Magnesium alloy plate strip different-temperature different-speed coordinated rolling device and application

A magnesium alloy plate and isothermal technology, which is applied in the driving device of metal rolling mill, metal rolling, metal rolling, etc., can solve the problem of difficult to achieve continuous production, difficult to control the flatness of plate shape, damage to the rolling mill, etc. The problem is to improve the bending problem of the plate shape, the design of the device is simple and ingenious, and the effect of improving the edge cracking of the strip rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

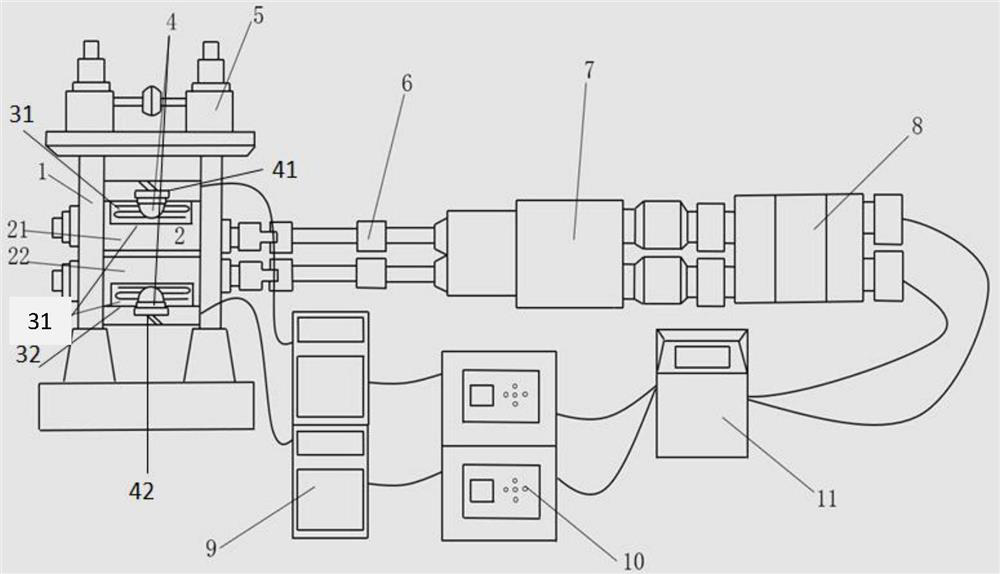

[0032] Embodiment one, as figure 1 Shown is a coordinated rolling device for magnesium alloy plates and strips at different temperatures and speeds. The device includes a roll 2, a frame 1, a roll induction heating system and a roll speed adjustment system; The upper induction coil 31 and the upper temperature measuring probe 41 on the periphery, and the lower induction coil 31 and the lower temperature measuring probe 41 arranged on the periphery of the lower roll 22; the upper and lower induction coils are electrically connected to the heating system console 10 respectively; The above-mentioned induction coil is a U-shaped induction coil, which is half surrounded by the outer circumference of the roll. The roll speed adjustment system includes a motor 8, a reducer 7, and a shaft coupling 6 that are electrically connected in sequence; the motor 8, the reducer 7, and the shaft coupling 6 are provided with two groups, which are respectively connected with the upper and lower ro...

Embodiment 2

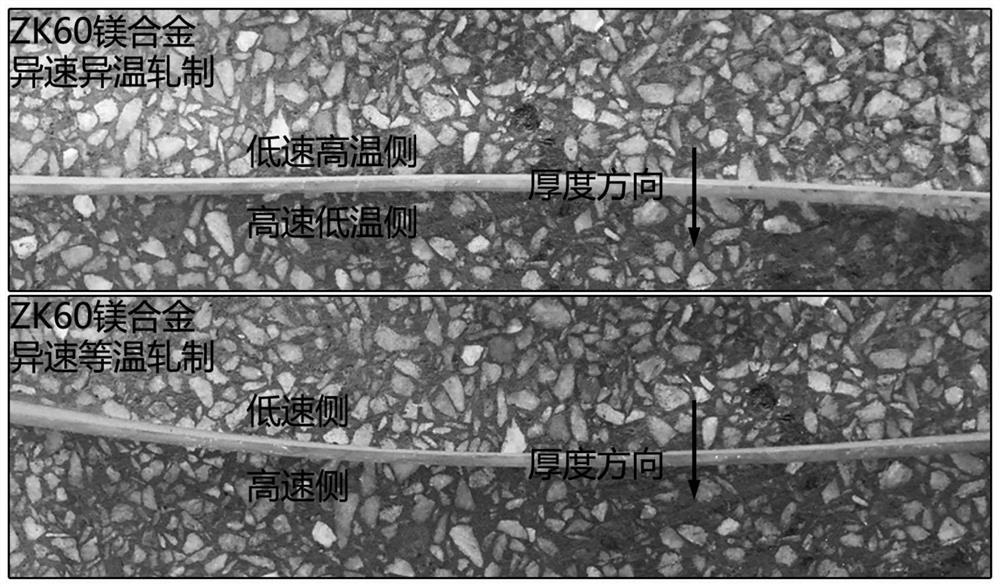

[0034]Taking ZK60 as an example, the bending degree and microstructure properties of the plates obtained by rolling deformation using the device and process method of the present invention were compared with those obtained without using the device and process method of the present invention.

[0035] Test 1: use device and technique of the present invention, concrete steps are as follows:

[0036] 1) Turn on the induction heating of the upper and lower rolls, preheat the temperature of the upper roll to 100°C, and preheat the temperature of the lower roll to 300°C, so that the temperature ratio of the upper and lower rolls is 1:3;

[0037] 2) Set the speed of the upper roll to 10m / min, and the speed of the lower roll to 5m / min, so that the speed ratio of the upper and lower rolls is 2:1;

[0038] 3) Preheat the 20mm thick ZK60 sheet to 300°C and keep it for 30min;

[0039] 4) The diameter of the roll is 350mm, and the deformation is 50%; rolling is carried out.

[0040] Comp...

Embodiment 3

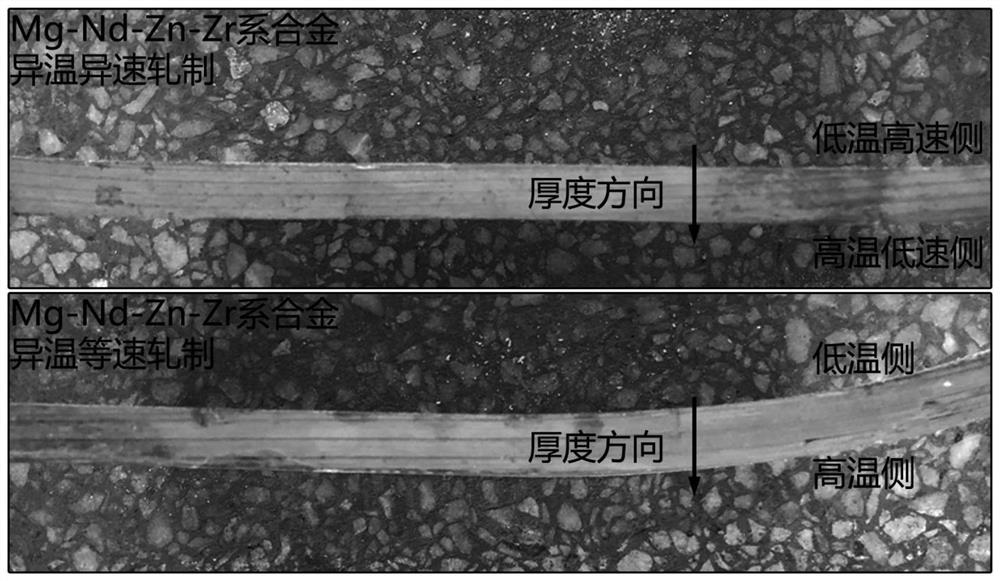

[0047] Taking the Mg-Nd-Zn-Zr alloy as an example, the plate shape bending and microstructure properties of the plates obtained by rolling deformation using the device and process method of the present invention are compared with those obtained without the device and process method of the present invention.

[0048] Test 2: use device and technique of the present invention, concrete steps are as follows:

[0049] 1) Turn on the induction heating of the upper and lower rolls, preheat the temperature of the upper roll to 250°C, and preheat the temperature of the lower roll to 450°C, so that the temperature ratio of the upper and lower rolls is 1:1.8;

[0050] 2) Set the speed of the upper roll to 10m / min, and the speed of the lower roll to 5m / min, so that the speed ratio of the upper and lower rolls is 2:1;

[0051] 3) Preheat the 25mm thick ZK60 sheet to 450°C and keep it for 50min;

[0052] 4) The diameter of the roll is 350mm, and the deformation is 40%; rolling is carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com