High-strength tire bead steel wire for winter nailless tire and production process of high-strength tire bead steel wire

A bead steel wire and production process technology, applied in the field of bead steel wire, can solve the problems of narrow side of the bead steel wire, poor tire puncture resistance, affecting tire performance, etc., so as to increase the side area, strengthen the puncture resistance performance, and improve the barrier. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

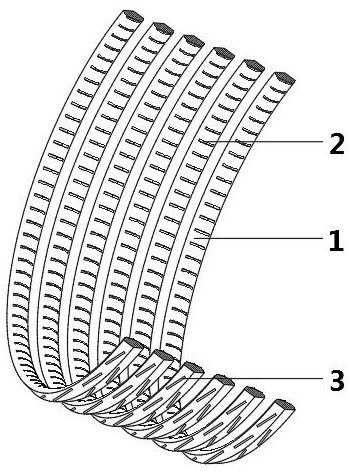

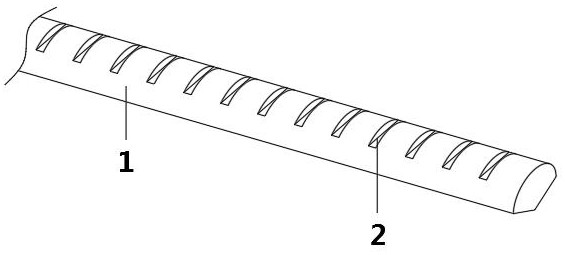

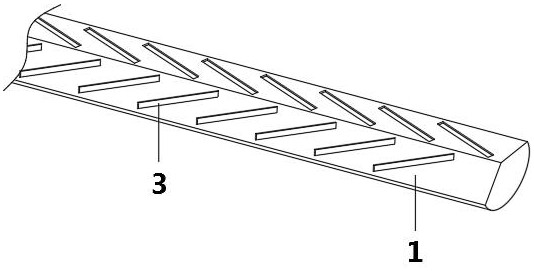

[0030] see Figure 1 to Figure 3 , the invention relates to a high-strength bead wire for winter studless tires, comprising a steel wire main body 1, the upper part of the end surface of the steel wire main body 1 is semi-elliptical, the lower part of the end surface of the steel wire main body 1 is triangular, and the upper side of the steel wire main body 1 is opened There is a curved groove 2, and the lower side of the steel wire main body 1 is provided with a guide groove 3, the guide groove 3 is an obliquely arranged elongated groove, and the guide groove 3 is arranged in many places in a left-right symmetrical arrangement, the steel wire main body 1 The outer side is provided with a coating 4, and by setting the steel wire into this wide flat structure, the side area of the steel wire main body 1 can be increased, and the barrier performance of the steel wire main body 1 has been improved. 3. When an external object penetrates the tire, the inserted object can be guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com