Treatment solution for insulating coating, grain-oriented electrical steel sheet with insulating coating, and manufacturing method thereof

A technology of insulating film and electromagnetic steel plate, applied in the direction of pretreatment surface, device for coating liquid on the surface, circuit, etc., can solve problems such as poor appearance and iron loss reduction, and achieve excellent iron loss reduction effect and excellent moisture absorption resistance , the effect of suppressing the appearance of bad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

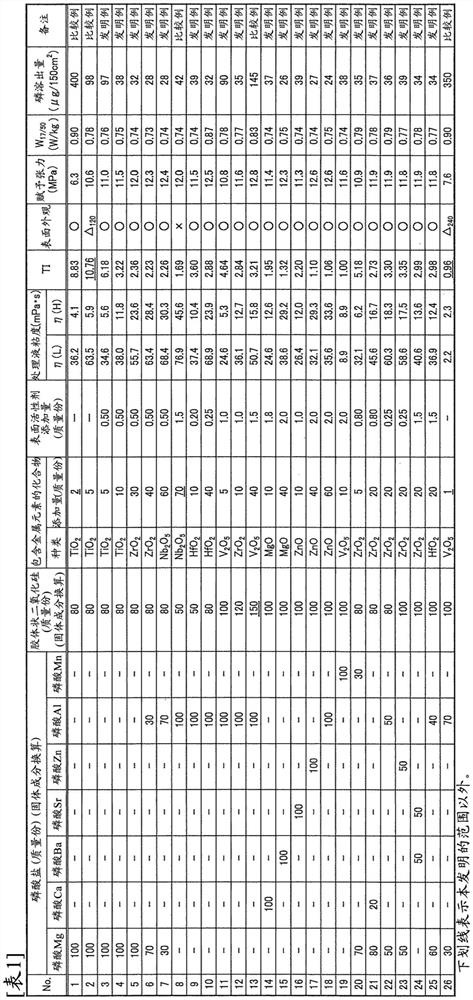

Embodiment 1

[0088] A finish-annealed grain-oriented electrical steel sheet having a thickness of 0.20 mm was prepared. The magnetic flux density B of the grain-oriented electrical steel sheet 8 It is 1.920T. After phosphoric acid pickling was carried out on this grain-oriented electrical steel sheet, the total of both sides after sintering was 8.0 g / m 2 Various chromium-free insulating coating treatment solutions described in Table 1 were applied in the same manner. At this time, the grain-oriented electrical steel sheet was conveyed using a roll coater at two levels of conveying speeds of 120 mpm and 240 mpm, and the above-mentioned insulating coating treatment liquid was applied. Then, at 820°C, 30 seconds, N 2 : A sintering process was carried out under the condition of 100vol% gas atmosphere to manufacture a grain-oriented electrical steel sheet with an insulating coating.

[0089] In Table 1, each dihydrogen phosphate aqueous solution was used as the phosphate, and SNOWTEX C manu...

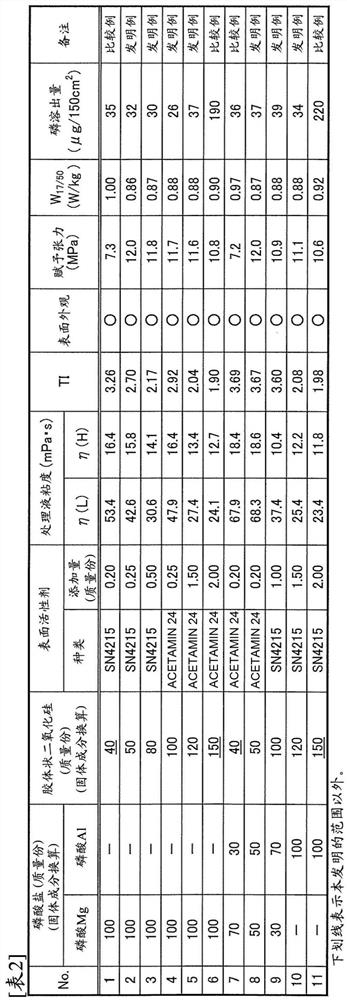

Embodiment 2

[0112] A finish-annealed grain-oriented electrical steel sheet having a thickness of 0.27 mm was prepared. The magnetic flux density B of the grain-oriented electrical steel sheet 8 It is 1.928T. After phosphoric acid pickling was performed on this grain-oriented electrical steel sheet, the total of both sides after sintering was 12.0 g / m 2 Various chromium-free insulating coating treatment solutions described in Table 2 were applied in the same manner. At this time, the grain-oriented electrical steel sheet was conveyed using a roll coater at two levels of conveying speeds of 100 mpm and 300 mpm, and the above-mentioned insulating coating treatment liquid was applied. Then, at 900°C, 30 seconds, N 2 : 90vol%-H 2 : A sintering treatment was carried out under the condition of 10 vol% gas atmosphere, and a grain-oriented electrical steel sheet with an insulating film was produced.

[0113] In Table 2, as the phosphate, each dihydrogen phosphate aqueous solution was used, an...

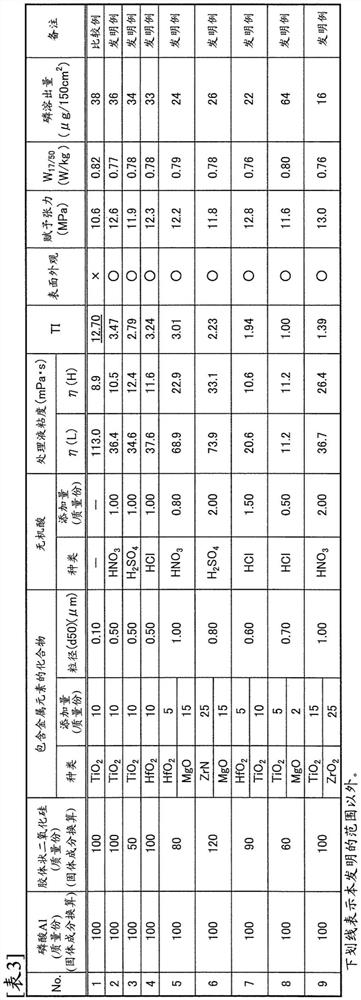

Embodiment 3

[0126] A finish-annealed grain-oriented electrical steel sheet having a thickness of 0.23 mm was prepared. The magnetic flux density B of the grain-oriented electrical steel sheet 8 It is 1.923T. After phosphoric acid pickling was performed on this grain-oriented electrical steel sheet, the total of both sides after sintering was 10.0 g / m 2 Various chromium-free insulating coating treatment solutions described in Table 3 were applied in the same manner. At this time, the grain-oriented electrical steel sheet was conveyed using a roll coater at two levels of conveying speeds of 150 mpm and 380 mpm, and the above-mentioned insulating coating treatment liquid was applied. Then, at 950°C, 10 seconds, N 2 : 85vol%-H 2 : The sintering treatment was carried out under the condition of 15vol% gas atmosphere, and the grain-oriented electrical steel sheet with the insulating film was produced.

[0127] In Table 3, an aluminum dihydrogen phosphate aqueous solution was used as the pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com