Preparation method of special blade for cigar scissors or cigar knife and blade

A technology for cigar cutters and cigar cutters, applied in applications, tobacco, pipes, etc., can solve the problems of user experience affecting the overall quality of cigar cutters, high blade replacement frequency, and high use costs, and achieve overall quality improvement, low affinity, and high cost. Infrequent replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] 1.1 Preparation of cemented carbide materials

[0080] 1.1.1 Raw materials

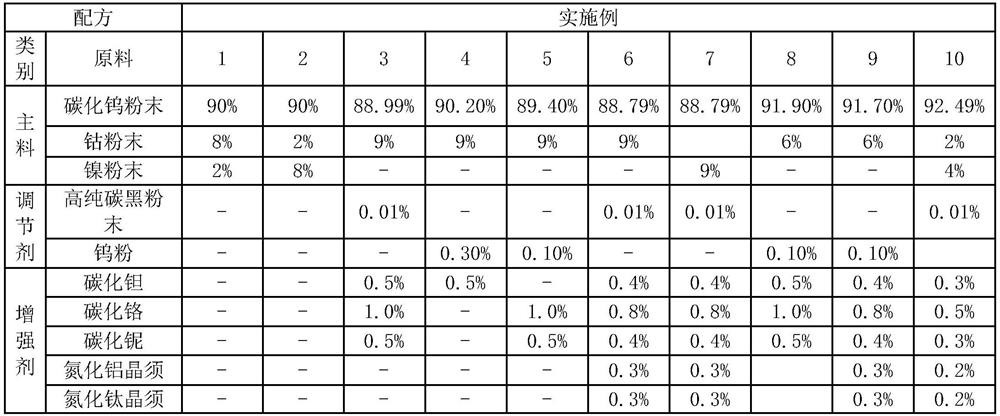

[0081] The ratio of raw materials is shown in Table 1.

[0082] 1.1.2 Preparation method

[0083] Include the following steps:

[0084] (1) mixing: mixing each raw material according to the proportioning ratio to obtain a homogeneous mixture;

[0085] Adopt ball mill to carry out wet ball milling, ball milling time is 90 hours, add molding agent during ball milling, molding agent adopts paraffin, the adding amount of molding agent is 1.5% of raw material gross weight; Ball milling medium is hexane, and the addition amount of ball milling medium is raw material 30% of the weight; the grinding ball used is a grinding rod, and its consumption is 3 times of the total weight of the raw material;

[0086] (2) dry granulation: dry and granulate the mixture obtained in step (1) to obtain powder;

[0087] Granulation by spray drying: the drying medium is high-temperature nitrogen, the oxygen conten...

Embodiment 2

[0103] 2.1 Preparation of cemented carbide materials

[0104] 2.1.1 Raw materials

[0105] The ratio of raw materials is shown in Table 1.

[0106] 2.1.2 Preparation method

[0107] Include the following steps:

[0108] (1) mixing: mixing each raw material according to the proportioning ratio to obtain a homogeneous mixture;

[0109] Use a ball mill to carry out wet ball milling, the ball milling time is 60 hours, add a molding agent during the ball milling, the molding agent is PEG, and the amount of molding agent added is 2% of the total weight of the raw materials; the ball milling medium is ethanol, and the amount of the ball milling medium is the weight of the raw material 40% of that; the grinding balls used are cemented carbide balls, the amount of which is 4 times the total weight of raw materials;

[0110] (2) dry granulation: dry and granulate the mixture obtained in step (1) to obtain powder;

[0111] Spray drying granulation: the drying medium is high-temperat...

Embodiment 3

[0127] 3.1 Preparation of cemented carbide materials

[0128] 3.1.1 Raw materials

[0129] The ratio of raw materials is shown in Table 1.

[0130] 3.1.2 Preparation method

[0131] Include the following steps:

[0132] (1) mixing: mixing each raw material according to the proportioning ratio to obtain a homogeneous mixture;

[0133] Adopt ball mill to carry out wet ball milling, ball milling time is 30 hours, add molding agent during ball milling, molding agent adopts paraffin, the adding amount of molding agent is 3% of raw material gross weight; Ball milling medium is ethanol, and the addition amount of ball milling medium is raw material weight 30% of that; the grinding balls used are cemented carbide balls, and the amount used is 3 times the total weight of raw materials;

[0134] (2) dry granulation: dry and granulate the mixture obtained in step (1) to obtain powder;

[0135] Spray drying granulation: the drying medium is high-temperature nitrogen to ensure that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com