a pressure sensor

A technology of pressure sensor and flexible pipe, which is applied in the direction of measuring fluid pressure, instrument, fluid pressure measurement by changing ohmic resistance, etc. It can solve problems such as sensor failure, increase surface area, increase pipe wall adsorption area, and improve reliability Effects on Sexuality and Lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

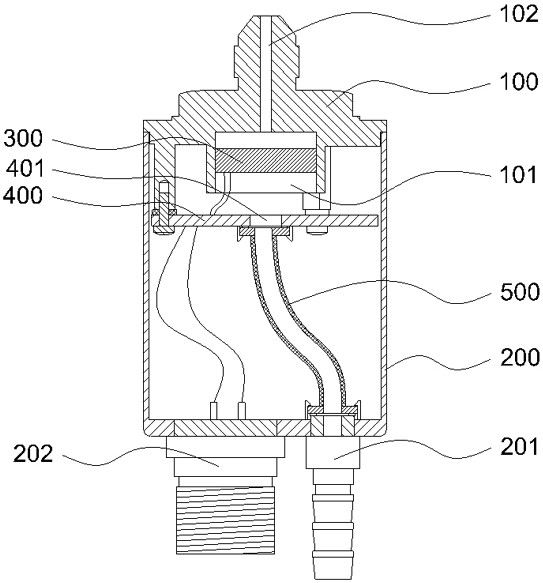

[0034] Example 1, reference Figure 1 , the pressure sensor of the present scheme, including a detachable connection between the lid 100 and the housing 200, the cover 100 and the housing 200 form an enclosed internal space, the lower end of the cover 100 is mounted circuit board 400, the circuit board 400 divides the internal space into mutually isolated upper space and lower space, the circuit board 400 is opened through hole 401, to connect the upper space and the lower space.

[0035] In practical application, the circuit board 400 is not in direct contact with the housing 200, so the upper space and the lower space are only the upper and lower spaces on the space, and the two spaces are connected. However, in order to 100% ensure the communication state of the upper space and the lower space (to avoid hindering the pressure delivery), to avoid the connection state is blocked due to different thermal expansion coefficients and other reasons, the circuit board 400 opens a throug...

Embodiment 2

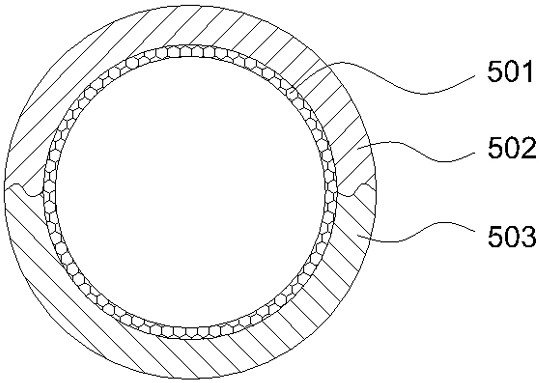

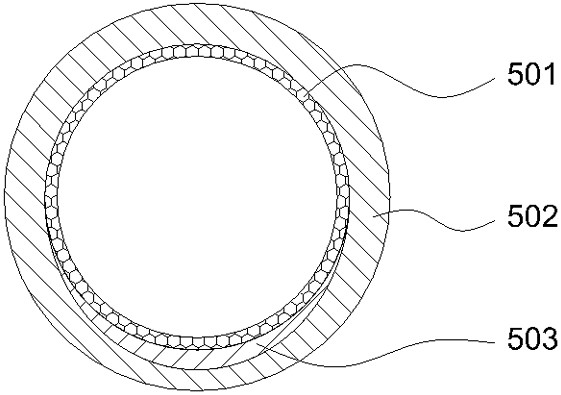

[0043] Example 2, the flexible pipeline 500 of the present embodiment includes a structural mesh pipe 501 and a structural mesh pipe 501 provided on the hydrophilic adsorption layer 502 and an oil-friendly adsorption layer 503.

[0044] Wherein, the structural mesh pipe 501 is used to support the hydrophilic adsorption layer 502 and the lipophilic adsorption layer 503, so that the flexible pipeline 500 has been kept in a smooth state, to avoid the pipe flattening and affecting the pressure transmission, and the structural mesh pipe 501 will not affect the gas, water and oil from the pipe wall through, and then the water is adsorbed by the hydrophilic adsorption layer 502, the oil is adsorbed by the lipophilic adsorption layer 503.

[0045] reference Figure 2 and Figure 3, shown in the figure is a hydrophilic adsorption layer 502 and an oleophilic adsorption layer 503 are attached to the outer surface of the structural mesh tube 501, in practical applications, the hydrosorption lay...

Embodiment 3

[0053] Example 3, reference Figure 4 In order to further extend the service life of the pressure sensor, the present embodiment on the basis of Example 1, gives a flexible pipeline 500 distribution mode, the flexible pipe 500 is spiraled around the lower space, the length of the flexible pipeline 500 is increased, that is, the adsorption area of the pipeline wall to water and oil is increased, which can greatly improve the durability of the pressure sensor. At the same time, the spiral winding can generate centrifugal force when the gas passes, and the water and oil are thrown onto the pipe wall, further reducing the chance of water and oil passing through the flexible pipe 500.

[0054] Since the cover body 100 and the housing 200 are preferably connected by threaded connection, the two ends of the flexible pipe 500 are connected to the circuit board 400 through hole 401 and the lower pipe nozzle 201, in the process of the cover body 100 screw into the housing 200, the flexible p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com