Full-range passive safety injection system

A passive, full-scale technology, applied in the field of full-scale passive safety injection systems, can solve the problems of large area of the primary circuit, inability to popularize and apply, and large limitations, so as to improve operation and maintenance, ensure safety and The effect of automation level, simplified construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

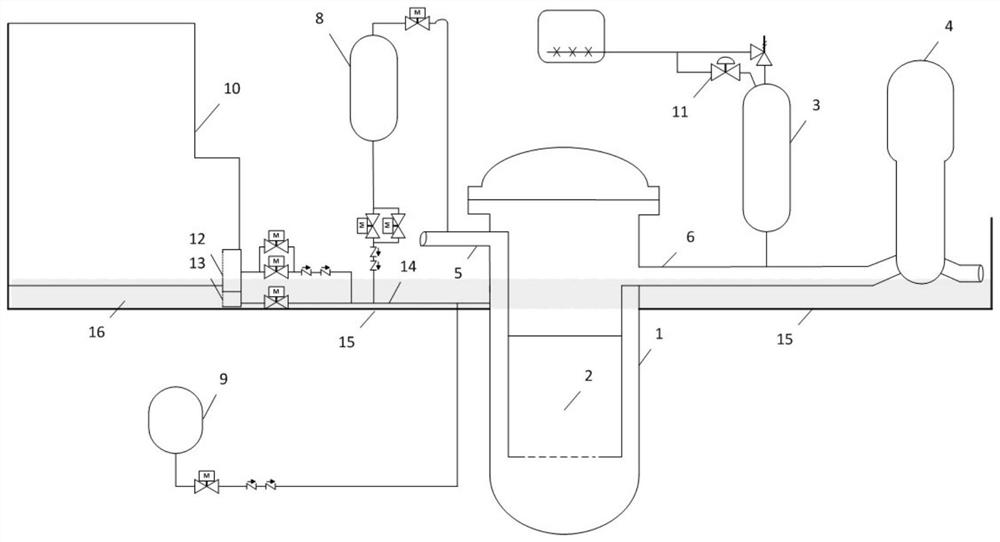

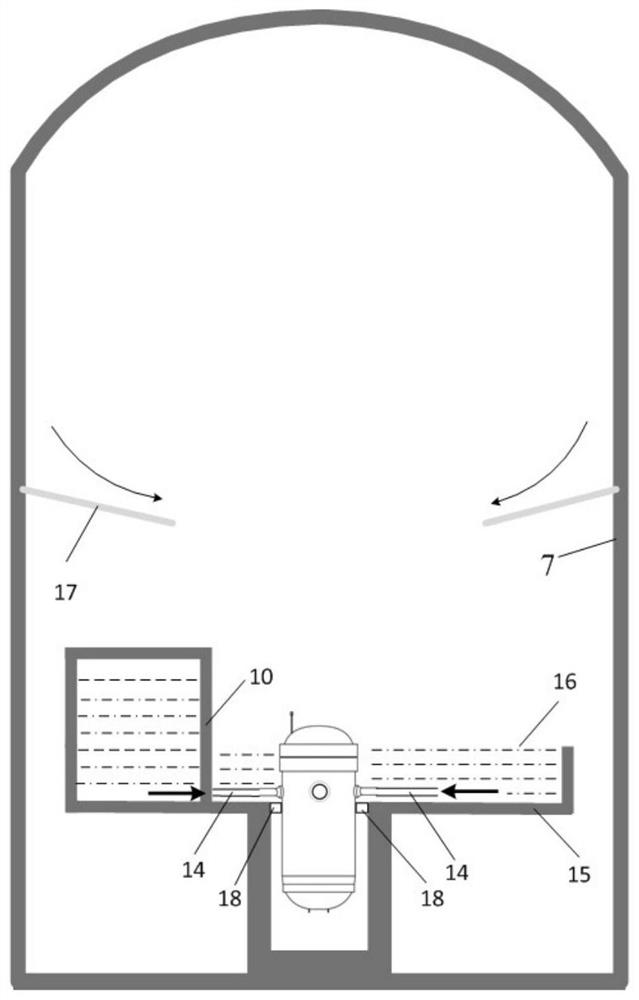

[0038] like figure 1As shown, two core make-up water tanks 8 (only one is shown in the figure) are arranged higher than the level of the main pipeline of the primary circuit. Each core make-up water tank 8 is filled with boron-containing water, and is connected to the primary circuit through an inlet pressure balance pipeline and an outlet injection pipeline. The outlet injection line is connected to the pressure vessel direct injection (DVI) line 14 through two parallel normally closed pneumatic isolation valves and two series check valves. The pressure balance pipeline is connected to the nozzle at the top of the cold section 5 of the main pipeline, and is equipped with a normally open electric valve to maintain the pressure of the core makeup water tank 8 consistent with the operating pressure of the primary circuit to avoid water hammer when injection is triggered. The insulation and direction of the pressure balance pipeline ensure that the normal water temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com