Composite porous carbon aerogel material as well as preparation method and application thereof

A porous aerogel and interaction force technology, applied in the field of materials, can solve the problems of insufficient contact with graphene specific capacitance and limit the practical application in the field of super capacitors, and achieve the effect of avoiding stacking and improving structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of graphene oxide samples is carried out as follows:

[0042] Graphene oxide was prepared according to the improved Hummers method. A beaker containing 240ml of concentrated sulfuric acid (98wt%) was stirred in an ice-water bath, then natural graphite powder (9g) and sodium nitrate (9g) were added to the beaker, and the stirring was continued for 2h. Then, 27 g of potassium permanganate was slowly added, and the temperature was kept not exceeding 20° C. and stirred for one hour. After that, it was stirred in an oil bath at 30-40° C. for 2 h to form a viscous slurry. Then add 400ml of deionized water, raise the temperature to 85-90°C, and stir for 30 minutes. Finally, 1000 mL of deionized water was added, and 60 mL of hydrogen peroxide (30%) was slowly added, and the color of the solution changed from dark brown to bright yellow. After the product was filtered, washed with 1000 ml of 1M hydrochloric acid solution and deionized water, it turned black. F...

Embodiment 2

[0044] The preparation of bimetallic ZIF-Zn / Co samples is carried out as follows:

[0045] Dissolve 4.54g of dimethylimidazole in 70mL of deionized water. Under stirring conditions, 2 mL of cetyltrimethylammonium bromide (CTAB) with a concentration of 0.1 g·mL-1 was added, stirred for 10 minutes, and recorded as solution A. Subsequently, 0.0967 g of zinc nitrate hexahydrate and 0.1933 g of cobalt nitrate hexahydrate were dissolved in 10 mL of water, which was designated as solution B. Under the condition of stirring, solution B was quickly injected into solution A, and stirred at room temperature for 5 hours to obtain a purple solution, which was centrifuged to obtain a solid that was alternately washed with ethanol and water several times, and then dried in a vacuum oven.

Embodiment 3

[0047] Sample preparation was carried out as follows:

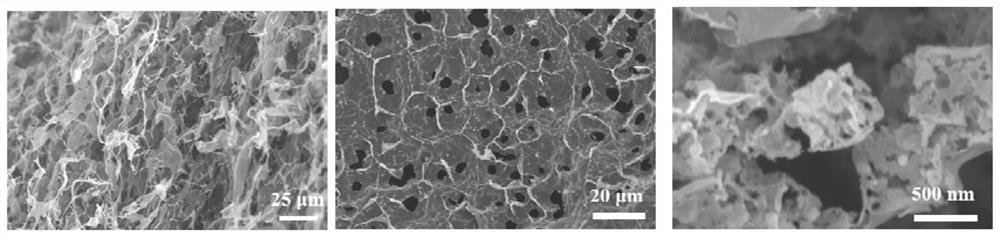

[0048] The first step: 1.3wt% nanocellulose (CNF) is dispersed in deionized water to form a 0.2% CNF solution, and the graphene oxide (GO) (10mg / ml) prepared in Example 1 is ultrasonically dispersed into the CNF solution The CNF / GO suspension was obtained in . The mass ratio of CNF and GO is (40mg:20mg). Then 100 mg ZIF-Zn / Co was added thereto, and a uniform CNF / GO / ZIF-Zn / Co suspension was obtained by continuous ultrasonication and stirring.

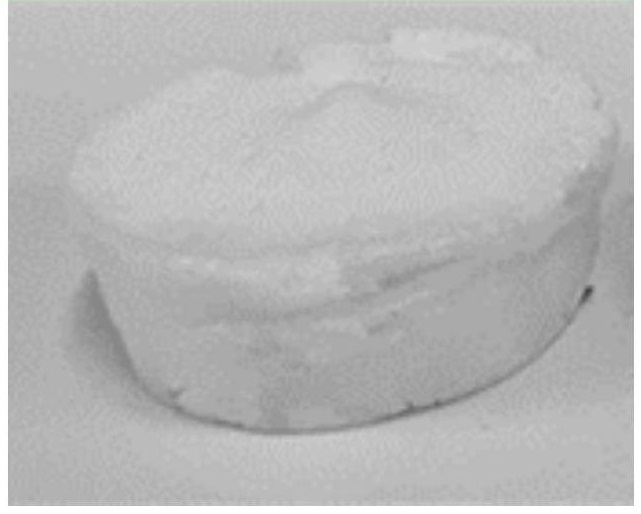

[0049] Step 2: Pour the uniformly mixed CNF / GO / ZIF-Zn / Co suspension into a 30ml cylindrical mold, freeze and pretreat in liquid nitrogen at -196°C for 15min, and place the freeze-drying pressure at CNF / GO / ZIF-Zn / Co airgel was obtained in a freeze dryer with a condenser temperature of -50°C at 5 Pa and a freeze-drying time of 48 hours.

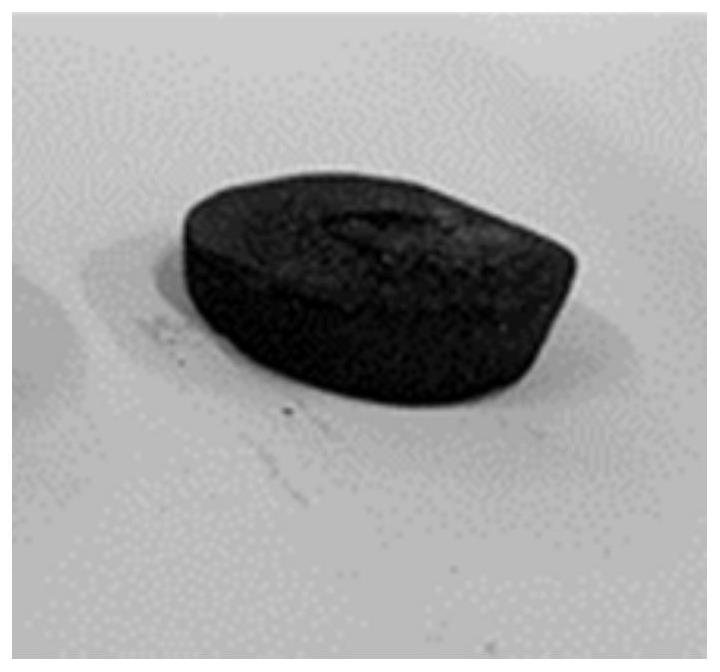

[0050] The third step: put the CNF / GO / ZIF-Zn / Co airgel prepared in the second step in a tube furnace, and perform high-temperature carbon firing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com