Formaldehyde microbial purifier for building ventilation engineering

A purifier and microbial technology, applied in the field of formaldehyde microbial purifiers, can solve the problems of reduced formaldehyde absorption efficiency, reduced bacterial activity, troublesome watering on time, etc., to prevent gelatin components from sticking, increase porosity, and slow down water evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

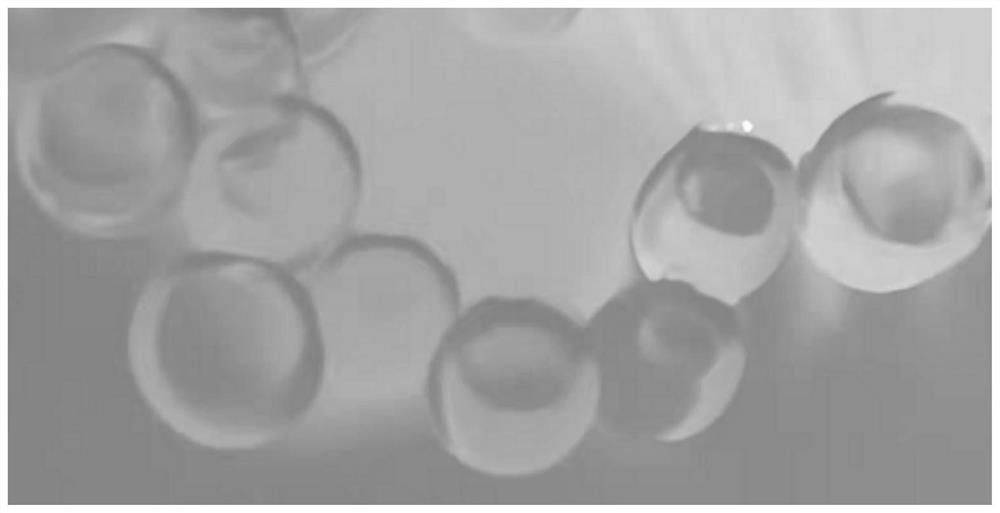

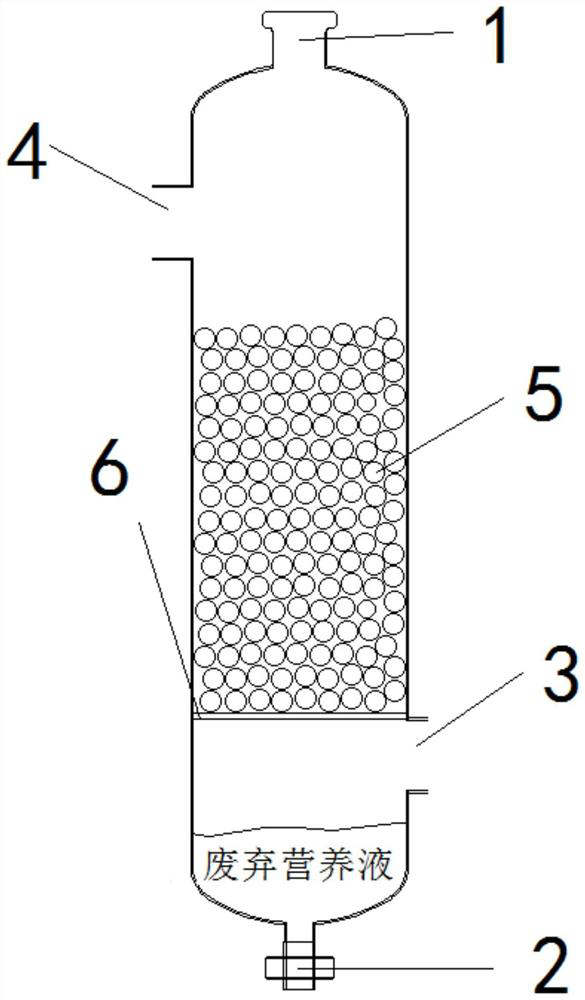

[0038] A kind of preparation method of the formaldehyde microbial scavenger used in building ventilation engineering for purifying air, the steps are as follows:

[0039] (1) Cultivate the formaldehyde-degrading bacterial strain Enterovirga rhinocerotis (China Center for Typical Culture Collection, preservation number is CCTCC AB 2012048) to the logarithmic growth phase, and centrifuge to obtain the bacteria. The specific method is: configure the slant culture to degrade formaldehyde under the condition of 32°C After the strain was activated for 24 hours, it was inoculated in liquid medium, cultured on a shaking table at 32°C for 28 hours, the rotating speed of the shaking table was 100rpm, poured into a centrifuge tube and centrifuged at 5000r / min for 5min, poured out the supernatant to get the precipitate, and used physiological The precipitate was washed with brine and centrifuged again to obtain the bacteria;

[0040] (2) Weighing gelatin and sodium alginate to dissolve in...

Embodiment 2

[0044] A kind of preparation method of the formaldehyde microbial scavenger used in building ventilation engineering for purifying air, the steps are as follows:

[0045](1) Cultivate the formaldehyde-degrading bacterial strain Enterovirga rhinocerotis (China Center for Typical Culture Collection, preservation number is CCTCC AB 2012048) to the logarithmic growth phase, and centrifuge to obtain the bacteria, specifically: after the formaldehyde-degrading bacterial strain is activated by configuring a slope medium , inoculated in liquid medium, cultured on a shaking table at 30°C for 32 hours, the rotating speed of the shaking table was 120rpm, poured into a centrifuge tube and centrifuged at 6000r / min for 4min, poured out the supernatant to get the precipitate, and washed the precipitate with normal saline Centrifuge again to obtain the bacteria;

[0046] (2) dissolving gelatin and sodium alginate in water, heating and dissolving at 50°C, adding inulin, and stirring evenly to ...

Embodiment 3

[0050] A kind of preparation method of the formaldehyde microbial scavenger used in building ventilation engineering for purifying air, the steps are as follows:

[0051] (1) Cultivate the formaldehyde-degrading bacterial strain Enterovirga rhinocerotis (China Center for Typical Culture Collection, preservation number is CCTCC AB 2012048) to the logarithmic growth phase, and centrifuge to obtain the bacteria, specifically: after the formaldehyde-degrading bacterial strain is activated by configuring a slope medium , inoculated in liquid medium, cultured on a shaking table at 36°C for 25 hours, the rotating speed of the shaking table was 150rpm, poured into a centrifuge tube and centrifuged at 4000r / min for 5min, poured out the supernatant to get the precipitate, and washed the precipitate with normal saline Centrifuge again to obtain the bacteria;

[0052] (2) dissolving gelatin and sodium alginate in water, heating and dissolving at 60°C, adding inulin, and stirring evenly to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com