Organic waste liquid pulse combustion pyrolysis device and method

A technology of pulsating combustion and organic waste liquid, which is applied in the field of waste liquid pyrolysis device and organic waste liquid pulsating combustion pyrolysis device. Require high-level problems to achieve the effect of improving energy utilization, avoiding heating dead ends, and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

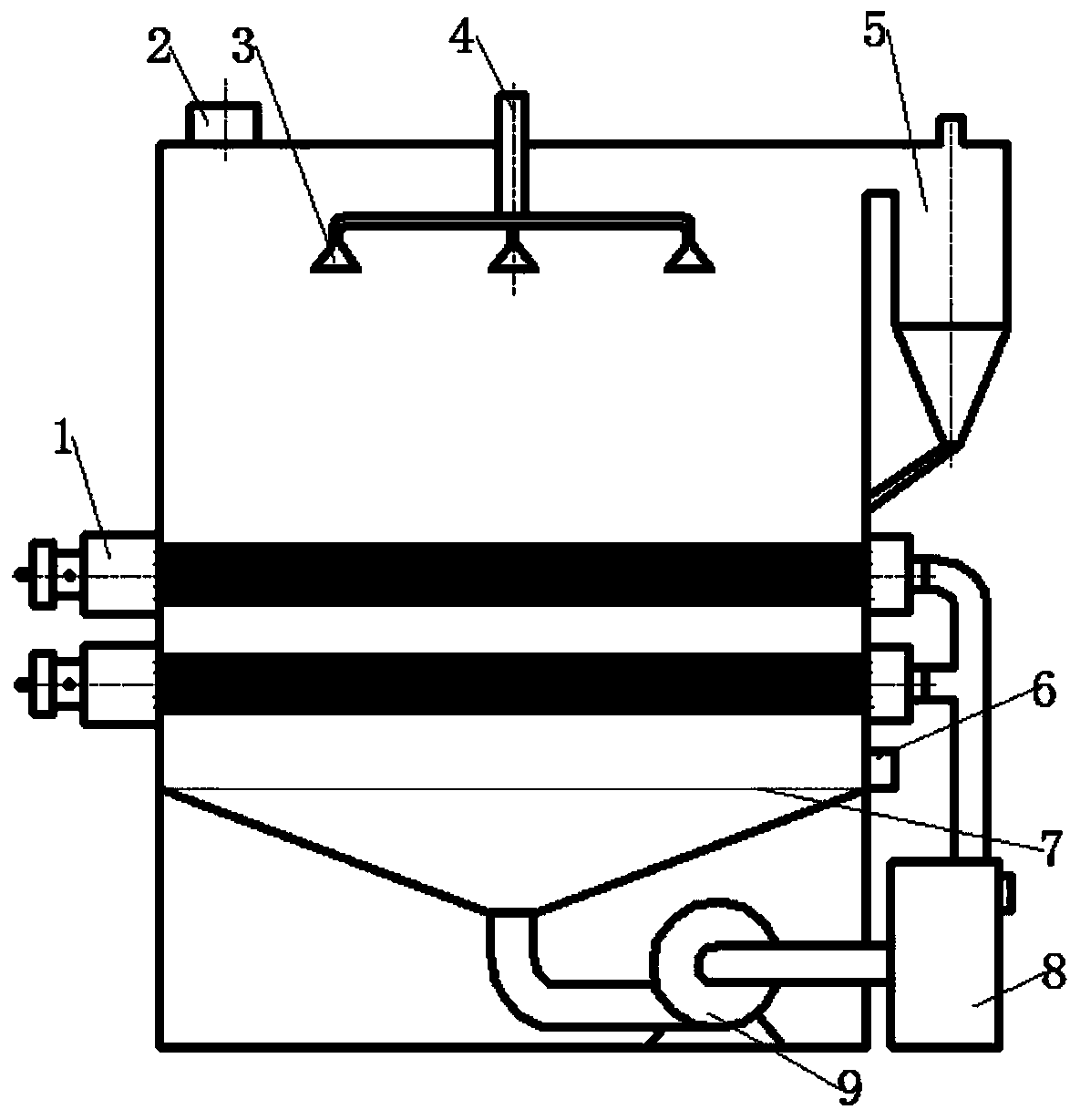

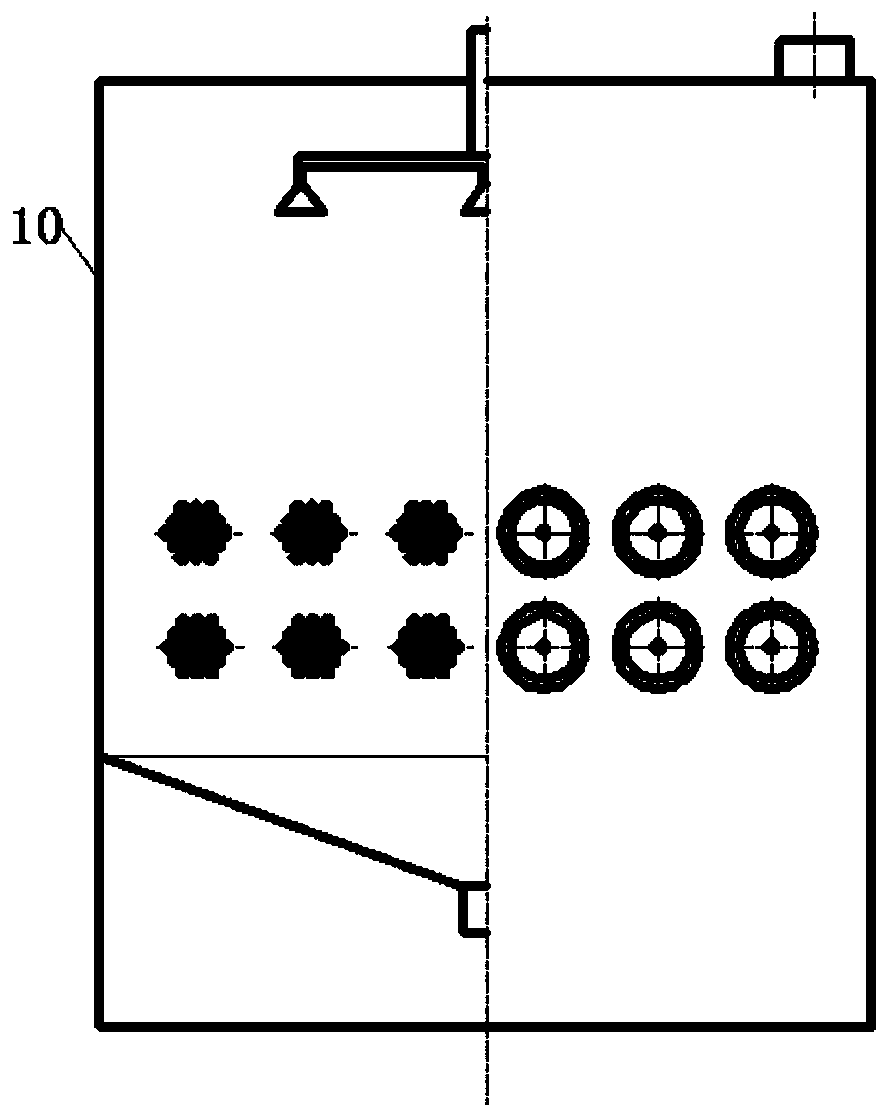

[0036] An organic waste liquid pulsating combustion pyrolysis device, including a fluidized bed 10, the fluidized bed is provided with a filler inlet 2 and a material outlet 6, and its innovation is that it also includes a waste liquid sprayer, a gas furnace 8 and The pulsating burner 1, the top of the fluidized bed is equipped with a waste liquid sprayer, the bottom of the fluidized bed is equipped with a porous air distribution plate 7, the end of the air gas furnace is connected with a hot air supply pump 9, and the hot air supply pump passes through The air supply pipe is connected to the porous air distribution plate, and several pulsating burners are arranged horizontally in the fluidized bed;

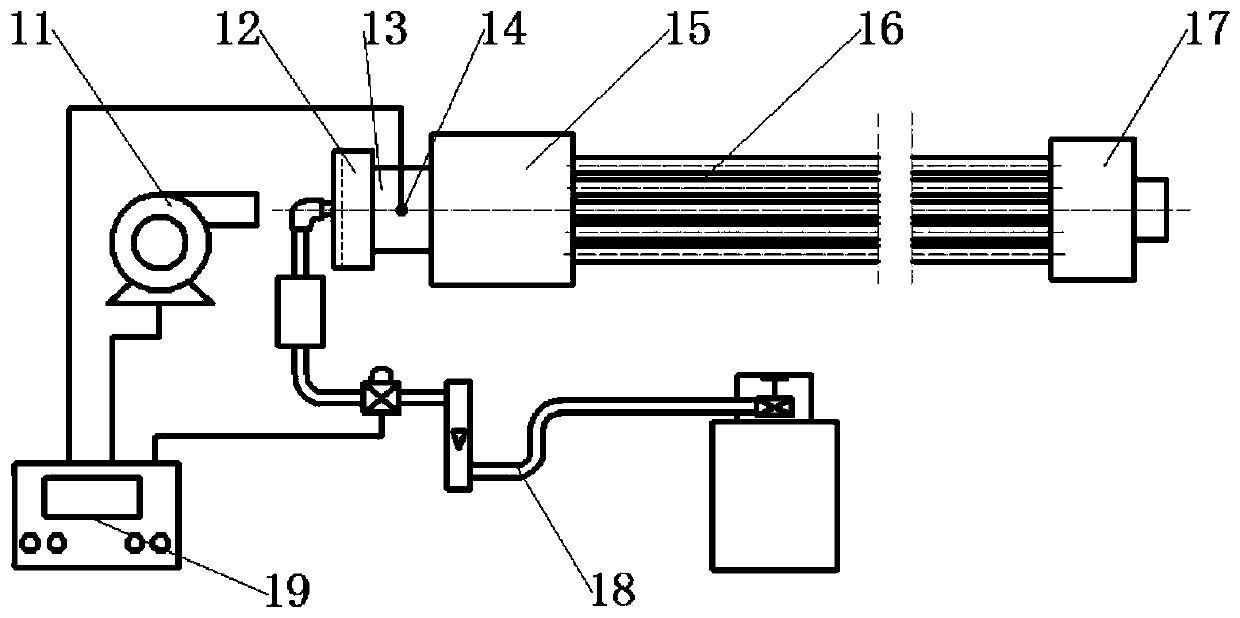

[0037] The pulsation burner includes a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com