Novel process for recycling aluminum oxide and iron oxide by dissolving out red mud at low temperature

A technology of alumina and iron oxide, which is applied in the new process field of low-temperature dissolution of red mud to recover alumina and iron oxide, can solve the problem of low iron concentrate grade and iron recovery rate, poor red mud sedimentation performance, and flocculant consumption. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

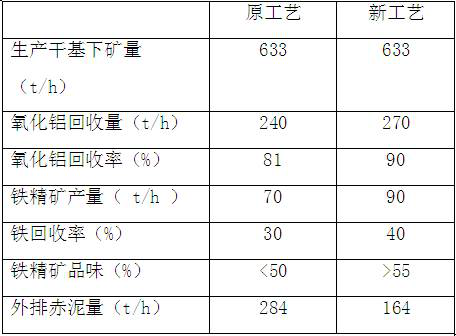

specific Embodiment 1

[0046] An alumina factory with an annual output of 2 million tons of alumina adopts the low-temperature dissolution process of Guinea ore, and its low-temperature dissolution dry-based red mud amount is 284t / h. After adopting this technical solution, 30t / h more alumina can be recovered, 90t / h of 55% iron ore concentrate can be produced, and the final discharge of red mud is 164t / h, and the emission reduction of red mud is reduced by 42% on the original basis.

[0047] Step 1) Ingredients: Mix the red mud slurry from the bottom flow of the separation and settling tank in the alumina plant into the circulating mother liquor (sodium oxide concentration 190g / l, alumina concentration 100g / l, 354t / h) and lime and stir evenly to obtain qualified pulp.

[0048] Step 2) High-temperature dissolution: use a diaphragm pump to send the qualified ore slurry into the pipeline dissolution device. The pipeline device adopts the method of 3 casings, in which the inner casing is 3 seamless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com