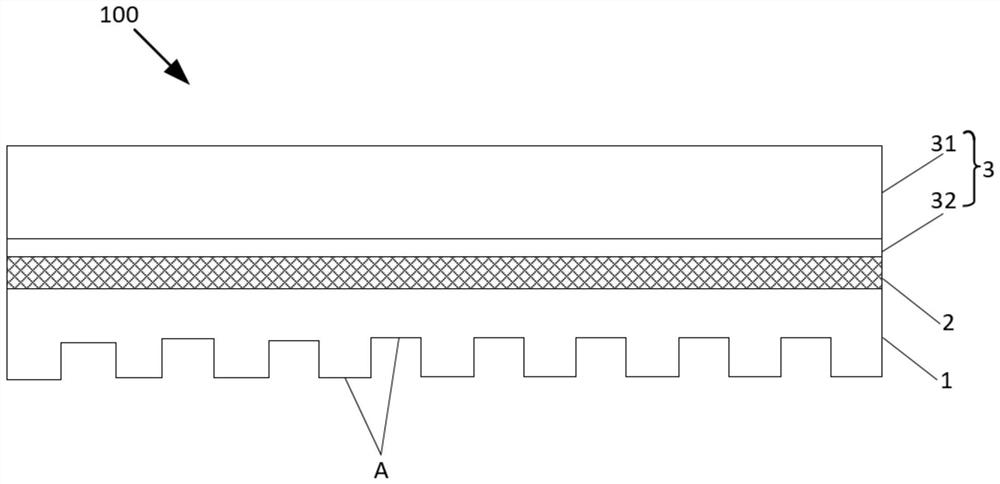

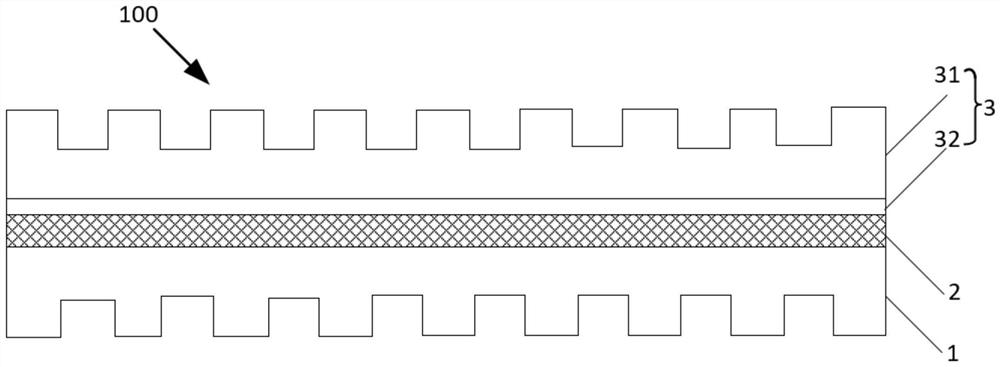

Adhesive tape and manufacturing method thereof

A manufacturing method and tape technology, which are applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve problems such as sheet adhesion, improve die-cutting efficiency and yield, avoid The effect of sheet adhesion and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the description of the present application, "plurality" means at least two, such as two, three, etc., unless otherwise specifically defined. All directional indications (such as up, down, left, right, front, back, top, bottom...) in the embodiments of the present application are only used to explain the relationship between the components in a certain posture (as shown in the accompanying drawings) If the specific posture changes, the directional indication will also change accordingly. Furthermore, the terms "include" and "have", as well as any variations thereof, are intended to cover a non-exclusive inclusion. For example, a process, method, system, product or device comprising a series of steps or units is not limited to the listed steps or units, but optionally also includes unlisted steps or units, or optionally further includes For other steps or units inherent in these processes, methods, products or apparatuses.

[0030] Additionally, reference herein to "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com