Comprehensive treatment method for resource utilization of antibiotic mushroom dregs

A technology of antibiotic residues and disposal methods, which is applied in chemical instruments and methods, combustion methods, carbon compounds, etc., can solve the problems of difficult disposal of bacteria residues and low utilization rate of resources, and achieve comprehensive utilization, efficiency assurance, strong adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

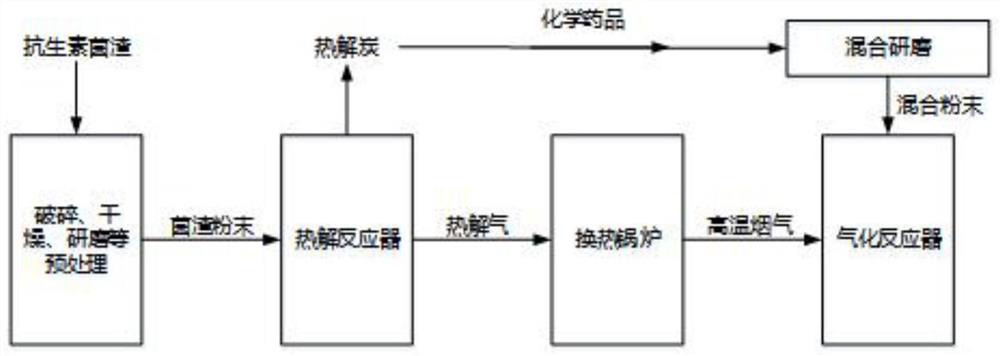

Method used

Image

Examples

Embodiment 1

[0029] (1) Get 1kg of penicillin slag to filter, crush, and place it in a blast drying oven at 105°C for 24 hours, grind the dried penicillin slag, and pass through a 40-mesh sieve to obtain the slag powder;

[0030] (2) Put the powder of bacteria residue into the pyrolysis reactor, N 2 Pass it into the pyrolysis reactor at a flow rate of 400mL / min, raise the temperature to 600°C at a rate of 10°C / min, and keep it for 60 minutes to obtain pyrolysis gas and pyrolysis carbon; the main component of the pyrolysis gas is CO 2 (12.53%), CO (3.32%), CH 4 (1.19%), H 2 (4.01%) and C 2+ Gas (0.94%) (C 2+ gas including C 2 h 4 、C 2 h 6 and C 3 h 6 Wait, C 2+ are collectively referred to);

[0031] (3) Pyrolytic carbon and KOH are mixed according to a mass ratio of 1:1, ground and sieved through a 40-mesh sieve to obtain a mixed powder, and put into an activation reactor;

[0032] (4) After the pyrolysis gas enters the heat exchange boiler, the boiler temperature is 850°C. Adj...

Embodiment 2

[0035] Same as Example 1, the difference is that the antibiotic residue is lincomycin residue.

[0036] (1) Take 1 kg of lincomycin slag to filter, crush, and place it in a 105° C. blast drying oven for 24 hours, grind the dried penicillin slag, pass through a 40-mesh sieve, and obtain the slag powder;

[0037] (2) Put the powder of bacteria residue into the pyrolysis reactor, N 2 Pass it into the pyrolysis reactor at a flow rate of 400mL / min, raise the temperature to 600°C at a rate of 10°C / min, and keep it for 60 minutes to obtain pyrolysis gas and pyrolysis carbon; the main component of the pyrolysis gas is CO 2 (13.15%), CO (3.18%), CH 4 (1.64%), H 2 (4.27%) and C2+ Gas (1.04%);

[0038] (3) Pyrolytic carbon and KOH are mixed according to a mass ratio of 1:1, ground and sieved through a 40-mesh sieve to obtain a mixed powder, and put into an activation reactor;

[0039] (4) After the pyrolysis gas enters the heat exchange boiler, the boiler temperature is 850°C. Adjust...

Embodiment 3

[0042] (1) Get 1kg of gentamicin slag to filter, crush, and place it in a blast oven at 105°C for 24 hours, grind the dried penicillin slag, and pass through a 40-mesh sieve to obtain the slag powder;

[0043] (2) Put the powder of bacteria residue into the pyrolysis reactor, N 2 Pass it into the pyrolysis reactor at a flow rate of 400mL / min, raise the temperature to 600°C at a rate of 10°C / min, and keep it for 60 minutes to obtain pyrolysis gas and pyrolysis carbon; the main component of the pyrolysis gas is CO 2 (14.65%), CO (4.13%), CH 4 (2.44%), H 2 (3.64%) and C 2+ Gas (1.08%);

[0044] (3) Pyrolytic carbon and KOH are mixed according to a mass ratio of 1:1, ground and sieved through a 40-mesh sieve to obtain a mixed powder, and put into an activation reactor;

[0045] (4) After the pyrolysis gas enters the heat exchange boiler, the boiler temperature is 850°C. Adjust the heat exchanger in the heat exchange boiler, and monitor the outlet flue gas temperature, and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com