Warm-mixing rubber asphalt warm-mixing agent as well as preparation method and application thereof

A technology of rubber asphalt and warm mix agent, applied in the field of warm mix rubber asphalt, can solve the problems of equipment corrosion and affect the formation speed of the strength of the mixture, and achieve the effects of slowing down corrosion, improving road performance, and enhancing high and low temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

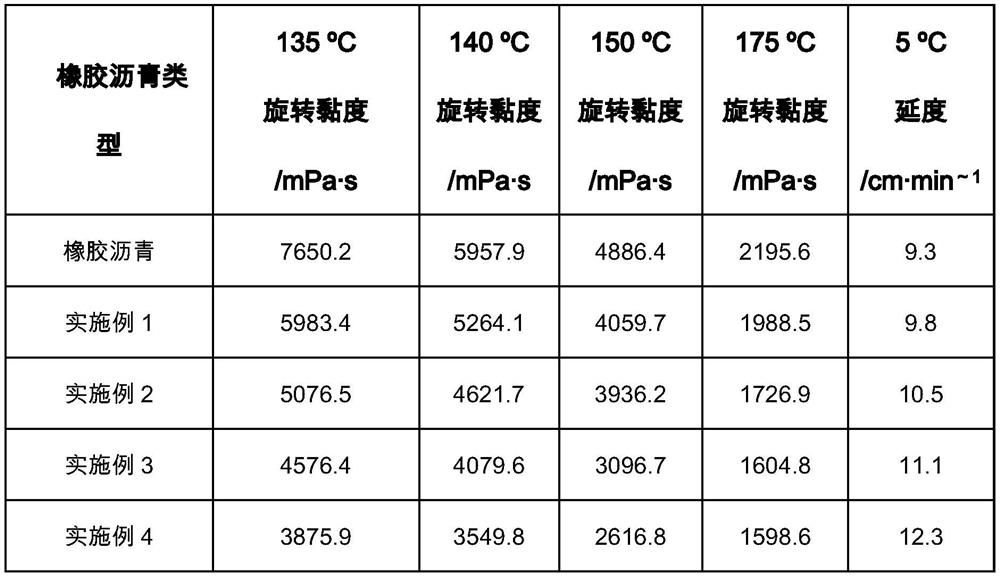

Examples

preparation example Construction

[0019] The preparation method of above-mentioned warm mixing agent may further comprise the steps:

[0020] (1) Add 100 parts of distilled water into the container, then stir and heat to 50℃~70℃;

[0021] (2) Add 2 to 22 parts of sodium lauryl sulfate, 1 to 16 parts of cetyltrimethylammonium bromide, and 5 to 25 parts of amphoteric imidazoline surfactants to the distilled water in step (1). 16-32 parts of myristic acid, 8-32 parts of sodium fatty alcohol ether sulfate, 4-24 parts of linolenic acid;

[0022] (3) Stir the mixture in step (2) uniformly for 10-20 minutes to obtain the warm mixing agent.

[0023] The application of the above-mentioned warm mix agent is to add it to asphalt to prepare warm mix asphalt. Specifically, when the warm mix agent is directly mixed into rubber asphalt for production, the mass fraction of the warm mix agent added is the base asphalt in rubber asphalt 2% to 4% of the mass.

Embodiment 1

[0025] Preparation method and application of warm-mix rubber asphalt warm-mix agent. The preparation steps of the warm mixing agent include: adding 100 parts of distilled water into the container, then stirring and heating to 50°C, then sequentially adding 10 parts of sodium lauryl sulfate, hexadecyl trimethyl 15 parts of ammonium bromide, 20 parts of amphoteric imidazoline surfactant, 25 parts of myristic acid, 10 parts of fatty alcohol ether sodium sulfate, and 20 parts of linolenic acid. Stir the above mixture uniformly for 10 minutes to obtain the warm mixing agent. Then, the prepared warm mix agent was mixed into the rubber asphalt, the blending mass of the warm mix agent was 2% of the base asphalt mass in the rubber asphalt, and the warm mix rubber asphalt was obtained after stirring at 140°C for 15 minutes.

Embodiment 2

[0027] Preparation method and application of warm-mix rubber asphalt warm-mix agent. The preparation steps of the warm mixing agent include: adding 100 parts of distilled water into the container, then stirring and heating to 60°C, then sequentially adding 15 parts of sodium lauryl sulfate, hexadecyl trimethyl 10 parts of ammonium bromide, 15 parts of amphoteric imidazoline surfactant, 30 parts of myristic acid, 15 parts of fatty alcohol ether sodium sulfate, and 15 parts of linolenic acid. Stir the above mixture uniformly for 15 minutes to obtain the warm mixing agent. Then, the prepared warm mix agent was mixed into the rubber asphalt, the blending quality of the warm mix agent was 2.5% of the mass of the base asphalt in the rubber asphalt, and the warm mix rubber asphalt was obtained after stirring at 150° C. for 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com