Method for solving expansion of winding type battery cell

A battery expansion and winding technology, which is applied in the direction of winding/folding electrodes, circuits, electrical components, etc., can solve the problems of expansion and failure to fit into the battery case, and achieve the effect of excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

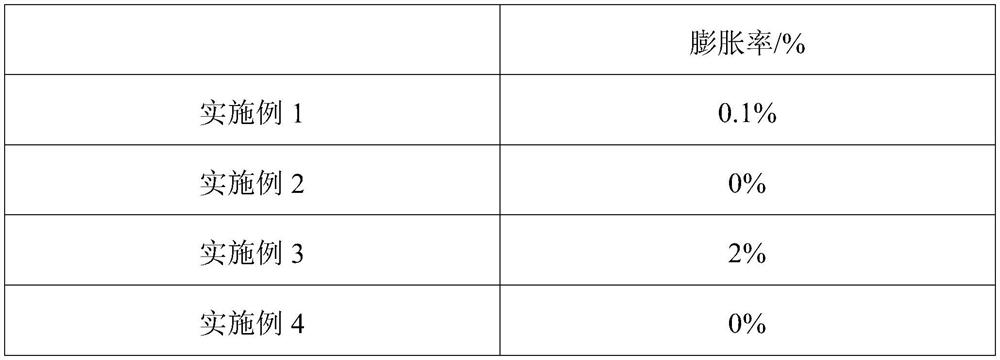

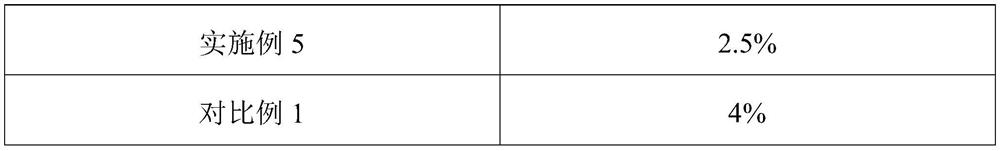

Examples

Embodiment 1

[0035] This embodiment provides a low-expansion wound-type electric core, and the preparation method of the low-expansion wound electric core is as follows:

[0036] (1) Stack the silicon-based negative electrode sheet, PE separator, and NCM positive electrode sheet in sequence. According to the design requirements of the battery, select a suitable winding needle for winding, and fix the obtained winding core with a small piece of PP-based adhesive tape to obtain a roll winding battery;

[0037] (2) Put the above winding cell into a vacuum vapor deposition coating machine, set the evaporation temperature to 150°C, the pyrolysis temperature to 500°C, and the vacuum pressure to 2 millitorr, and use parylene in the winding cell A polymer layer with a thickness of 3 μm was evenly plated on the surface of the polymer to obtain the low expansion rate winding battery core.

Embodiment 2

[0039] This embodiment provides a low-expansion wound-type electric core, and the preparation method of the low-expansion wound electric core is as follows:

[0040] (1) Stack the graphite negative electrode sheet, PE diaphragm and lithium iron phosphate positive electrode sheet in sequence, select a suitable winding needle for winding according to the design requirements of the battery, and fix the obtained winding core with a small piece of PE tape to obtain a roll winding battery;

[0041] (2) Put the above core into a vacuum vapor deposition coating machine, set the evaporation temperature to 170°C, the pyrolysis temperature to 600°C, and the vacuum pressure to 3 millitorr, and use parylene to evenly coat a layer with a thickness of 3 μm. polymer layer to obtain the low-expansion wound-type battery core.

Embodiment 3

[0043] This embodiment provides a low-expansion wound-type electric core, and the preparation method of the low-expansion wound electric core is as follows:

[0044] (1) Stack the silicon-based negative electrode sheet, PE separator, and NCM positive electrode sheet in sequence. According to the design requirements of the battery, select a suitable winding needle for winding, and fix the obtained winding core with a small piece of PP tape to obtain a winding battery cell;

[0045] (2) Put the above core into a vacuum vapor deposition coating machine, set the evaporation temperature to 150°C, the pyrolysis temperature to 500°C, and the vacuum pressure to 2 millitorr, and use parylene to evenly coat a layer with a thickness of 0.5 μm polymer layer to obtain the low expansion rate winding cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com