Device for detecting mechanical strength of powder metallurgy gear

A technology of mechanical strength and detection devices, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the unfavorable detection work of gears of different sizes, the inconvenient continuous detection of production work, and the unfavorable overall detection Work and other problems, to achieve the effect of convenient continuous detection of production work, convenient pairing contact connection phenomenon, convenient support and fixed work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

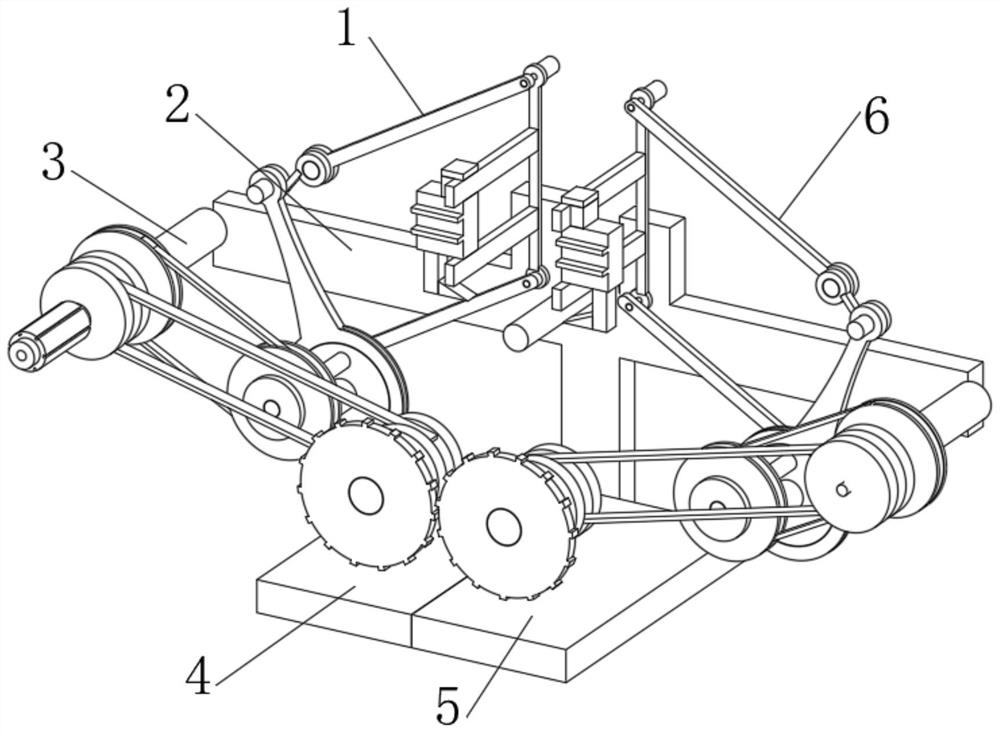

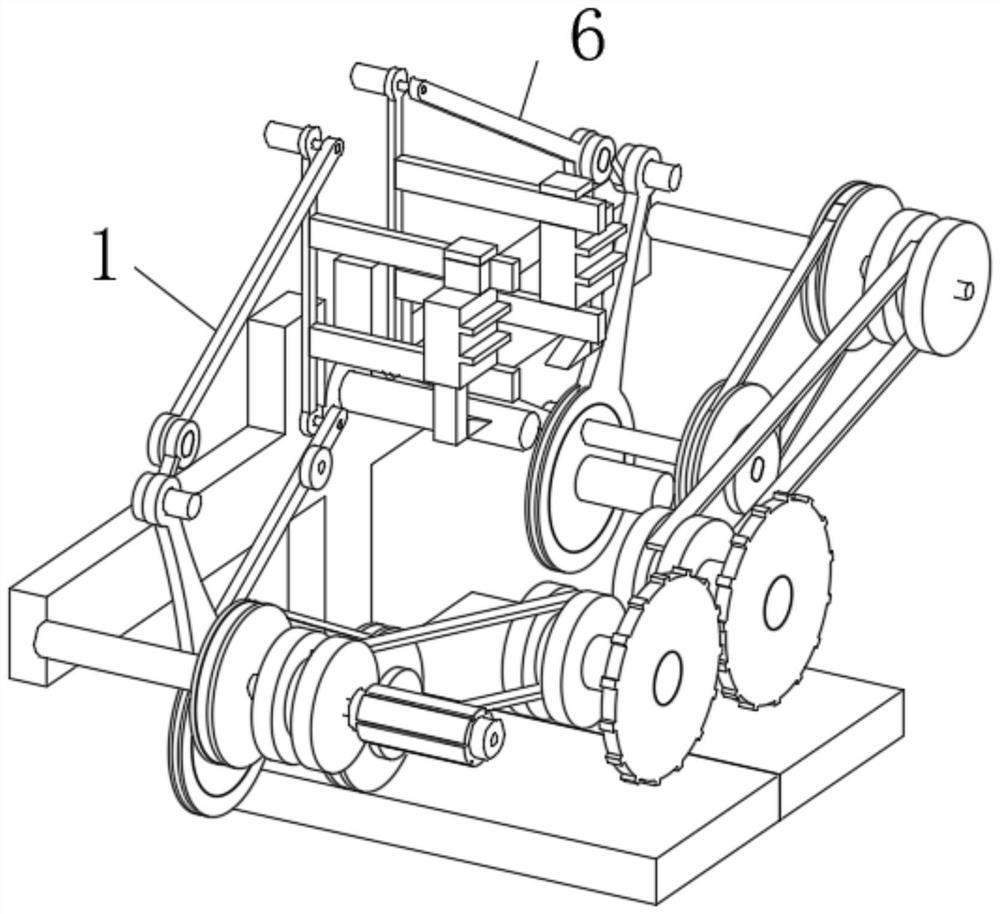

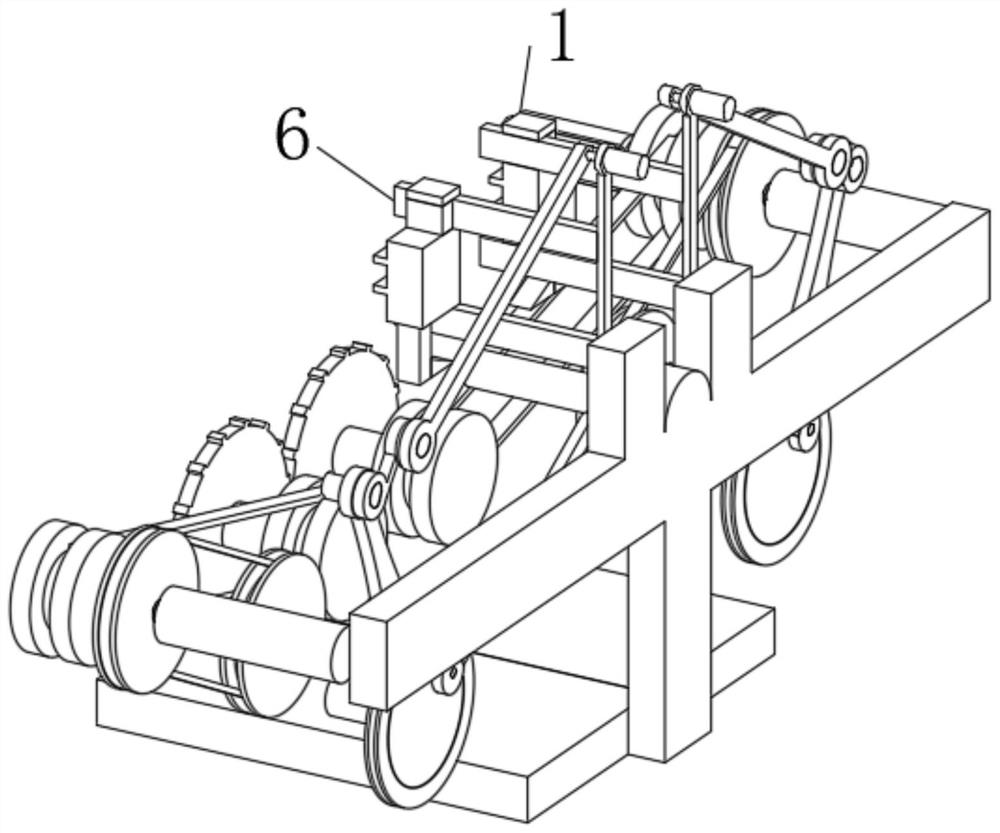

[0036] see figure 1 , figure 2 , image 3, an embodiment provided by the present invention: a powder metallurgy gear mechanical strength detection device, including a first detection structure 1, a column frame 2, a mounting frame 3, a first bottom plate 4, a second bottom plate 5 and a second detection structure 6. The side end of the first base plate 4 is fixedly connected with the second base plate 5, and the bottom ends of the first base plate 4 and the second base plate 5 are fixedly connected with the column frame 2, and the front end of the column frame 2 is respectively connected with the mounting frame 3. The first detection structure 1 and the second detection structure 6 are connected in a limited position, through the combined connection of the first detection structure 1, the column frame 2, the installation frame 3, the first bottom plate 4, the second bottom plate 5 and the second detection structure 6 , convenient for overall installation and fixing, and con...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 8 As shown, the upper end of the column frame 2 is fixedly connected with a protective frame 25 and a barrier shielding frame 26, and the top positions of the protective frame 25 and the barrier shielding frame 26 are fixedly connected with a supporting top plate 24.

[0042] When this embodiment is implemented, the user installs the support top plate 24, the protective frame 25 and the barrier shield frame 26 to facilitate the connection and installation work, and the support top plate 24 facilitates the protective connection work on the top, so as to realize the protection of the top surface and prevent the gear The pop-up helps to carry out the protection of personnel, and by the setting of protective frame 25 and barrier shielding frame 26, it is convenient to carry out the supporting and fixing work of supporting top plate 24.

[0043] Working principle: The user will connect the first detection structure 1, the column fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com