Hydrogen circulating system of fuel cell system

A fuel cell system and circulation system technology, which is applied to fuel cells, fuel cell additives, electrical components, etc., can solve the difficulty of further reducing the humidity of circulating hydrogen, aggravating the difficulty of draining the anode side of the fuel cell, and increasing the power consumption of the fuel cell system, etc. problems, to simplify the control of the hydrogen circulation system, reduce the risk of flooding, and take up less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

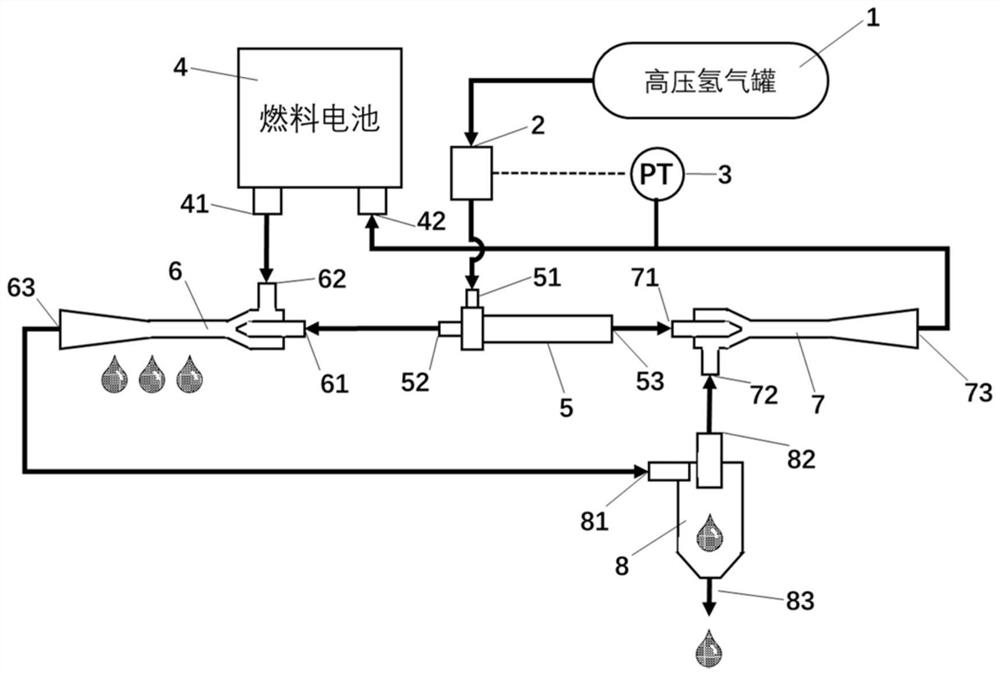

[0022] A fuel cell system hydrogen circulation system, such as figure 1 As shown, it includes a hydrogen source 1, a valve group 2, a vortex tube 5, a first ejector 6, a second ejector 7 and a gas-water separator 8, as well as connecting pipes and various sensors;

[0023] The output end of the hydrogen source 1 is connected to the vortex tube 5 through the valve group 2, specifically the inlet 51 of the vortex tube, the cold end outlet 52 of the vortex tube is connected to the jet inlet 61 of the first ejector, and the hot end outlet of the vortex tube 53 is connected to the jet inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com