Bioelectrochemical device and method for mineralizing and degrading organic chlorine

A bioelectrochemical and organochlorine technology, applied in chemical instruments and methods, electrochemical biocombination treatment, biological water/sewage treatment, etc. Achieve complete degradation, reduce environmental toxicity, and shorten the degradation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A bioelectrochemical method for organic chlorine mineralization degradation, comprising the steps of:

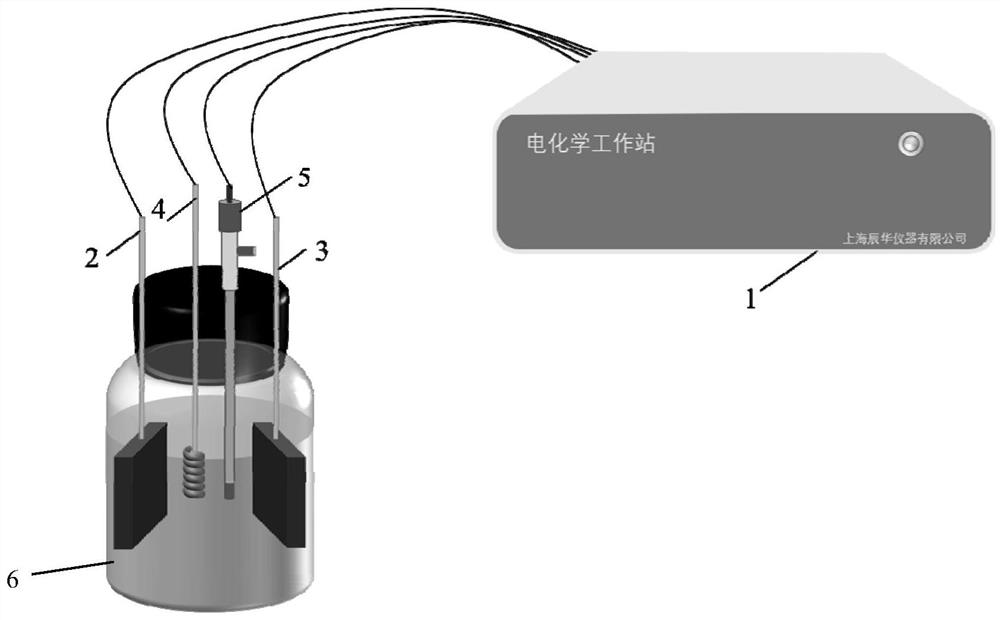

[0043] (1) Construct a bioelectrochemical device for mineralization and degradation of organochlorine

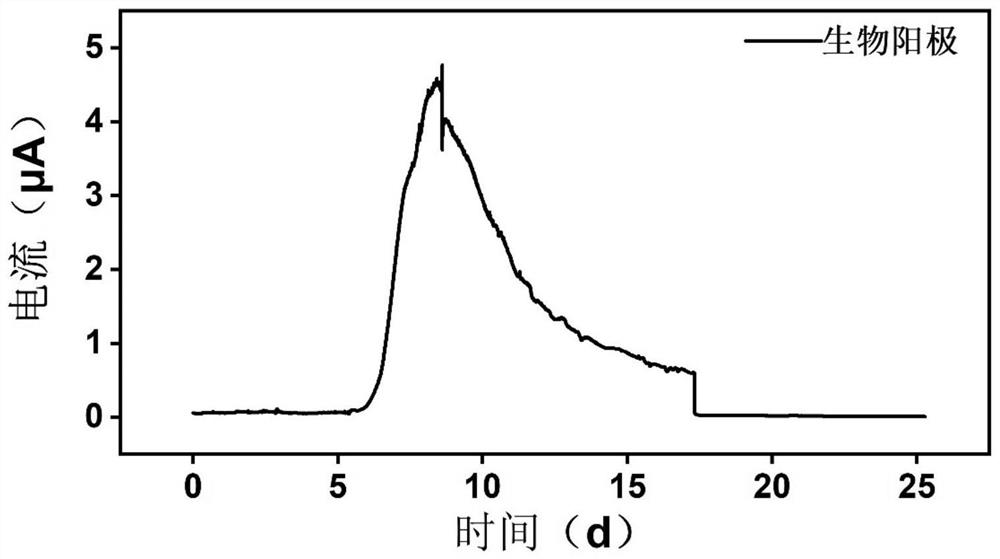

[0044] A 120mL serum bottle was used to construct a single-chamber bioelectrochemical reaction chamber, and a 7cm 2 carbon cloth, titanium wire and saturated calomel electrode (SCE) as working electrode, counter electrode and reference electrode (such as figure 1 shown). There are two working electrodes, and the constant potentials of the cathode and anode are controlled by a multi-channel constant potential controller to be -500mV and +200mV vs. SCE;

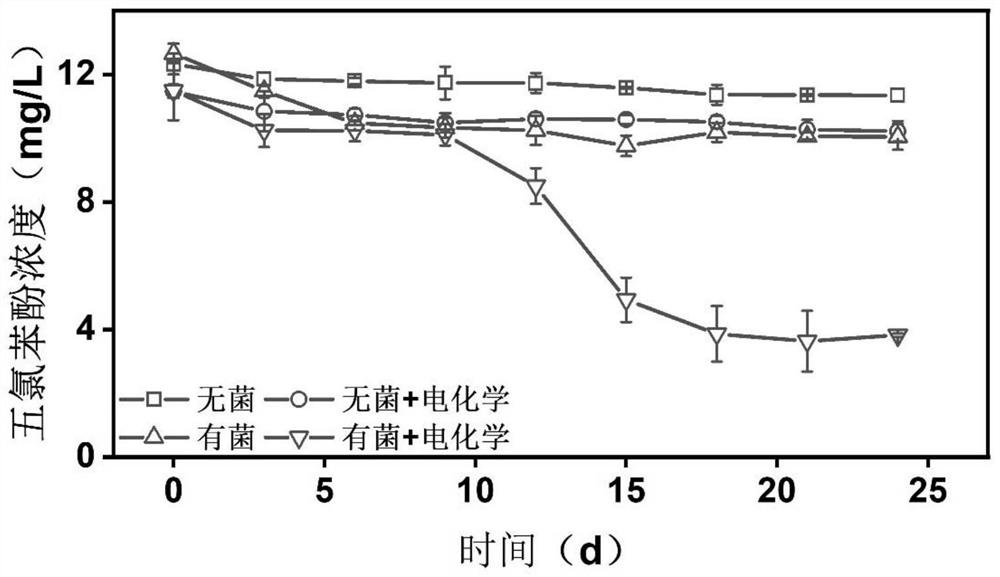

[0045] (2) Polluted water body and operating parameters

[0046] Sewage with an initial PCP concentration of about 12mg / L was inoculated in a bioelectrochemical reaction chamber for degradation experiments, and incubated at room temperature (25-28°C) in the dark. This treatment is abbreviated as "bacteria + electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com