Production process of arc-shaped aluminum hoop

A production process, arc-shaped technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems affecting the production cost of enterprises, unstable casting quality, poor mechanical properties, etc., to achieve good quality , Optimizing the microstructure, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

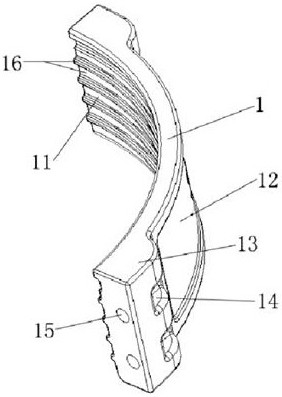

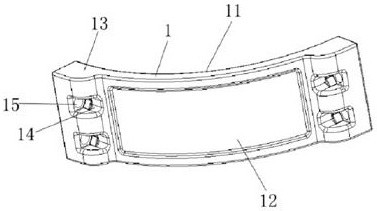

[0033] Such as figure 1 and figure 2 As shown, an arc-shaped aluminum hoop includes a hoop body 1. The hoop body 1 is integrally formed by forging aluminum material through a forging process. The hoop body is an arc of a quarter circle, which is divided into The inner arc surface 11 and the outer arc surface 12, the two sides of the outer arc surface 12 of the hoop body 1 are integrally provided with connecting protrusions 13, and the connecting protrusions 13 are provided with grooves 14, and the grooves 14 are A connection hole 15 is provided, and the inner arc surface 11 of the hoop body 1 is a concave-convex structure 16 . The four hoop bodies 1 are synthesized into an integral ring and then sleeved on the outside of the pipeline, and the adjacent hoop bodies 1 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com