Method for forming linear groove and method for manufacturing grain-oriented electrical steel sheet

A linear, steel plate technology, applied in the direction of manufacturing tools, circuits, magnetic objects, etc., can solve the problems of deterioration of magnetic properties, white point interruption, etc., to achieve excellent magnetic flux density, suppress the deterioration of magnetic flux density, and reduce iron loss. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

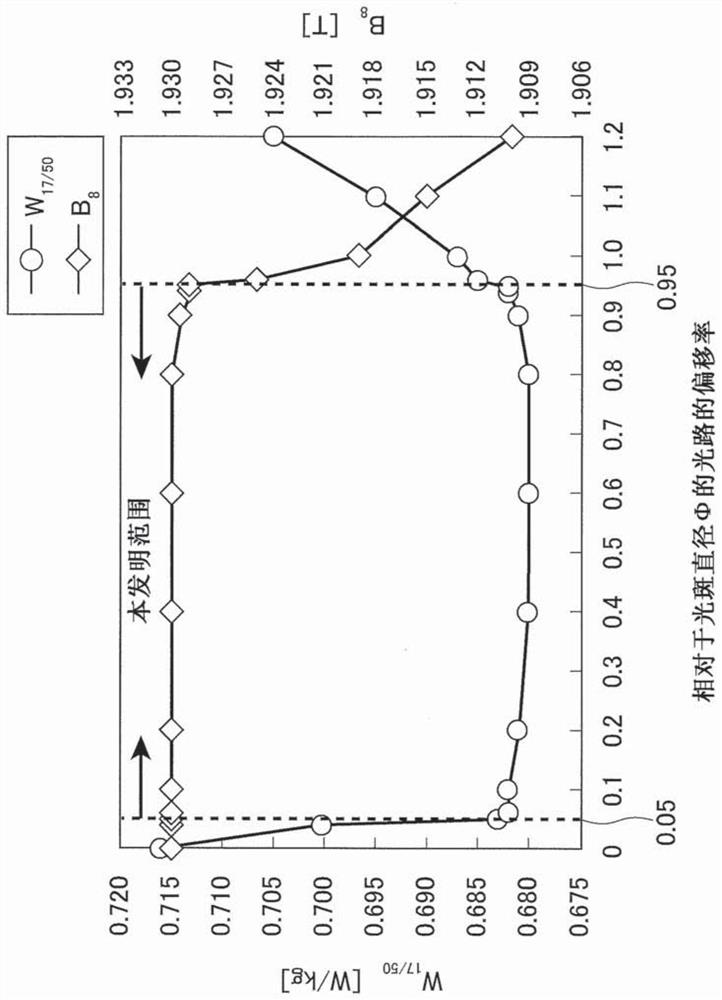

[0122] Hereinafter, the present invention will be specifically described based on examples. The following examples show preferred examples of the present invention, and the present invention is not limited to these examples at all. It is also possible to implement changes within the range that can conform to the gist of the present invention, and such forms are also included in the technical scope of the present invention.

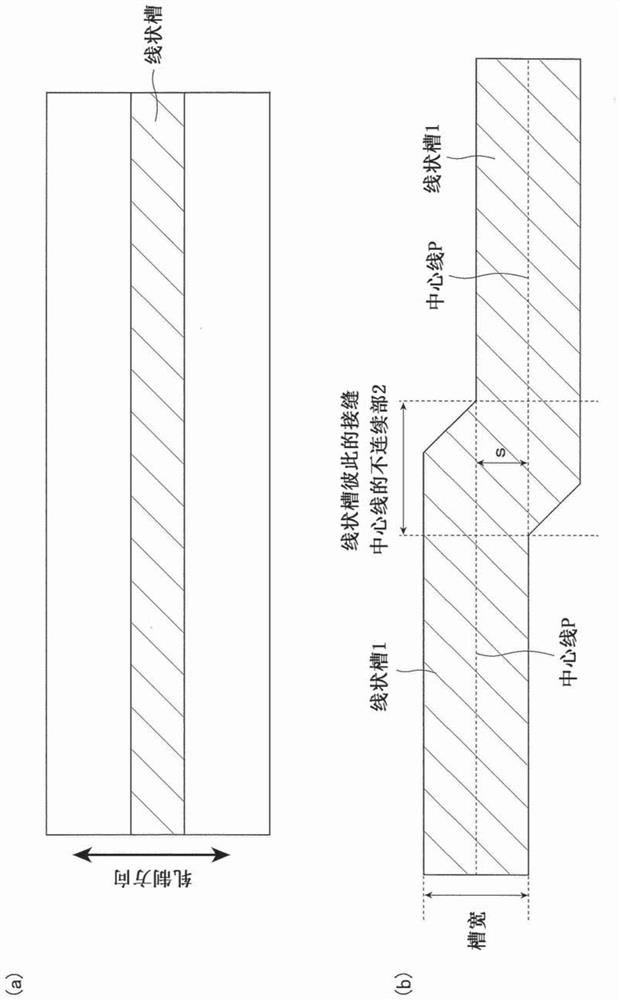

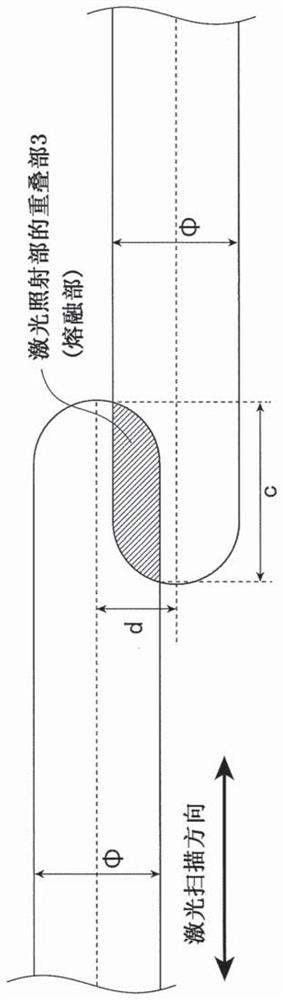

[0123] A steel material (slab) of a grain-oriented electrical steel sheet having the composition system shown in Table 2 with the balance being Fe and unavoidable impurities was hot-rolled and hot-rolled sheet annealed. Thereafter, cold rolling was performed twice with intermediate annealing interposed therebetween to obtain a cold-rolled steel strip having a thickness of 0.23 mm. After the resist ink was applied to the entire surface of the cold-rolled steel strip to form a resist film, the resist film was removed using two laser beams irradiated by two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com